Trailed disc harrows for scythes up to 18 cm with intensive mixing

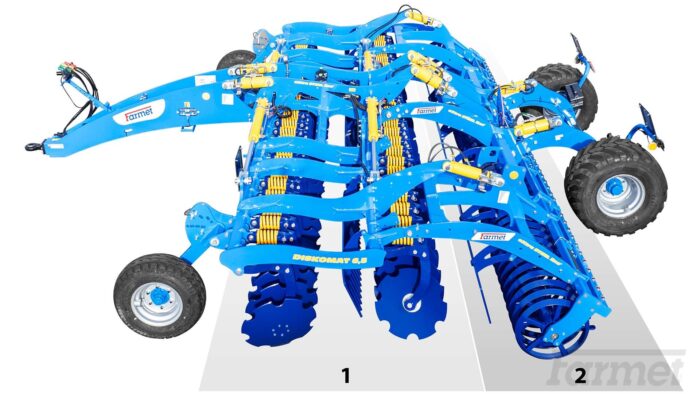

Trailed disc harrow Diskomat PS widely applicable in different stages of land cultivation

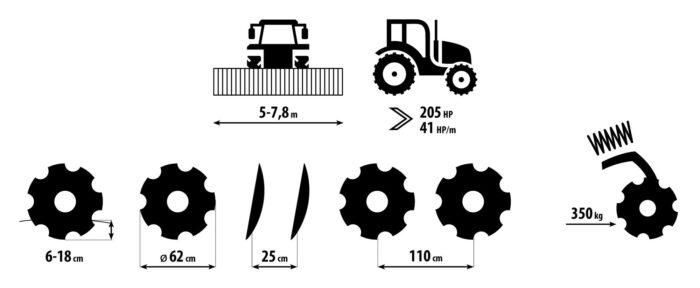

The massive 62 cm diameter discs make it ideal for shaving crop residues, especially corn, while the working depth of up to 18 cm ensures deep cultivation and intensive mixing.

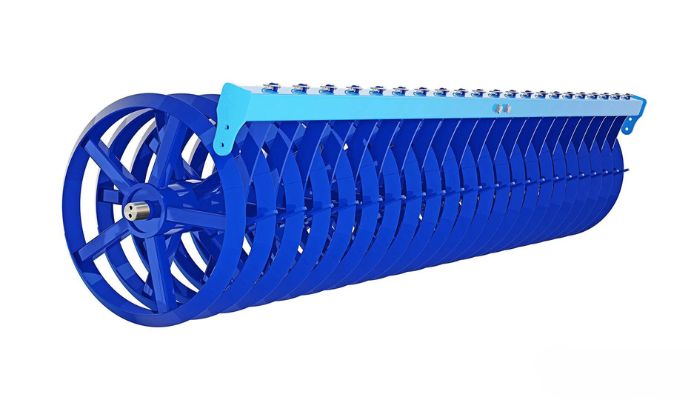

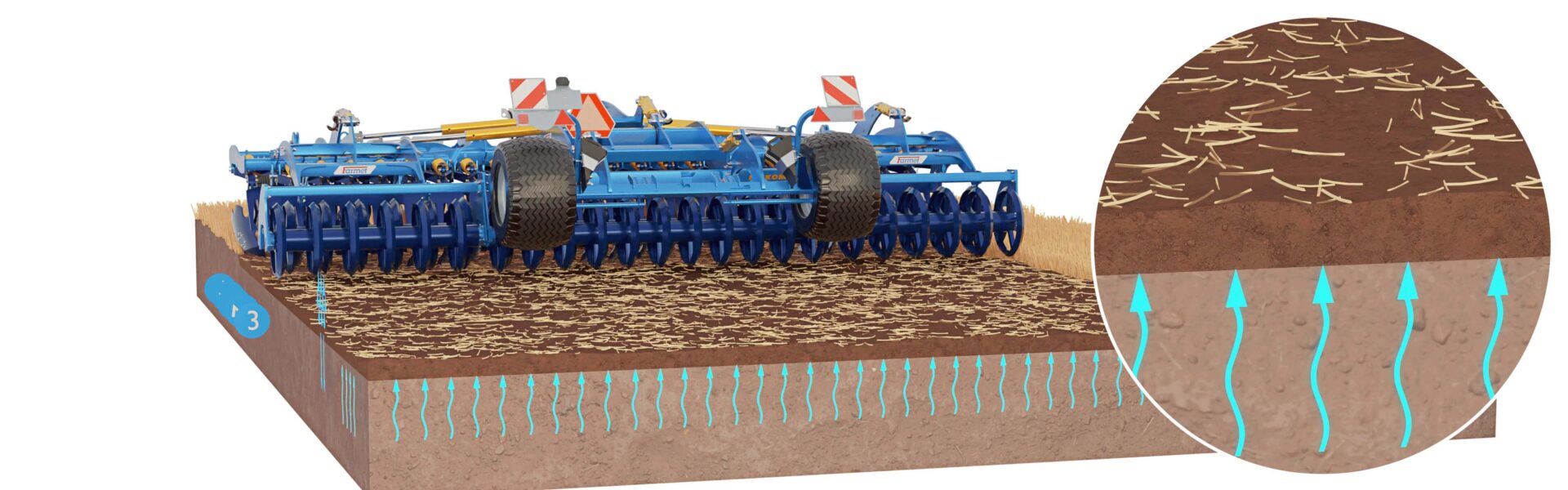

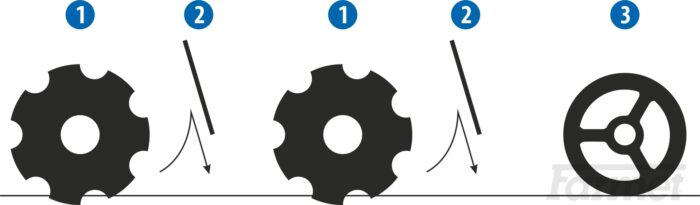

1. Full-area shaving zone. The two-row aggressive geometry disc section ensures perfect shaving over the full area at a depth of 6-18 cm with intensive mixing of plant residues. The disc section also distributes plant residues well over the entire working area.

2. Deflectors behind the discs increase soil compaction and incorporation of crop residues.

3. Clump breaking and soil compaction zone. Optimal soil compaction ensures good water infiltration and soil moisture retention.

High productivity and high quality of work

- High working speed – up to 15 km/h.

- High frame clearance – The scythe does not clog.

- Optimal disc inclination – great shave all over.

- Cut discs easily penetrates the soil and mixes it intensively.

- Maintenance-free spring disc protection – optimal working angle of the discs.

- Precise depth support with optimal soil compaction.

- Suitable for both for stubble cultivation up to 18 cm depth, as well as for other soil preparation work.

- Perfectly levels the soil, therefore widely used for pre-sowing soil cultivationwhen needed very good field leveling and quality cultivation.

1. 620 mm diameter discs arranged in two rows. Working depth 6–18 cm. Behind each row of discs there is a deflector against which the flying clods hit.

A big advantage of this cultivator's design is its good leveling effect on the ground surface, which makes the disc cultivator perfect for for pre-sowing soil preparation, where the most important requirements are even surface leveling and quality work result.

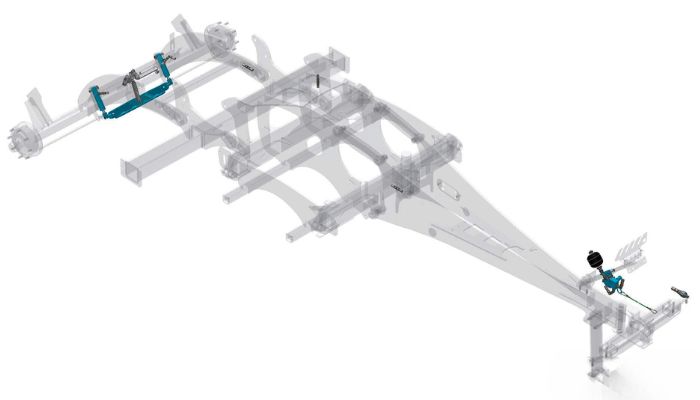

The Diskomat disc harrow stands out unique overall structural and design solution, as well as the implementation of individual technical units and the application of special material technologies. Such a solution ensures very compact dimensions (especially important when driving on public roads), very light weight and its optimal distribution on the working part. In addition, the machine is characterized by very low maintenance requirementsThe design complies with safety requirements and public traffic regulations required for operation on public roads.

Great attention is paid to the overall design and ergonomics of the machine. All control units are easily accessible to the operator and meet strict safety requirements. Most of the control elements are hydraulically operated and can be conveniently adjustable directly from the tractor cabThe mower is characterized by extremely low maintenance requirements. Compared to other similar devices on the market, the number of lubrication points and the frequency of lubrication are significantly reduced – Most components require absolutely no maintenance throughout the entire service life of the machine.

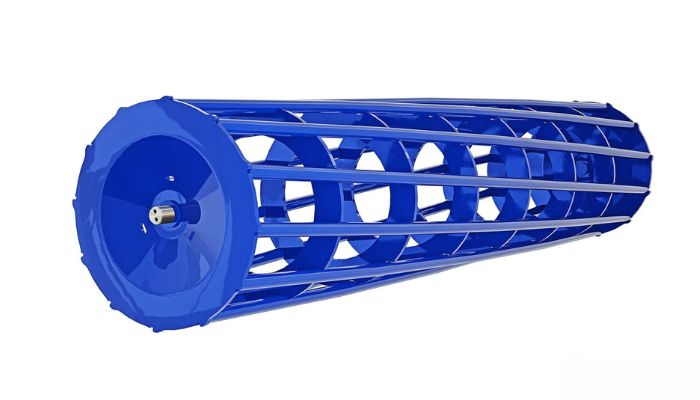

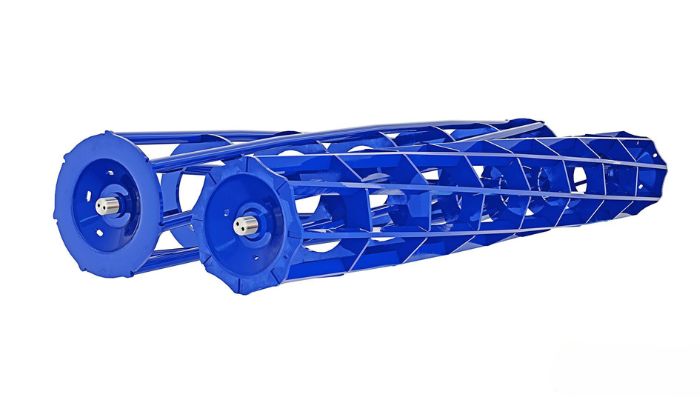

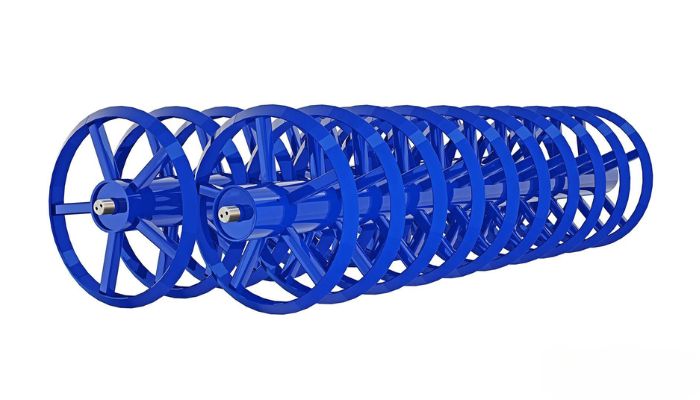

Depending on soil conditions, several different types of rear rollers to choose from. The integrated transport axle with braked wheels is part of the double rubber roller. This axle arrangement ensures a favorable position of the disc harrow during work and maximum pressure on the individual disc rows.

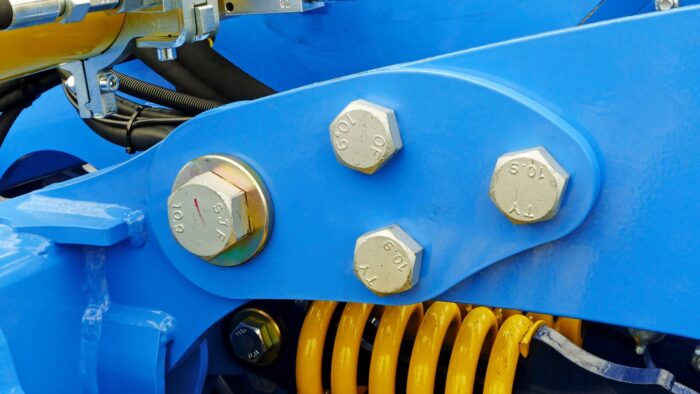

High quality replaceable bushings

Working depth adjustment Height-adjustable deflector

Micro Drill for sowing small seedsDiskomat 6.5 PS W

2. The clods are broken up by the rear roller.One of the main advantages of the design is effective surface leveling after tillage.

Compact dimensions, light weight

Low maintenance requirements

Choice of several rear roller types

This is essential to ensure reliable operation of the machine even in difficult soil conditions and at high operating speeds.Sturdy construction

The working units are mounted using replaceable high-quality bushings, which ensure a longer service life of the unit.Easy to use

Simple adjustment of the working depth according to the table - set by the gaskets (rings) in the piston rods of the roller cylinders.

The height-adjustable right side deflector ensures optimal distribution of the processed soil.A cleverly designed machine

The advanced design of the machine allows for the installation of Micro Drill seeding equipment for sowing cover crops or direct incorporation of grass.

Tubular TRS roller

Weight – 195 kg/m

Weight – 220 kg/m

Weight – 175 kg/m

Weight – 180 kg/m

Disc Ø 620 mm

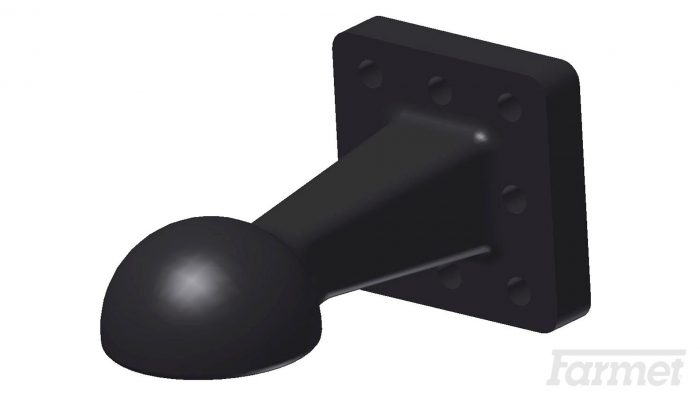

TPH Category 3 Eyelet for lower hitch Ø 40 mm, Ø 50 mm, Ø 70 mm K80 Ø 80 mm Pin set for TPH category 4

Hydraulic brakes Micro Drill small seed drill 2 lines 1 circuit air brakes Support wheelsRollers

Diameter – 600 mm

Weight – 100 kg/m

Tubular TRS roller Double DR roller Ring roller RR Double ring DRR roller Disc roller SDR V-shaped VR roller Double V-shaped DVR roller

Crushing ●●○○ ●●●○ ●●●○ ●●●○ ●●●○ ●●●○ ●●●○

Compaction ●●●○ ●●●○ ●●●● ●●●● ●●●● ●●●● ●●●●

Depth support ●●●○ ●●●● ●●●● ●●●● ●●●● ●●●● ●●●●

Resistance to clogging ●○○○ ●●●○ ●●●● ●●●● ●●●○ ●●●● ●●●●

Suitability for rocky soils ●●●○ ●●●○ ●●●○ ●●●○ ●●●○ ●●●○ ●●●○

Suitability for wet soils ●○○○ ●●○○ ●●●● ●●●● ●●●● ●●●● ●●●●

Suitability for heavy soils ●●○○ ●●●● ●●●● ●●●● ●●●● ●●●● ●●●●

Suitability for medium soils ●●●○ ●●●● ●●●● ●●●● ●●●● ●●●● ●●●●

Suitability for light soils ●●●● ●●●● ●●●● ●●●● ●●●○ ●●●● ●●●●

Working tools

Towing

Other optional equipment

| Diskomat 5 PS | Diskomat 6 PS | Diskomat 6.5 PS W | Diskomat 8 PS | Diskomat 8.5 PS W | |

|---|---|---|---|---|---|

| Type | trailed | trailed | trailed | trailed | trailed |

| Working width, mm | 5 000 | 6 000 | 6 300 | 7 800 | 8 300 |

| Transport width, mm | 3 000 | 3 000 | 3 250 | 3 000 | 3 750 |

| Transport height, mm | 3 300 | 3 650 | 4 000 | 4 000 | 4 000 |

| Total length, mm | 6 600 | 6 600 | 6 600 | 6 600 | 7 250 |

| Working depth, mm | 60–180 | 60–180 | 60–180 | 60–180 | 60–180 |

| Number of discs – front row, pcs. | 20 | 24 | 25 | 30 | 33 |

| Number of discs – rear row, pcs. | 20 | 24 | 25 | 30 | 33 |

| Disc diameter, mm | 620 | 620 | 620 | 620 | 620 |

| Productivity, ha/hour | 5–7.5 | 6–9 | 6.3─9.5 | 8─12 | 8.5─13 |

| Tractor power, kW/HP | 150─220 205─300 | 180─260 245─355 | 190─270 260─370 | 240─300 325─410 | 260─330 350─450 |

| Working speed, km/h | 10–15 | 10–15 | 10–15 | 10–15 | 10–15 |

| Maximum working slope, ° | 6 | 6 | 6 | 6 | 6 |

| Tire measurements - for transportation | 19.0/45-17 10.0/75-15,3 | 19.0/45-17 10.0/75-15,3 | 520/50 R17 | 19.0/45-17 10.0/75-15,3 | 520/50 R17 |

| Brakes | air / 2 circuits | air / 2 circuits | air / 2 circuits | air / 2 circuits | air / 2 circuits |

| Required pressure, kPa | 8,5 | 8,5 | 8,5 | 8,5 | 8,5 |

| Hydraulic connections/pressure, bar | 3 / 200 2 / 200 | 3 / 200 2 / 200 | 3 / 200 2 / 200 | 3 / 200 2 / 200 | 3 (4) / 200 2 / 200 |

| Number/type of hydraulic connection pairs | 6 / ISO 12.5 4 / ISO 12.5 | 6 / ISO 12.5 4 / ISO 12.5 | 6 / ISO 12.5 4 / ISO 12.5 | 6 / ISO 12.5 4 / ISO 12.5 | 6 / ISO 12.5 4 / ISO 12.5 |

| Tractor hitch | TBZ Category 3 | TBZ Category 3 | TBZ Category 3 | TBZ Category 3 | TBZ Category 3 |

| Weight, kg | 6 200 | 6 950 | 7 850 | 8 660 | 10 000 |

FARMETH – the largest manufacturer of agricultural machinery for tillage and sowing in the Czech Republic. The company, founded in 1992, is growing rapidly and devotes much attention and investment to the development of new technologies.

FARMETH agricultural equipment manufactured by this manufacturer must meet the strictest standards of work quality, reliability and durability. All equipment of this manufacturer 36 months warranty provided.

Products and technologies are developed in close collaboration with customers, research institutes and universities. FARMETH The products feature unique technological solutions, some of which are patented. The company seeks not only to improve product quality and create added value, but also to improve production technologies, productivity, and improve occupational safety and environmental protection.

FARMETH The brand is focused on high-quality products and high value. Major investments in modern production management ensure further quality improvement and more efficient production. The goal is to increase the added value of products and strengthen their competitiveness in all markets.

You can rent this equipment!

We offer the possibility of this technique rent for a day, a week or any other time you want. For rental conditions or other land cultivation, sowing, fodder preparation, and fertilization equipment, please contact our technical department.