Suspended precision drill, suitable for tractors from 120 hp

A new generation of high quality drilling with SOLA Velox

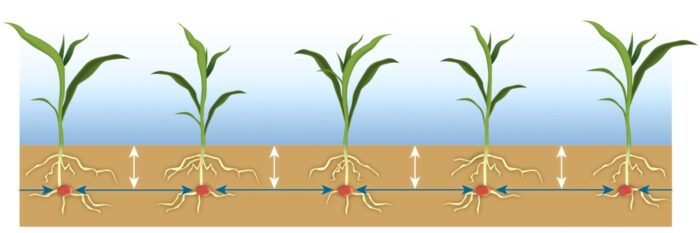

Designed to maximise yield potential by sowing with perfect seed separation and spacing, ensuring consistent placement depth and perfect seed-to-soil contact.

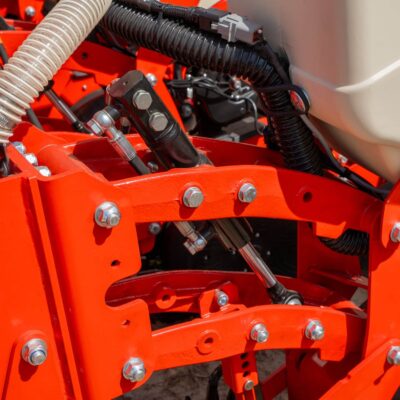

- Reinforced cast iron parallelogram suspension - for greater reliability and durability

- Hydraulic pressure system - up to 350 kg pressure on each line

- Long-lasting, maintenance-free parallelogram bushes

- Floating residue wipers - with optional side wheels

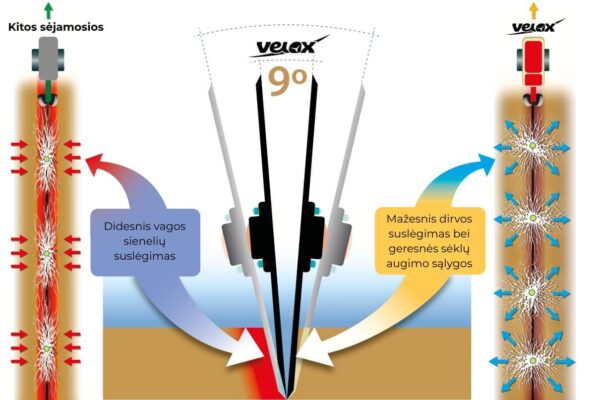

- 15" double discs with 9° angle

- Large capacities 70 l bunkers

- Moisture-resistant lids with locks

- Up to two optional micro granular hoppers

- Precision vacuum seed metering

- Electric seed metering drive system (ELEKTRA)

- Simple depth adjustment

- Reinforced protection for triple seal bearings

Highlights of the Velox

Hydraulic pressure system

VELOX row section pressure is maintained by hydraulic cylinders that provide a uniform force of up to 350 kg per row, allowing a pre-set drilling depth to be maintained regardless of changing field conditions.

Double disc design

The narrow angle of the twin discs combined with hydraulic pressure control guarantees a uniform insertion depth and optimum conditions for the development of each seed for the highest results.

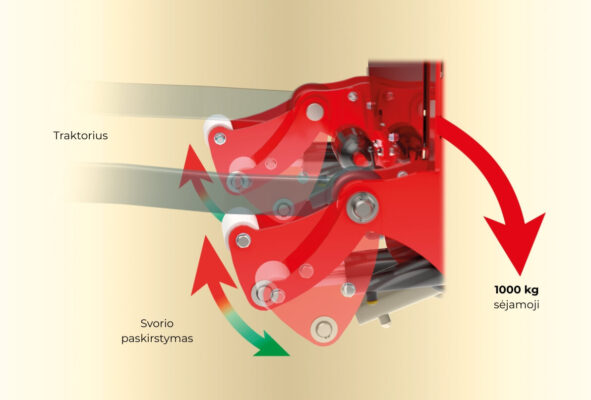

Adaptive weight distribution system

SOLÀ has developed a unique, market-first tractor and drill adaptive weight distribution system for three-point linkage drills. It ensures a uniform seeding depth, regardless of speed or soil conditions, without the need for additional counterweights.

Seed dosage

"Precision Planting's Vacuum Seed Dispenser delivers ≥99 % accuracy. It is a proven solution with reliability and high quality, suitable for a wide range of seed types and sizes.

To maintain a uniform drilling depth, VELOX is equipped with a hydraulic pressure system. Hydraulic cylinders ensureto apply to each line equal pressureregardless of changing field conditions. When combined with the Adaptive Weight Transfer system on the tractor and drill, up to 350 kg pressure per rowwhich is sufficient even under the most demanding conditions.

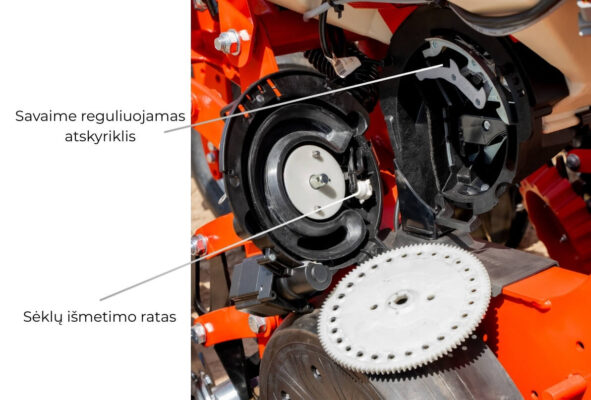

"Precision Planting Vacuum Seed Dispenser provides ≥99 % accuracy. It is a proven solution with reliability and high quality, suitable for metering a wide range of seed types and sizes. VELOX seed metering easy to adjust and maintain - The seed separator requires no adjustment and is equipped with a seed ejector wheel that clears the seed disc openings and helps prevent skips.

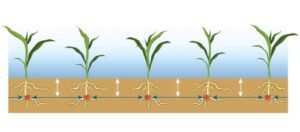

Ensuring that plants are properly protected and have access to specific nutrients at each stage of growth is essential to ensure their development and maximum yield. Up to two micro-products can be applied in the furrow between the closing wheels or seed openers or on the furrow behind the closing wheels. Spraying insecticides to protect the seed, initial fertiliser to stimulate plant development and promote rapid plant growth. Each product is precisely dosed ISOBUS compatible electric motors with section or queue management, optimising cost utilisation, reducing waste and protecting the environment.

Hydraulic pressure

Seed dispenser

Micro-product hoppers and dispensers

Numerous studies have shown that, of all the factors, it is the uniform germination of seeds that has the greatest impact on yield potential. Plants that germinate at least a day later than others receive less light and nutrients throughout the season, resulting in a significant reduction in yield. Depending on the degree of unevenness, the yield loss of maize can range from 5 % to 22 %. The main causes of uneven germination are uneven sowing depths and the ingress of plant residues into the furrow. It is therefore essential to avoid residues entering the furrow and to ensure a constant sowing depth - these two factors lead to uniform germination and higher yields. As working speeds increase and the soil surface is uneven or compacted, traditional row section pressure systems often cannot cope with vibration and bouncing, leading to problems with uneven depth and seed placement, which directly reduce yield potential.

The pressure of the VELOX row section is maintained by hydraulic cylinders which ensures equal force for each row and allows you to maintain a pre-set sowing depth independent of changing field conditions. The conveniently located one-point adjustment with pressure gauge allows you to quickly and accurately set the right pressure. With Adaptive Weight Distribution (AWT) system can be achieved up to 350 kg pressure per rowso no extra weight in the drill is needed.

SOLÀ's uniquely designed double disc tines feature an angle of just 9° between the discs. Such a low angle of penetration: Test results and practical use in a wide range of soils, climatic conditions and tillage techniques have confirmed that this the design ensures better and more uniform seed germinationwhich results in higher yields every year. Narrow angle of double discs combined with hydraulic pressure control guarantees uniform seed placement depth and creates the optimal conditions for each seed to develop for the highest results. Difficult soil conditions, direct stubble drilling, high working speeds and heavy attachments usually requires a higher clamping pressureto keep the tines in the soil. Traditionally, this has meant the need to increase the overall weight of the drill, but this leads to higher fuel consumption, a more complex design and additional operating and maintenance costs. SOLÀ has developed a unique, market-first tractor and drill Adaptive Weight Distribution (AWT) systemfor three-point linkage drills. It is ensures uniform sowing depthregardless of speed or soil conditions, without additional counterweights. The operator just needs to set the desired line section pressure and the system automatically apportions and transfers the required weight. When the AWT is switched on, the hydraulic cylinders, via a pulley system can carry up to 1000 kg the weight of the tractor on the drill frame, so that maximum downforce is maintained at all times. The system works fully automaticensuring that the drill has the weight it needs to carry, without causing excessive soil compaction or additional power requirements. When needed, AWT can be disabledgiving additional flexibility and control. "The Precision Planting Seed Dispenser ensures ≥99 % accuracy and is one of the most popular and versatile on the market. Its reliability and performance have been proven in a wide range of seed types and sizes - maize, sunflowers, soya, oilseed rape, sugar beet, cereals, etc. The Seed Dispenser is easy to adjust and maintain - the seed separator requires no regulation. It has a seed ejector wheel that clears the seed disc openings and helps prevent skips. The VELOX is controlled via ELEKTRA system, fully compatible with ISOBUSthat meets the latest requirements of Precision Farming 4.0 and offers many benefits to farmers. The seed metering units are driven by ELEKTRA stepper motors, ensuring wide range of operating speeds with high torque from very low revs and fast acceleration. This allows you to maintain high quality of dosing all over the field - especially after stops or at headlands. Row sections are supplied as standard with large 70 l seed hoppersensuring sufficient runtime without frequent replenishment. The hoppers are sealed to prevent moisture ingress and have convenient locks to prevent accidental opening. For more information visit the lines are numberedfor easier replenishment and maintenance. Each row can be provided with up to two 20 l microbead hoppers fertilisers and/or insecticides. ISOBUS-compatible electric drive motors provide full integration of control and monitoring via an ISOBUS terminal. Section management and line by line rate regulation Increases placement accuracy, saves chemicals and protects the environment. Using a universal screw dispenser a wide range of rates can be achieved, reducing operator exposure to chemicals. To keep the hoppers fully emptied, Drainage plugs under dispensers. To ensure maximum product efficiency, you can choose up to three insertion points: on the soil surface behind the closing wheels, in the furrow between the opening tines, in front of the closing wheels.Hydraulic pressure system

Double disc tine design

Adaptive Weight Distribution (AWT)

Seed dosage

Bunker system

The VELOX is a versatile solution that can be adapted to any task, crop, soil conditions or tillage technology. A wide range of options allows you to choose the most suitable configuration for the highest productivity and precision. With VELOX, farmers can choose between two fertiliser hopper solutions. Both hoppers are pressurised, with sealed lids and wide filling openings, ensuring a constant supply of product, easy filling and reduced replenishment requirements - saving time and increasing productivity. 1400 l drill-mounted hopper 1. Two large capacity dispensers powered by ISOBUS compatible electric motors. 2000 l front-mounted AURA hopper 1. A state-of-the-art solution for use not only with the VELOX seed drill, but also with other implements such as seed drills or cultivators, for sowing, fertiliser or micronutrient application. Single disc fertiliser tine Single disc 16" tines with strong compression springs for the toughest conditions. Working depth: 4-10 cm. Triple sealing protection ensures the durability of the bearings. Narrow, wear-resistant cast iron nozzle for long service life and minimum soil disturbance. Double disc fertiliser tine Double disc tines 15" - easy depth adjustment from 3 to 9 cm without tools. Mounted together with the row sections on the frame, it makes changing the row spacing quick and easy.

The SOLÀ ISOBUS-integrated ELEKTRA system controls, monitors and records the main drilling parameters and is fully compliant with Agriculture 4.0. The system has the following characteristics: All this helps to reduce losses, increase yields and ensure traceability in the supply chain. The TOUCH 800 universal terminal complies with the ISOBUS ISO 11783 standard and offers all the basic functions for working with ISOBUS equipment. Its 8" colour touch screen with protective touch-sensitive glass film ensures easy operation and reliable use. The TOUCH 1200 with its 12" monitor offers flexibility, versatility and easy operation. Its durability is ensured by an additional touch-sensitive glass film, making the terminal ideal for intensive, everyday work. The TOUCH 1200 can be used in both portrait and landscape positions and the display can show up to five functions simultaneously in a choice of layouts and interfaces.

SC (Section Control) - The section control function automatically switches off individual rows in an already sown area and switches them on one at a time in an area not yet sown. This precise and efficient control ensures that seed and fertiliser are applied only where they are needed, saving significant amounts of inputs and avoiding yield losses due to overcrowding. Farmers benefit from section management through higher yields, lower input costs, higher productivity and optimised seeding patterns. TC (Task Control) - The Task Controller function synchronises the data exchange between the ISOBUS-compatible device and your PC, allowing data transfer in both directions. The function allows precise coordination of drilling operations, simplifying and automating the management of complex farm tasks. VRA (Variable Rate Application) - Variable Rate Application Tool with optional Multi Control allows you to use control maps to distribute seed and fertiliser by zone, ensuring that every part of the field receives the right amount of fertiliser for optimal plant growth, resulting in higher yields and lower costs. TL (Track Leader) - When connected to a DGPS receiver, this application allows parallel, end-to-end or loop driving, also in low visibility conditions. Obstacles can be marked and saved together with plot boundaries and orientation lines. When work is interrupted, it can be saved and restored at any time.Customisable solutions with a single row section

Fertiliser Insertion Additives

2. Capacity - up to 400 kg/ha at 16 km/h (8 rows with 75 cm row spacing).

3. The air flow system maintains uniform distribution of fertiliser across all rows without the risk of blockages.

2. Available with one or two electric motor-operated dispensers as required.

3. Control is possible via ISOBUS terminal or individual monitor.Control terminals

1. Simple set-up.

2. Precise control of seed and fertiliser placement.

3. Working with management maps.

4. Accurate recording of work actually done.All terminals can be pre-installed with a range of applications tailored to farmers' practical needs

Seed dispenser: Vacuum dispenser with electric drive motors Seed hoppers: 70 litres each, with moisture-proof lids and locks Pressure from the Norages: Hydraulic cylinders per row - up to 350 kg of pressure / Springs with 6 positions - up to 250 kg of pressure Weight distribution system: Hydraulic, with proportional weight transfer, up to 1000 kg extra load on the frame Closure system: Two closing wheels with angle adjustment and 6 pressure settings up to 53 kg Fertiliser system: High capacity, with a choice of front hopper or drill-mounted hopper Drill hopper: 1400 l pressure hopper (except PF 300/8, PF 300/9, PV 300/12 models) Front bunker: AURA 2000 l pressure hopper Fertiliser dosage: Modular volumetric dose units with ISOBUS electric actuators Fertiliser distribution: Hydraulic turbine drive Fertiliser tines: 16" single disc or 15" double disc tines Microproduct insertion: Up to 2 hoppers per row, each with a capacity of 20 litres, with ISOBUS electric actuators and a choice of 3 different insertion points Residue cleaners: Floating design with easy height adjustment, 350 mm sprockets and optional 255 × 45 mm side wheels Turbodisk + residue wipers: Includes a 16" single disc tine with 4 depth settings and residue wipers Hydraulic line markers: Optional equipment Tractor hydraulic system requirements: Requires Closed Centre hydraulic system, maximum flow: 40 l/min (70 l/min with fertiliser system) Number of hydraulic connections:

Model TV300/6 TV300/6 TV300/7 TV300/7 S TV300/8 TV330/8 TV300/9 TV330/9 PF300/8 PF300/9 PV300/12

Frame type Telescopic Telescopic Telescopic Telescopic Telescopic, double Telescopic, double Telescopic, double Telescopic, double Folding Folding Folding

Number of rows, pcs 6 6 7 7 8 8 9 9 8 9 12

Midway adjustment Hydraulic adjustment, every 5 cm Hydraulic adjustment, every 5 cm Hydraulic adjustment, every 5 cm Hydraulic adjustment, every 5 cm Hydraulic adjustment, every 5 cm Hydraulic adjustment, every 5 cm Hydraulic adjustment, every 5 cm Hydraulic adjustment, every 5 cm Manual Manual Manual, continuous

Interline 45-75 cm 50-80 cm 7 rows 45-60 cm

6 rows 70-80 cm50-80 cm 40-75 cm 45-80 cm 9 rows 40-55 cm

8 rows 65-75 cm9 rows 40-60 cm

8 rows 70-80 cm70-80 cm 60-65 cm 12 rows 45-50 cm

9 rows 65 cm

8 rows 70-80 cm

Tractor power requirement ≥ 120 HP ≥ 120 HP ≥ 130 HP ≥ 140 HP ≥ 160 HP ≥ 160 HP ≥ 160 HP ≥ 160 HP ≥ 160 HP ≥ 180 HP ≥ 180 HP

Transport width, m 3 3 3 3 3 3,3 3 3,3 3 3 3

Technical specification for all models

AGRICULTURAL MACHINERY SOLÀ, SL was founded 50 years ago. The factory is located in Calaf, Barcelona province, Spain.

Having started by selling agricultural equipment and gaining experience, the company began to design and manufacture mechanical seed drills, which were renowned for their robust construction and reliability.

SOFA The seed drills are manufactured using many years of experience, with special attention to strength, reliability and durability. There are currently over 20,000 used seed drills on the market.