The system allows you to continuously adjust and maintain the correct tire pressure for various tasks, speeds, and field and road conditions.

PTG central tire pressure regulation system – for tractors and self-propelled machines

This system is suitable for tractors, self-propelled shredders, sprayers, combines, slurry tankers and trailers.

Various systems are offered – from AIRBOX/mobil, designed for tire inflation for each axle of a stationary vehicle, to the fully automated RDS pressure regulation system for a moving vehicle.

Today, the tractor is a tool whose capabilities have grown significantly over the past few years. At speeds of up to 60 km/h, it can be used to move quickly from field to field and for road transport; all the while, the high rear axle loads often need to be supported by the tyres.

Advantages of a central tire pressure regulation system:

- Less tire wear and lower fuel consumption when driving on the road;

- Better wheel grip when working in the fields;

- Reduced soil compaction, rutting and erosion;

- Ability to work in more difficult outdoor conditions, especially in wetter areas of the fields.

The tire is the connection between the machine and the ground (field/road) and must perform multifunctional tasks:

- It should be hard on the road and roll well, but at the same time wear out little.

- In the field, traction with the soil must be smooth, even and without slipping.

Two requirements that essentially contradict each other!

Requirement 1:

The road should be firm and roll well, but at the same time wear little, which is only possible with high tire pressure.

Requirement 2:

In the field, traction must be smooth, even and non-slip, which is only possible with low tire pressure.

Advantages/Benefits of High Tire Pressure on the Road

On the road with high tire pressure:

Significantly smaller tire footprint.

Note: The tire walls are stabilized.

- High load when driving at high speed.

- Increased directional and driving stability.

- Greater safety in traffic by avoiding driving with too little air in the tires.

- 15% and above have lower fuel consumption due to rolling resistance.

- Less chance of tire damage.

Outdoors with low tire pressure:

Significantly larger tire footprint.

Note: The tire becomes only minimally wider, but significantly longer.

- Reduced pressure on the soil.

- Reduced tire rut depth.

- Reduced chance of slipping

- No/less damaging soil compaction.

- Increased yield.

- Significantly better tire grip.

Correct tire pressure outdoors

- Fuel consumption in the field (reduced by 10-15%).

- Wheel slip is reduced by 20%.

- Less dependence on weather conditions in case of urgent field work conditions.

- Extended seasonal working hours.

- More effective self-cleaning of the tire tread due to more flexible tires.

- Active protection of operator health by reducing body vibration.

- Less chance of tire damage.

Types of tire pressure regulation systems

Adjusting tire pressure while the tractor is stationary:

• AIR BOOSTER

Manual pressure adjustment, adjustable for each wheel separately.

• AIRBOX/mobile

Semi-automatic, it automatically adjusts the pressure in all tires connected to the system to the selected value.

Adjusting tire pressure while the tractor is moving:

• RDS/AS 2L – for tractor rear axle

Radial swivel joint on the inside of the tire.

• AIRBOS/drive 2L and AIRBOX/drive 1 L – for tractors and trailers

Swivel joint on the outside of the tire, air is directed over the fender

• RDS/GW 2L and RDS/GW 1L – for trailers

Air is directed centrally through the axle. Ideal for all non-driven axles.

• RDS/portal 2L - for combines

Air is supplied centrally through the axis.

1-circuit pneumatic control for tractors AIRBOX/drive 1 circuit technology is controlled simply and conveniently using a switch control panel in the cabin. 1-circuit pneumatic control for slurry tankers and towed vehicles The operator sets the desired pressure for road and field on a pressure gauge console located outside the vehicle. The system saves these settings, which can of course be changed at any time.

Using the control panel in the cab, the operator simply selects the desired mode (road or field); the controller changes the pressure in all tires to a preset value, and then turns off (only for dual-circuit machines). ISOBUS 2-circuit control for tractors The tire inflation system is controlled using an ISOBUS-compatible vehicle control terminal, as the PTG system is connected to the vehicle via ISOBUS. The tire inflation system offers the following screens, which can be selected from the terminal menu screen:

Digital 2-circuit control for tractors With digital control, the operator has universal control to simultaneously control the tire inflation system of both the towing vehicle and the trailer. The preset tire pressure is displayed at the touch of a button.System management

The operator pre-selects the desired field or road pressure (continuous adjustment). Using a switch, the operator can switch between two pre-selected pressure ranges with one movement. The pressure is immediately adjusted in all tires connected to the system to the pre-selected value. The target and actual values are continuously displayed on the corresponding pressure gauges

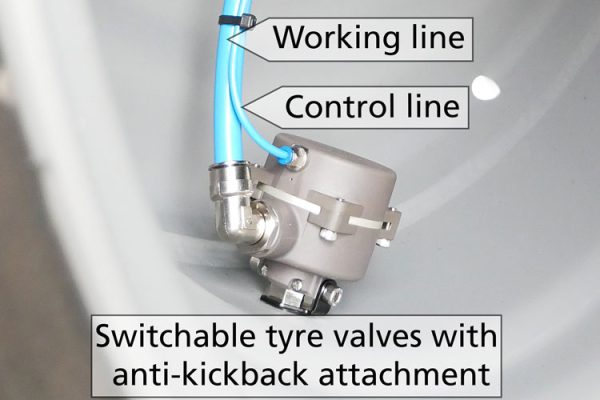

When a control cycle is activated (e.g. the rear axle of a tractor), the system is activated and regulates the tire pressure to a preset value. When the target pressure is reached, the tire valves automatically close, the system reduces the pressure and switches off.

The system can also be turned off at any time, even during a control cycle, by pressing a button.

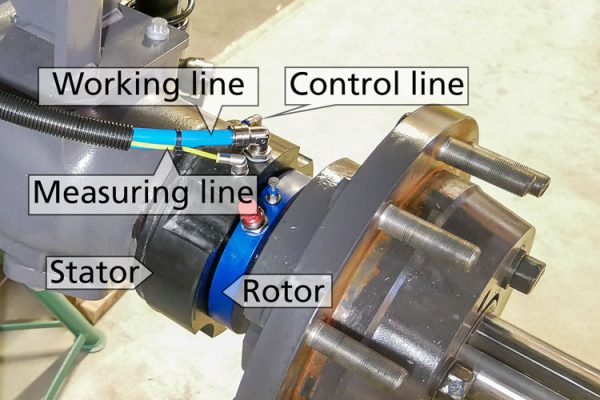

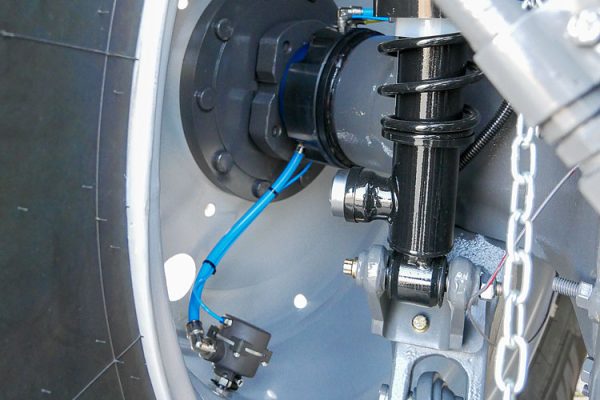

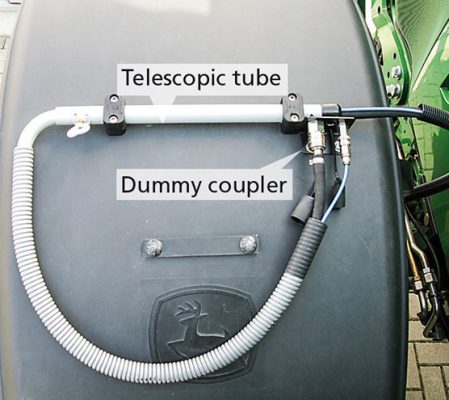

RDS /radial 2L for tractor rear axle RDS/radial – a great system for convenient tire inflation adjustment on the move. Suitable for all tractor axles. The stator is bolted to the axle housing, aligned with the axle centerline, the rotor is in line with the stator on the axle shaft and secured with a wrench. Both the working line and the control line rotate synchronously with the rotor and are led to the tire valve. The patented dual-circuit principle ensures that after each pressure change, the tire valves are closed and the pressure in all system components is reduced, thus protecting it from unnecessary wear. This technology also ensures that the tire will not lose air even in the event of a leak in the regulation system or a broken line, thus ensuring maximum safety. Adjustable tire pressure for field and road work is selected at the touch of a button for all tires connected to the system. Once the system is activated, all selected tire pressure values in each tire are automatically adjusted, and when finished, the system turns itself off. The system can be turned off at any time by pressing a button. RDS/radial 2L for rear axle and AIRBOXdrive for front axle For all types of tractor axles The stator is bolted to the axle housing, aligned with the axle centerline, the rotor is in line with the stator on the axle shaft and secured with a wrench. Both the working line and the control line rotate synchronously with the rotor and are led to the tire valve. The air lines are routed through the wing to the center of the wheel using a telescopic tube, allowing the distance to the side of the rotating wheel to be individually adjusted. AIRBOX / drive 2L is connected to the pneumatic brake system via a safety valve, so the 6.5 bar pressure in the tractor reservoir will always be constant. The central tire pressure control system is operated simply and conveniently with the control panel or via the tractor's ISOBUS terminal. The tire pressure for field or road work is selected for all tires connected to the system with just one push of a button. When the system is turned on, all selected tire pressure values in each tire are automatically adjusted, and the system switches off itself after work is finished.2-circuit systems for tire pressure regulation on the move

Essentially, the system works by transferring air from a stationary component (the stator) to a rotating component (the rotor). To make this process work, the stator is fitted with pressure-resistant rotary seals, which together with the rotor form annular channels through which air pressure flows, whether the tractor is stationary or moving.

Air is supplied from the vehicle's own compressor and the brake system's air reservoir. The brake priority valve, also known as the overflow valve, ensures that the pressure in the air brake reservoir does not drop below 6.5 bar (94 psi) so that the brakes have priority over the tire inflation system.

A great system for convenient tire inflation adjustment on the move.

Essentially, the system works by transferring air from a stationary component (the stator) to a rotating component (the rotor). To make this process work, the stator is fitted with pressure-resistant rotary seals which, together with the rotor, form annular channels through which air pressure flows, whether the tractor is stationary or moving.

On the front axle, the rotary joint is mounted on the wheel studs concentrically with the center axle. The rotor and stator are arranged in one line. Both the working line and the control line rotate synchronously with the rotor and are led to the tire valve.

Both the main air supply and control lines are connected to the swivels using quick-release couplings so that they can be easily removed when not in use and placed in specially prepared locations on the wings.

Pressure is only created in the entire system, both on the front and rear axles, at the moment of control (inflation or deflation). The patented dual-circuit principle ensures that after each pressure change, the tire valves are closed and the pressure in all system components is reduced, thus protecting it from unnecessary wear. This technology also ensures that the tire will not lose air even in the event of a leak in the regulation system or a broken line, thus ensuring maximum safety.

The German company PTG has been manufacturing and selling central tire pressure regulation systems (CTIS) for over 30 years. They are one of the leaders in this product segment. The company's main export regions are Western Europe and North America.

PTG has been part of the Michelin group of companies since 2018. Central tire pressure regulation systems are suitable not only for tractors, but also for self-propelled shredders, sprayers, combines, and trailers.