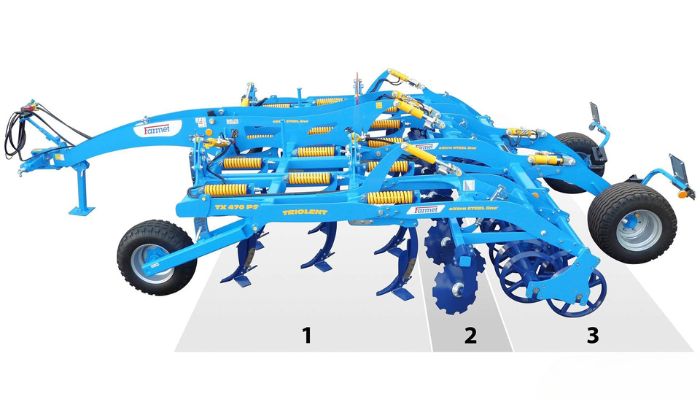

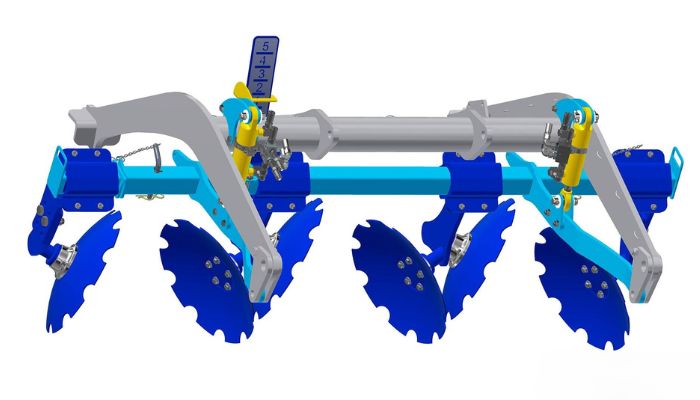

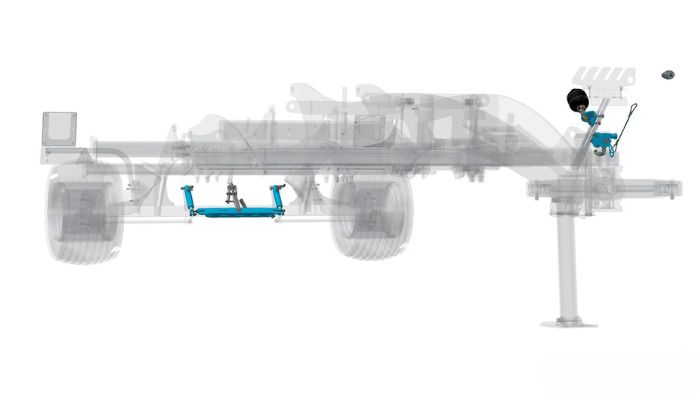

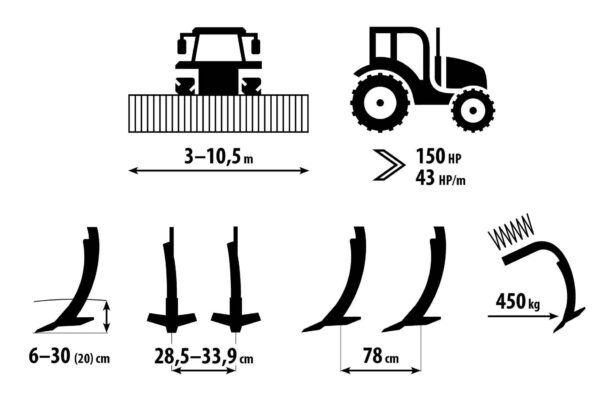

Three-row trailed tine cultivators for working up to 30 cm depth.

TRIOLENT PS trailed tine cultivators – for stubble cultivation up to 20 cm deep and soil cultivation up to 30 cm deep

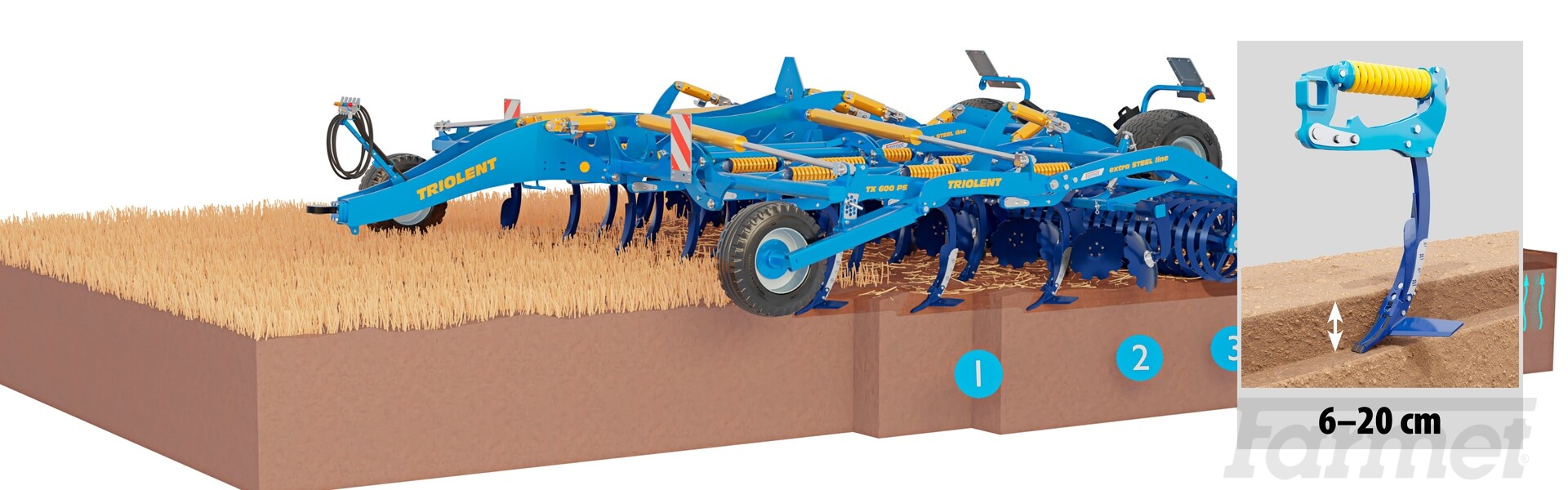

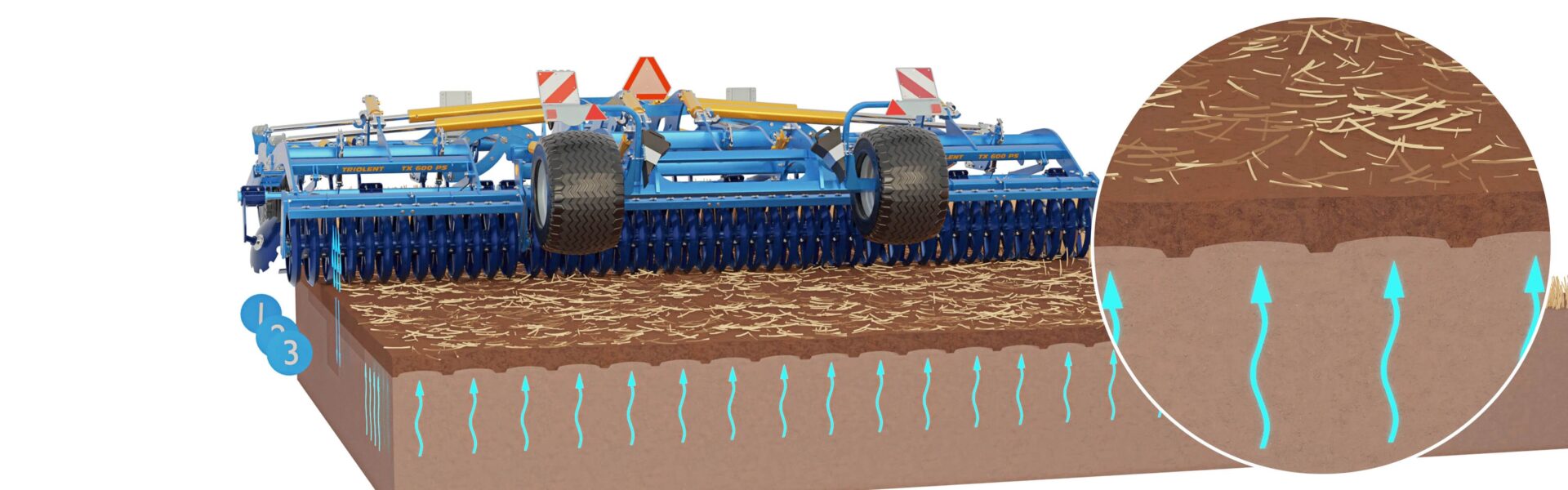

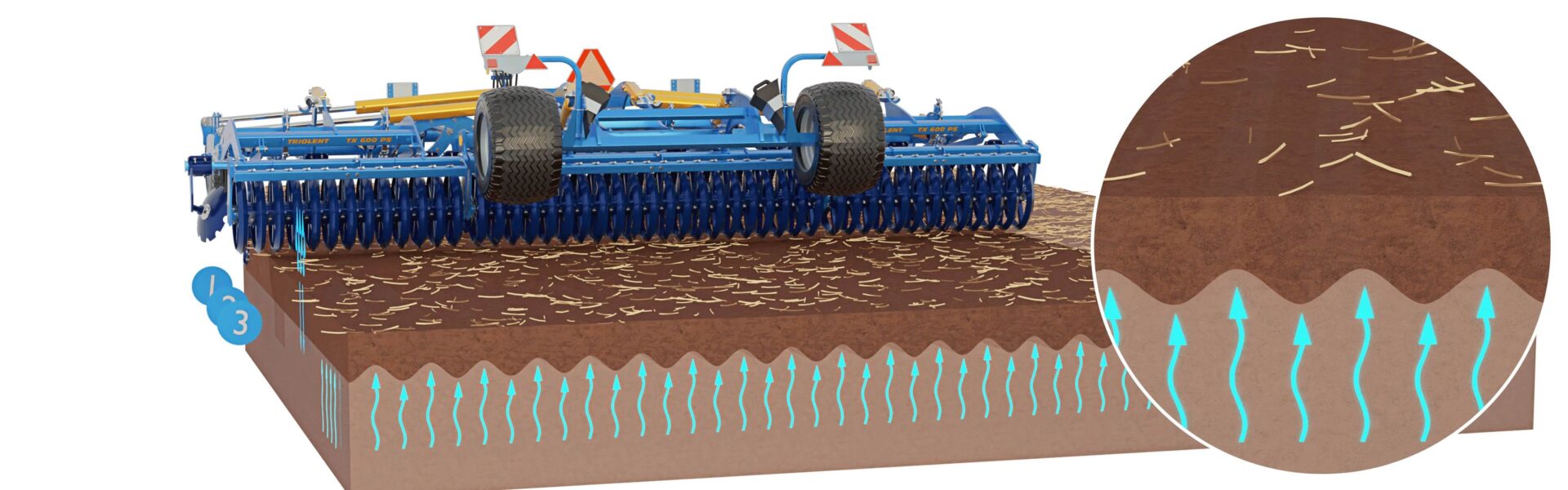

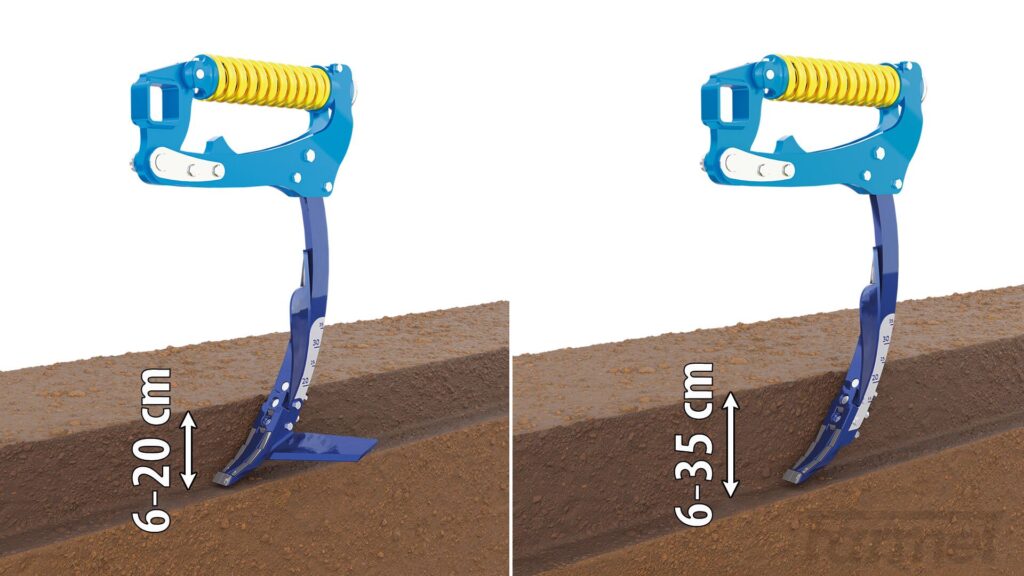

Triolent PS: shaving stubble 6–20 cm deep

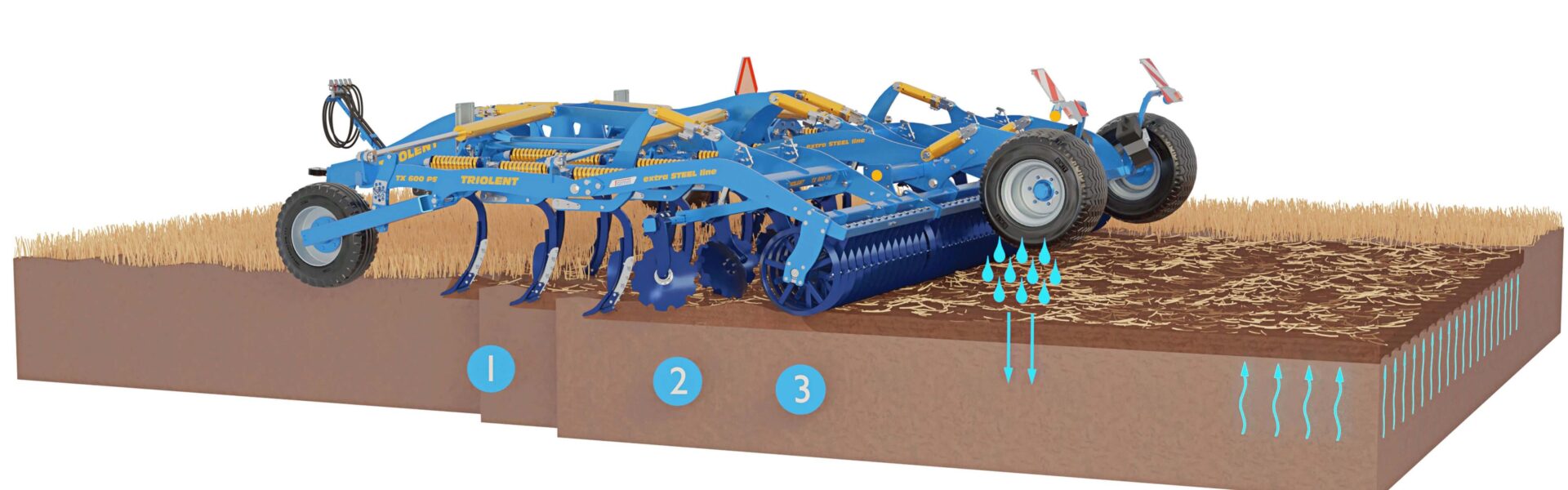

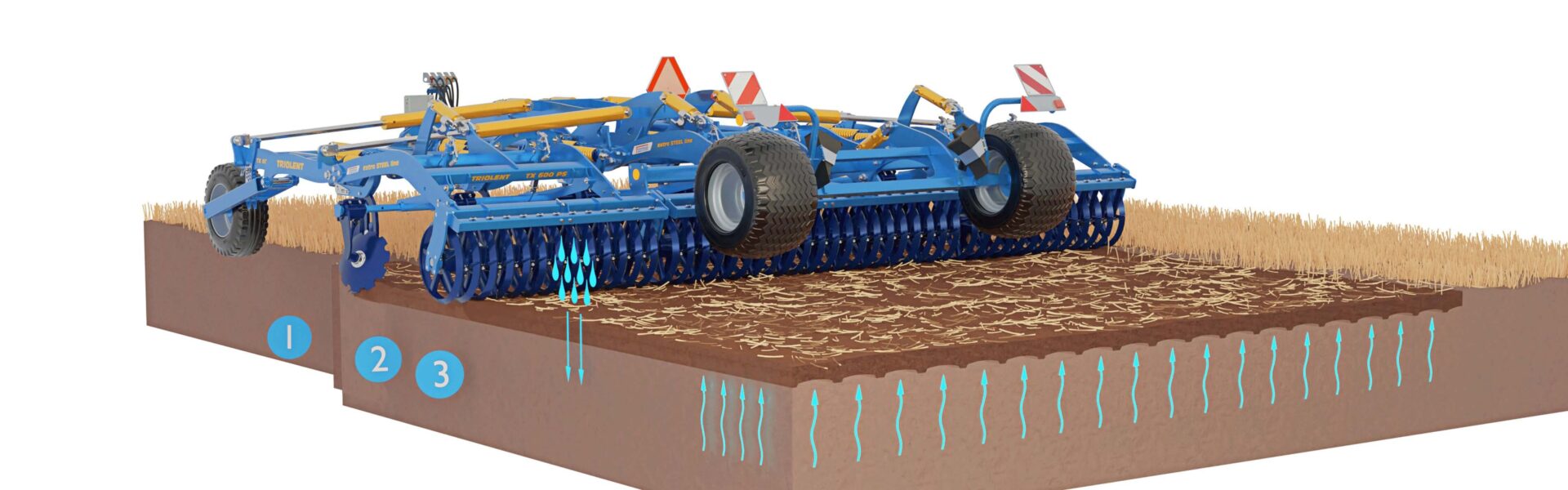

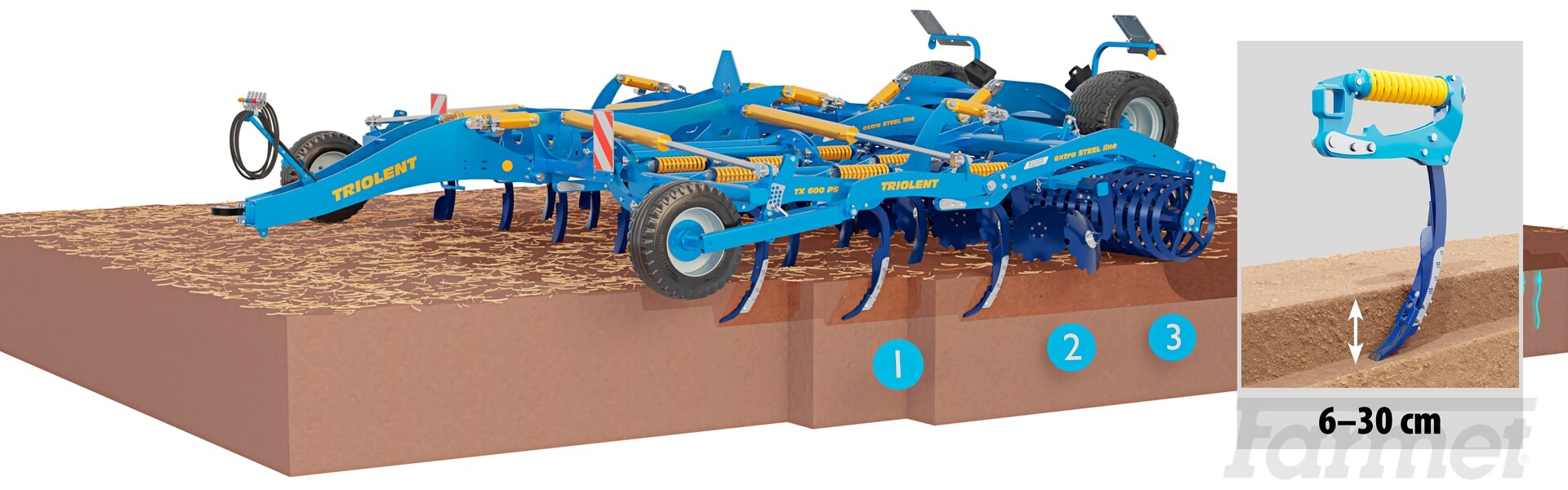

Triolent PS: soil cultivation up to 30 cm depth

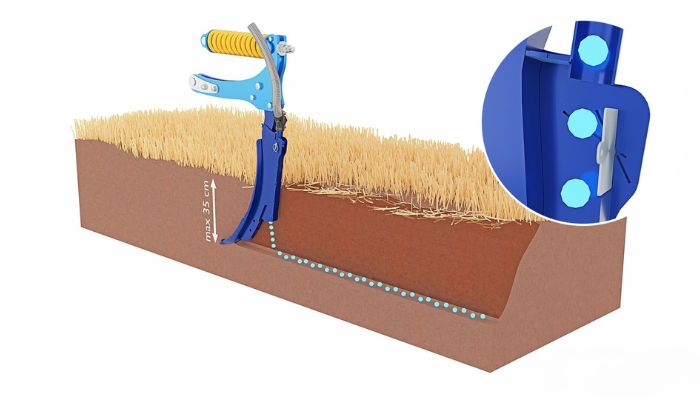

1. Soil loosening zone. Wide choice of working depths – from 6 to 35 cm. Tines with side wings for full-area stubble shaving are used when the soil is loosened from 6 to 20 cm. The tines arranged in three rows ensure very good soil loosening and intensive mixing of soil and plant residues.

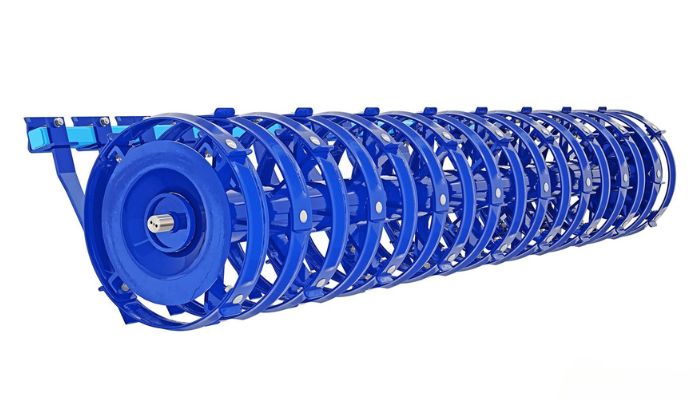

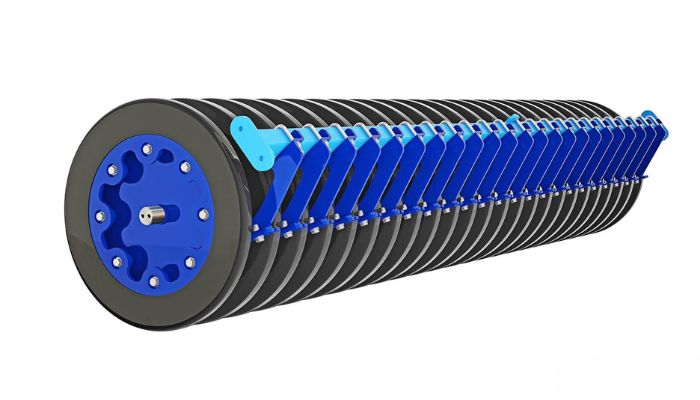

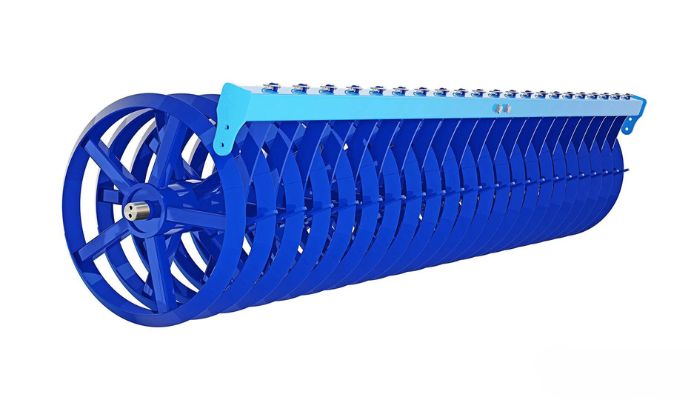

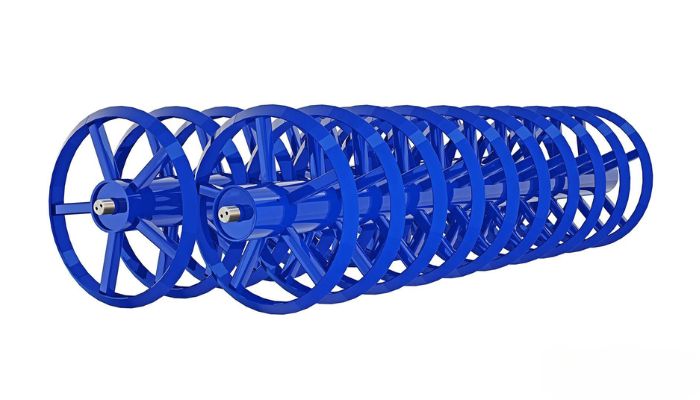

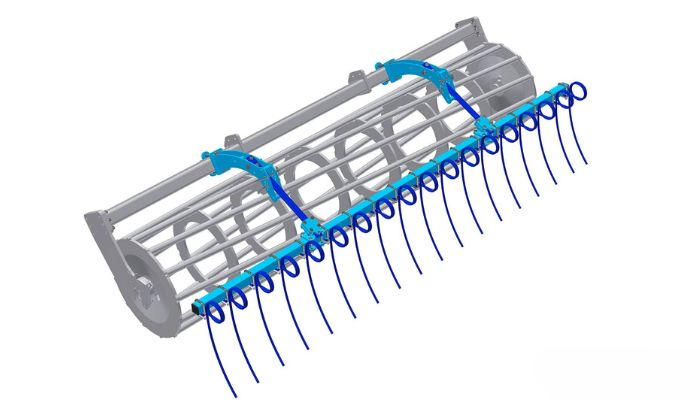

2. Surface leveling zone. Leveling discs also improve the incorporation of crop residues.

3. Clump breaking and soil compaction zone. Optimal soil compaction ensures good water penetration into the soil and moisture retention.

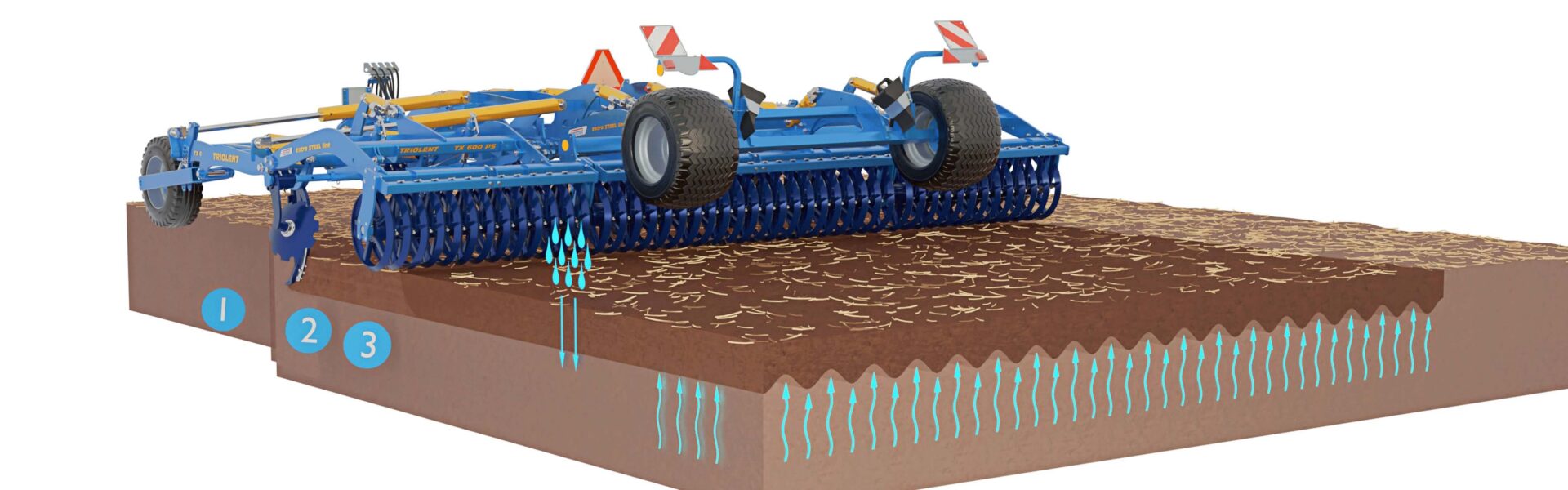

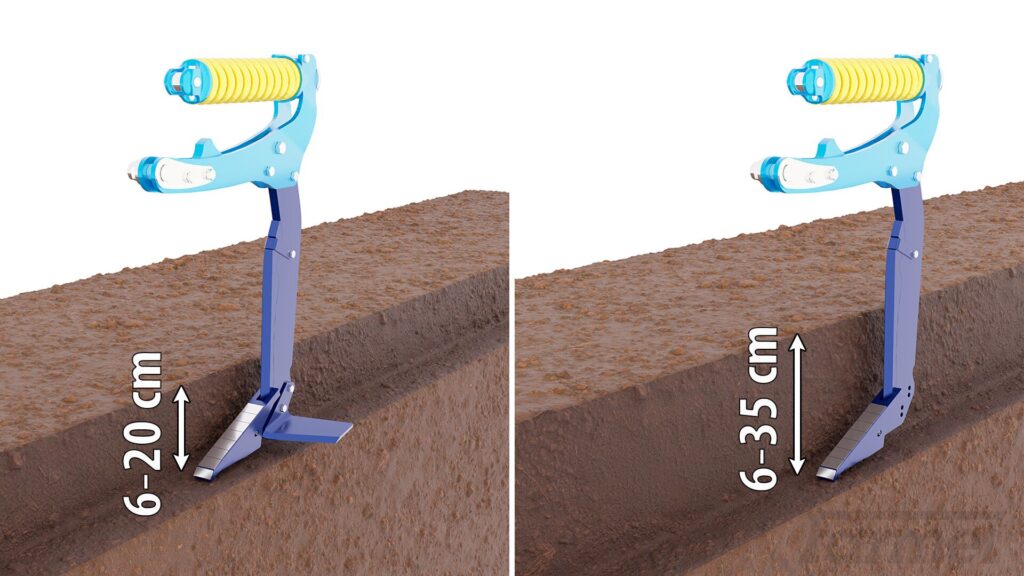

Fertilizer application options

Fertilizers are precisely applied below the soil surface - into the lower soil layer. This application ensures better availability of nutrients to plants and reduces their losses due to evaporation or leaching.

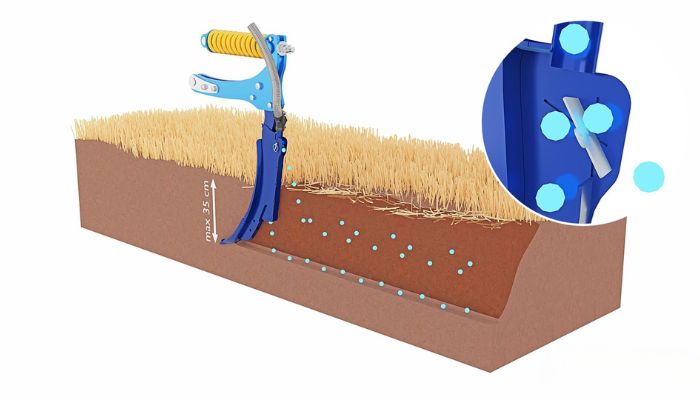

Fertilizer is distributed strategically: some is placed deep into the soil and some is placed shallowly, just below the surface, while ensuring even lateral distribution to maximize nutrient availability.

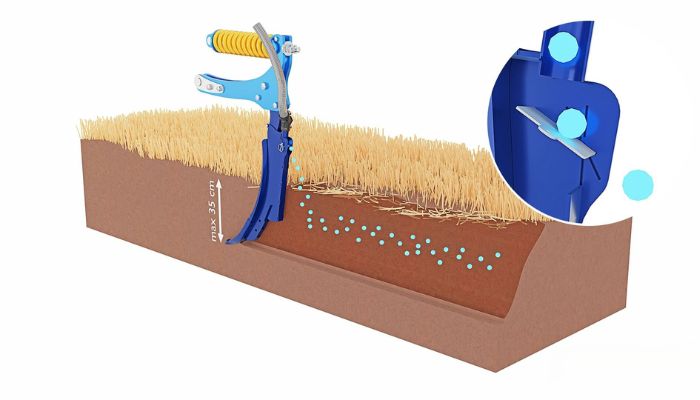

Fertilizer is precisely spread beneath the surface, while creating an even lateral distribution for efficient nutrient uptake.

High quality and efficient work

- High working speed – up to 12 km/h.

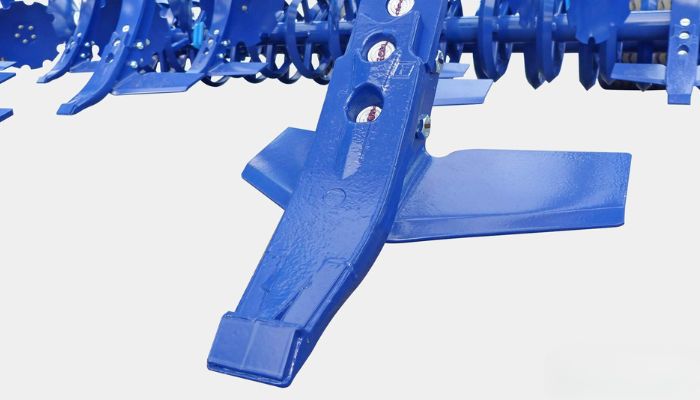

- Optimal tines shape ensures low resistance and excellent soil mixing.

- Excellent plant residues insertion.

- Curved upper part of the tines for soil flow control.

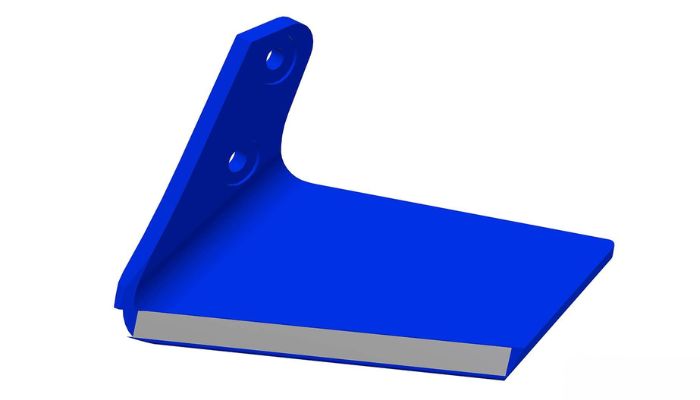

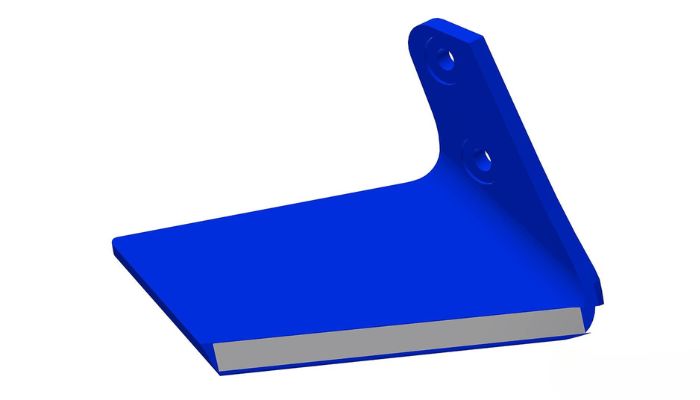

- Maintenance-free working parts with carbide plates.

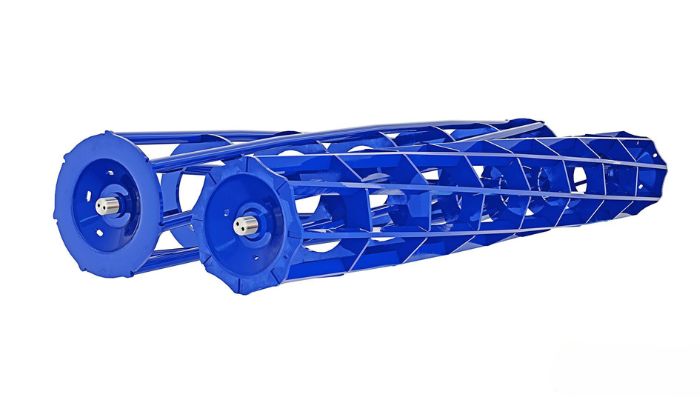

3. The rear roller compacts the soil, breaks up clods and smooths the surface. 3. The rear roller compacts the soil, breaks up clods and smooths the surface.

Wear-resistant metal Incorporation of crop residues Spring guards

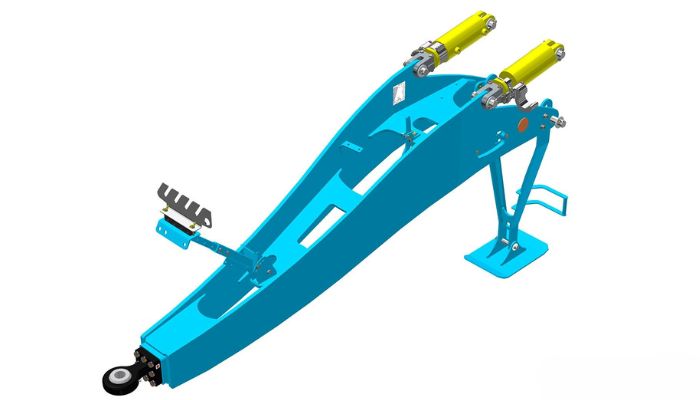

Triolent TX 400 P FIX pitchfork

Triolent TX 470 PS pitchfork

Sturdy construction

The tines are made of highly wear-resistant metal.

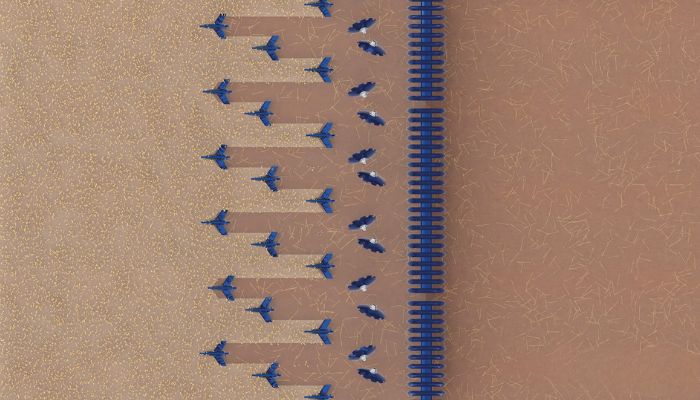

Full-surface stubble shaving after harvest with intensive mixing effect. Excellent incorporation of crop residues into the soil.

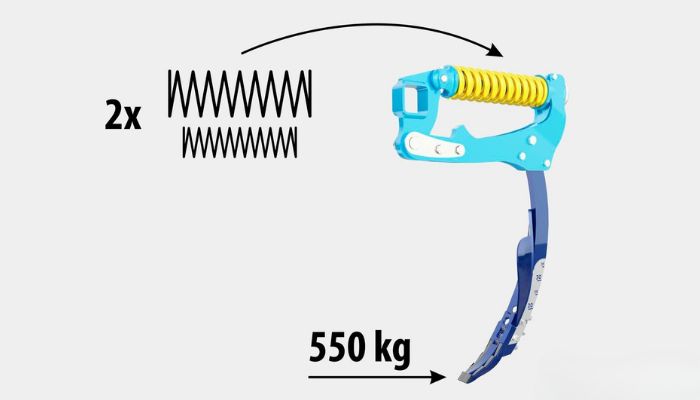

Robust and maintenance-free spring guards with a pressing force of 550 kg.Easy to use

A cleverly designed machine

Weight – 160 kg/m

Double ring DRR roller Weight – 200 kg/m

Weight – 220 kg/m

Weight – 175 kg/m

Weight – 180 kg/m

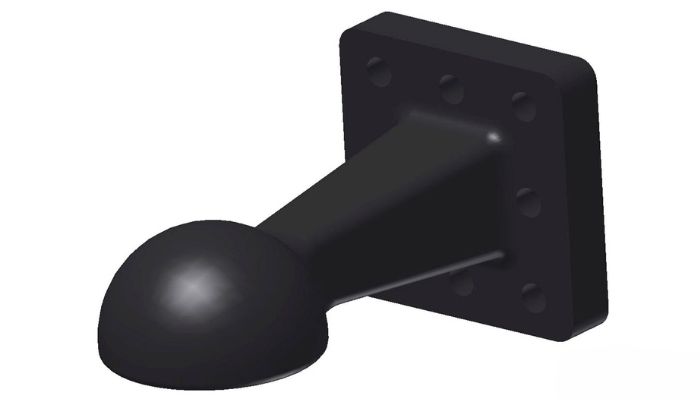

TPH Category 3 Eyelet for lower hitch Ø 40 mm, Ø 50 mm, Ø 70 mm K80 Ø 80 mm Pin set for category 4 three-point hitch (TPH)

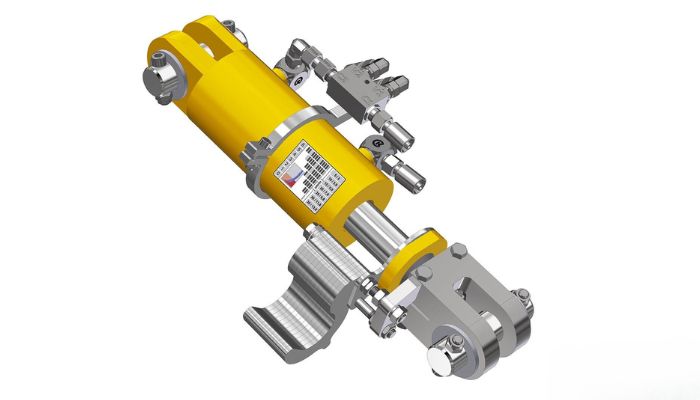

Hydraulic leveling discs Hydraulic working level adjustment Hydraulic towbar Micro Drill – small seed drill Shear bolt protection

Hydraulic brakes (trailer models only) Dual circuit 1-line brakes for trailed models only Rear harrows behind the rollerRollers

Diameter – 540/540 mm

Weight – 195 kg/m

Features Double DR roller Ring roller RR Double ring DRR roller LTX roller SDR disc roller V-shaped VR roller Double DVR roller

Crushing ●●●○ ●●●○ ●●●○ ●●○○ ●●●○ ●●●○ ●●●○

Compaction ●●●○ ●●●● ●●●● ●●●● ●●●● ●●●● ●●●●

Depth support ●●●● ●●●● ●●●● ●●●● ●●●● ●●●● ●●●●

Resistance to clogging ●●●○ ●●●● ●●●● ●●●○ ●●●○ ●●●● ●●●●

Suitability for rocky soils ●●●○ ●●●○ ●●●○ ●●●○ ●●●○ ●●●○ ●●●○

Suitability for wet soils ●●○○ ●●●● ●●●● ●●●● ●●●● ●●●● ●●●●

Suitability for heavy soils ●●●● ●●●● ●●●● ●●●● ●●●● ●●●● ●●●●

Suitability for medium soils ●●●● ●●●● ●●●● ●●●● ●●●● ●●●● ●●●●

Suitability for light soils ●●●● ●●●● ●●●● ●●●○ ●●●○ ●●●● ●●●●

Working tools

Chisel hardness: up to 55 HRC

Widia plate strength: Up to 92 HRA

Service life: +200-500 %

Chisel hardness: up to 55 HRC

Widia plate strength: Up to 92 HRA

Service life: +150-400 %

Chisel thickness: 15 m

Chisel thickness: 25 mm

Chisel strength: up to 55 HRC

Carbide plate strength: Up to 92 HRA

Usage time: +100-200 %

Fuel consumption: -10 %

Chisel thickness: 20 mm

Chisel strength: up to 55 HRC

Carbide plate strength: Up to 92 HRA

Fuel consumption: -10 %Towing

Other optional equipment

Not suitable for rocky soils

| TX 300 P | TX 400 P FIX | TX 470 PS | TX 600 PS | TX 800 PS | TX 1050 PS | |

|---|---|---|---|---|---|---|

| Type | trailed | trailed | trailed | trailed | trailed | trailed |

| Working width, mm | 3 000 | 4 000 | 4 700 | 6 200 | 7 900 | 10,500 |

| Transport width, mm | 3 000 | 4 000 | 3 000 | 3 000 | 3 000 | 3 000 |

| Transport height, mm | 1 400 | 1 400 | 3 000 | 3 300 | 4 000 | 4 000 |

| Total length, mm | 7 495 | 7 495 | 7 495 | 7 495 | 7 495 | 7 495 |

| Working depth, mm | 60–300 | 60–300 | 60–300 | 60–300 | 60–300 | 60–300 |

| Tines, pcs. | 10 | 14 | 16 | 19 | 25 | 31 |

| Distance between tines, mm | 300 | 285 | 294 | 326 | 316 | 339 |

| Rows of tines, pcs. | 3 | 3 | 3 | 3 | 3 | 3 |

| Distance between rows, mm | 780 | 780 | 780 | 780 | 780 | 780 |

| Fork pressure force, kg | 450 / 550 | 450 / 550 | 450 / 550 | 450 / 550 | 450 / 550 | 450 / 550 |

| Frame clearance, mm | 880 | 880 | 880 | 880 | 880 | 600 |

| Diameter of leveling discs, mm | 460 | 460 | 460 | 460 | 460 | 400 |

| Productivity, ha/hour | 2.4 – 3.6 | 3.2 – 4.8 | 3.8 – 5.6 | 4.8 – 7.2 | 6.4 – 9.6 | 8.4 – 12.6 |

| Tractor power, kW/HP | 110–165 150–225 | 125–190 170–255 | 150–220 200–300 | 245–370 330–500 | 295–440 400–600 | 370–550 500–750 |

| Working speed, km/h | 8–12 | 8–12 | 8–12 | 8–12 | 8–12 | 8–12 |

| Maximum working slope, ° | 6 | 6 | 6 | 6 | 6 | 6 |

| Tire measurements - for transportation | 19.0/45-17 | 19.0/45-17 | 19.0/45-17 | 19.0/45-17 | 19.0/45-17 | 550/45-22,5 |

| Brakes | air / 2 circuits | air / 2 circuits | air / 2 circuits | air / 2 circuits | air / 2 circuits | air / 2 circuits |

| Required pressure, kPa | 8,5 | 8,5 | 8,5 | 8,5 | 8,5 | 8,5 |

| Hydraulic connections/ pressure, bar | 2 / 200 | 2 / 200 | 3 / 200 | 3 / 200 | 3 / 200 | 3 / 200 |

| Number/type of hydraulic connection pairs | 4 / ISO 12.5 | 4 / ISO 12.5 | 6 / ISO 12.5 | 6 / ISO 12.5 | 6 / ISO 12.5 | 6 / ISO 12.5 |

| Tractor hitch | TPH categories 3 and 4; lower suspension K80; eyelet Ø 40, 50, 70 mm | TPH categories 3 and 4; lower suspension K80; eyelet Ø 40, 50, 70 mm | TPH categories 3 and 4; lower suspension K80; eyelet Ø 40, 50, 70 mm | TPH categories 3 and 4; lower suspension K80; eyelet Ø 40, 50, 70 mm | TPH categories 3 and 4; lower suspension K80; eyelet Ø 40, 50, 70 mm | TPH categories 3 and 4; lower suspension K80; eyelet Ø 40, 50, 70 mm |

| Weight, kg | 3 750 | 4 260 | 4 620 | 6 750 | 7 550 | 11 800 |

FARMETH – the largest manufacturer of agricultural machinery for tillage and sowing in the Czech Republic. The company, founded in 1992, is growing rapidly and devotes much attention and investment to the development of new technologies.

FARMETH agricultural equipment manufactured by this manufacturer must meet the strictest standards of work quality, reliability and durability. All equipment of this manufacturer 36 months warranty provided.

Products and technologies are developed in close collaboration with customers, research institutes and universities. FARMETH The products feature unique technological solutions, some of which are patented. The company seeks not only to improve product quality and create added value, but also to improve production technologies, productivity, and improve occupational safety and environmental protection.

FARMETH The brand is focused on high-quality products and high value. Major investments in modern production management ensure further quality improvement and more efficient production. The goal is to increase the added value of products and strengthen their competitiveness in all markets.

You can rent this equipment!

We offer the possibility of this technique rent for a day, a week or any other time you want. For rental conditions or other land cultivation, sowing, fodder preparation, and fertilization equipment, please contact our technical department.