36 – 44 m³ capacity models with 35 mm chip size and continuous flow system

Magnon 8 – large loading capacity in a compact design

The Magnon series of self-loading trailers is unsurpassed in terms of productivity and working efficiency. It premium class self-loading trailers, designed for maximum productivity and efficiency.

This model combines high performance, fine chopping and compact design - an ideal choice for those looking for powerful but maneuverable equipment.

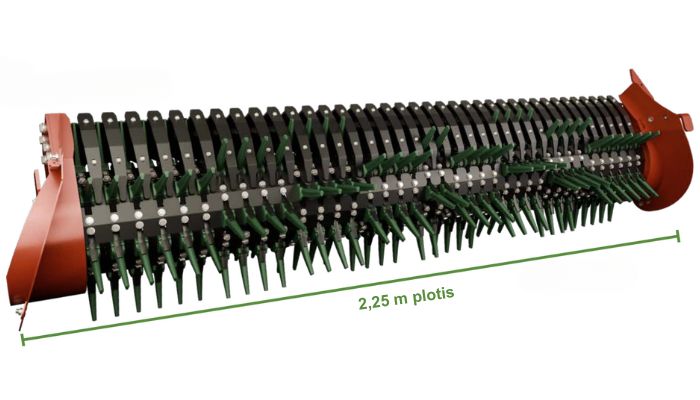

Trailer transportation system stands out for its high performanceand the unique Flex-Load pick-up with a width of 2.25 m ensures excellent feed intake and works ideally together with the proven CFS Continuous Flow System. The integrated rotor reliably transports even large volumes of rolls through the cutting system into the loading area.

Main features:

- 3 models with 36 m³, 40 m³ and 44 m³ loading capacity

- 35 mm cutting size – precise and uniform feed preparation

- Precise chopping with 48-knife Exact-Cut system

- CFS Verified continuous flow loading systema – for permanent work

- Flex-Load collector – high feed quality and low wear and tear

- Sturdy construction with hydraulically sliding front wall and compact dimensions

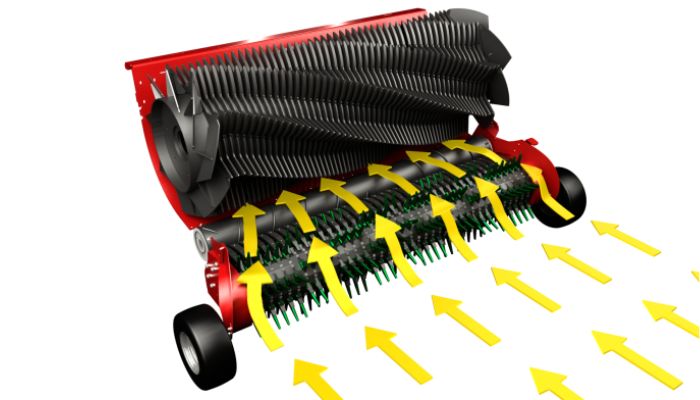

Exceptional Flex-Load collector – is the result of decades of experience in the production of silage trailers. Innovative plastic fingers ensure exceptional wear resistance. They are stiff enough to precisely lift the feed from the roller, but also flexible, so that adapt to the terrain This reduces mechanical wear, operating costs and operator workload – the ideal solution for efficient work every day.

Perfect feed flow is ensured by using the CFS Continuous Flow System with an integrated, overhead rotor, which not only distributes materials evenly across the entire width of the cargo area, but also shortens the loading path, reducing power requirements and allowing for maximum and uniform filling. This ensures faster loading with less energy.

The Exact-Cut cutting system ensures consistent and flawless chopping quality: 48 double-sided knives with individual protection allow for precise and even chopping 35 mm theoretical cutting size, and the central blade locking mechanism ensures quick and easy blade changes. Also, the automatic blade retraction mechanism guarantees high driving comfort, and the maintenance-free design helps reduce maintenance costs.

Sturdy steel structure ensures durability and resistance to intensive use, while the hydraulically opening front wall allows for quick and efficient unloading of the contents. Convenient access to the interior simplifies maintenance and cleaning, and the optimal filling level guarantees maximum volume utilizationSteel floors are highly resistant to wear and load. Different chassis options ensure optimal driving comfort and safety in all conditions. Tandem lever the chassis guarantees a reliable foundation, and hydraulic tandem The chassis increases stability and comfort at higher speeds. Hydraulic three-axle The chassis allows for greater load capacity and ensures even weight distribution. Passive steered axle reduces friction, protects the lawn and makes maneuvering easier. Mechanically and electronically controlled forced steering axle allows active control of movement even when driving in reverse, ensuring maximum maneuverability and stability.

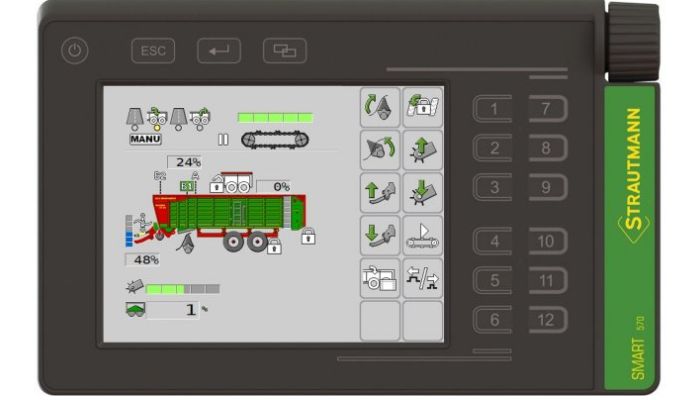

Convenient and intuitive trailer control is provided by standard ISOBUS control via the tractor terminal – a reliable and easy-to-understand interface, with the option of integrating the right-hand control terminal Smart 570 with a 5.7-inch colour display. Precise loading and unloading process management and safe driving on the road are combined with numerous automatic functions that ensure maximum ease of use and comfort.

Flexible loading – save time and effort

CFS Continuous Flow System with Integrated Rotor

Consistent and flawless chopping quality with Exact-Cut cutting system

Optimal surface adaptation

Robust construction and functionality for everyday use

Chassis – for comfort and safety in all conditions

Convenient control

Optional equipment – can be installed as needed. Protects feed during silage transport, preventing losses. Hydraulic control via ISOBUS terminal – convenient and fast. The central overlap ensures complete coverage of the transported mass.

Possibility to install a rear view camera and/or a cargo area camera. An available rear camera provides additional safety when driving on the road. Easier reversing maneuvering. The loading process is monitored using a cargo camera, ensuring maximum loading volume.

LED taillights with additional side marker lights. LED lighting strips for cargo area lighting. LED work lights – 2 rear and 2 additional lights behind the transmission.

Unique Flex-Load pickup

Flexible plastic fingers

New one-piece rotor

48 double-sided knives with individual protection

Rotor and cutting unit perfectly adapted for precise cutting

Sturdy body

Hydraulically sliding front wall

Overload protection strips

Sturdy back cover

Foldable mesh awning

Video camera systems

LED lighting

Hydraulic tandem chassis

10-470 and 11-470 equipment.Hydraulic three-axle chassis

Passive steered axle

Electro-hydraulic forced steering axle

Management

| Model | Magnon 8-370 | Magnon 8-410 | Magnon 8-450 |

|---|---|---|---|

| Length [m] | 9,25 | 9,90 | 10,53 |

| Height (without 90 mm riser) [m] | 3,90 | 3,90 | 3,90 |

| Cargo height [m] | 2,08 | 2,08 | 2,08 |

| Cargo area height (with 90 mm riser) | 2,17 | 2,17 | 2,17 |

| Width of the cargo area [m] | 2,25 | 2,25 | 2,25 |

| Length of cargo part [m] | 6,52 | 7,17 | 7,80 |

| Outer wheel width [m] | 2,81 | 2,81 | 2,81 |

| Net weight (without/with DO) [kg] | 10 200 / 10 700 | 10 600 / 11 100 | 11 200 / 11 700 |

| Permissible total weight – standard [kg] | 22 000 | 22 000 | 24 000 |

| Permissible total weight – optional [kg] | 24 000 | 24 000 | 31 000 |

| Minimum tractor power [kW/HP] | 110 / 150 | 125 / 170 | 140 / 190 |

| Loading capacity (average compaction) [m³] | 67 | 74 | 81 |

| Loading capacity according to DIN 11741 [m³] | 36 | 40 | 44 |

| Number of knives [pcs.] | 48 | 48 | 48 |

| Pick-up working width [m] | 2,25 | 2,25 | 2,25 |

| Theoretical chopping length [mm] | 35 | 35 | 35 |

| Transmission system | Rotor | Rotor | Rotor |

A family-run company based in northern GermanyB. Strautmann & Söhne GmbH u. co. KG"has been around for over 85 years.

STRAUTHMANN The factory has developed a wide range of products, especially well suited for livestock farms. The company can offer silage handling equipment for various purposes: silage buckets, silage cutters and silage block cutters for easy silage removal.

STRAUTHMANN Silage block and feed transport trailers have been ensuring fast and easy feed supply for several decades. We also manufacture trailed and self-propelled feed mixers - perfect for preparing physiologically ideal animal feed.

For optimal feed quality, STRAUTHMANN presents grass silage handling equipment. In order to maintain the best quality of feed, the grass loaded into the self-loading trailer is gently but optimally chopped. Customers can purchase tri-axle trailers and dump trucks as well as trailers for convenient feed transportation. Also, manure and universal shakers are available in various sizes. Thus, by creating a high-quality and diverse product offering, STRAUTHMANN the company becomes a competent partner for the farmer.