Robust, reliable mulcher - 20-50 hp for tractors and other machinery

One solution for all - all in one

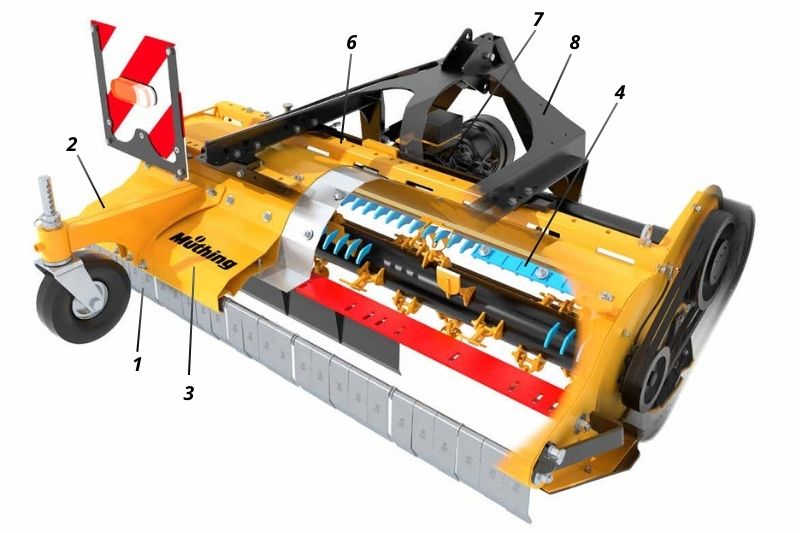

Flexible and reliable mulcher based on a modular system.

- Operating power range: 20-50 hp.

- Various hydraulic actuators for throughputs of 35-70 l/min (gear motor or axial piston design).

- Working widths: 1.20 m / 1.40 m / 1.60 m.

- Optimised front support wheels with easy-to-access maintenance points.

- Improved drive concept.

- Variable connection points for all fixings and support legs.

- Newly designed convenient adjustment of the support roller.

- A lightweight and noise-reducing plastic protective sleeve is available as an option.

- Additional options are available.

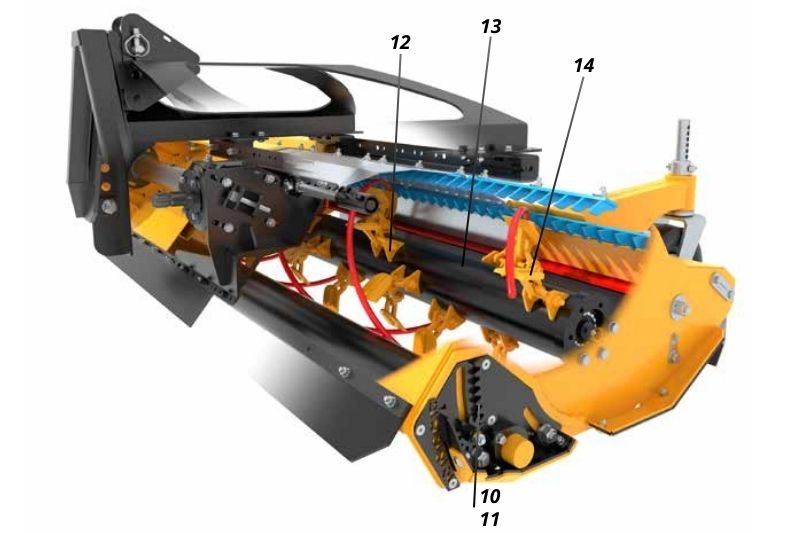

MU-FM Vario / MU-FM Vario Hydro Mulchers

MU-Vario® system

The ability to conveniently adjust the mulcher to different working height requirements allows for efficient handling of both finely chopped plant residues and dense, green turf.

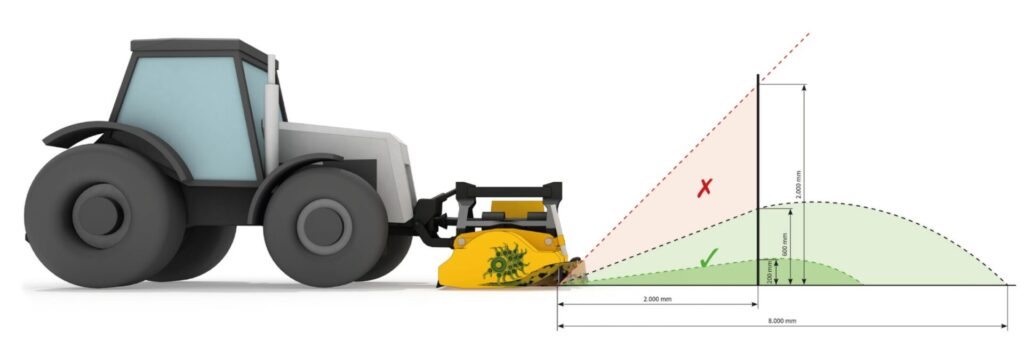

Stone throwing certificate issued by TÜV Nord

Müthing, in cooperation with TÜV NORD, has successfully tested all mulchers with a working width of up to 3.2 m for objects thrown during operation. As a result, safety distances are reduced to 2 m on the sides and 8 m in front and behind the machine.

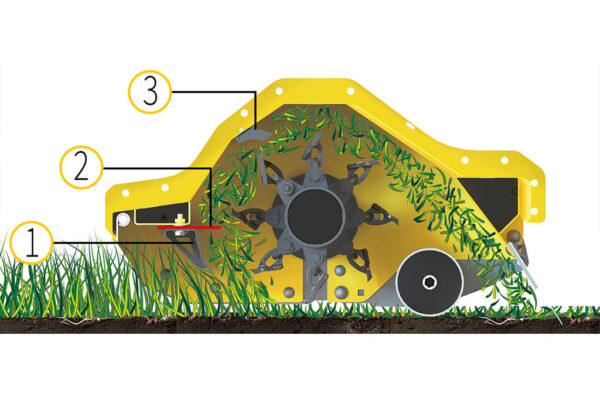

Tungsten Carbide "M" Shape Hammers

A versatile solution for landscape maintenance. The straight blade made of DuraX steel ensures an even cutting pattern and significantly increased wear resistance. The tool features increased cutting momentum and even weight distribution.

Shark fin shredding bar with shark fins

The system ensures even shredding of all plant residues: longer materials are returned for additional processing, and once properly shredded, they immediately move on.

Functionalities

- Simple management, maximum flexibility, exceptional quality of work.

- Robust construction and high performance for all applications.

- Minimum safety distance approved by the TÜV Nord Technical Inspection Association.

- Insect-friendly cutting - with optional insect rescue device and four-wheel chassis.

- Individually selectable configuration options allow for optimal attachment to various vehicles.

- A hydraulic actuator for front mounting is available as an option.

- The tungsten carbide "M" shaped hammers combine wear resistance with high chopping quality.

- The short Shark fin shredding bar ensures optimal material flow and excellent mulching results.

- Support roller for adjusting the working height.

- Mulcher suitable for both front and rear mounting - for use with tractors and other machinery.

- "The Vario counter-knife allows you to adjust the chopping length.

- A wide range of gearbox options are available, depending on position, speed and direction of rotation.

Every detail is designed to work together to create the perfect mulcher for your fields.Why do Müthing mulchers exceed expectations?

Müthing mulchers – certified by TÜV Nord for the distance of thrown objects

The MU-FM Vario / MU-FM Vario Hydro Mulchers also offer the following advantages

flexible and robust thanks to versatile configuration options.

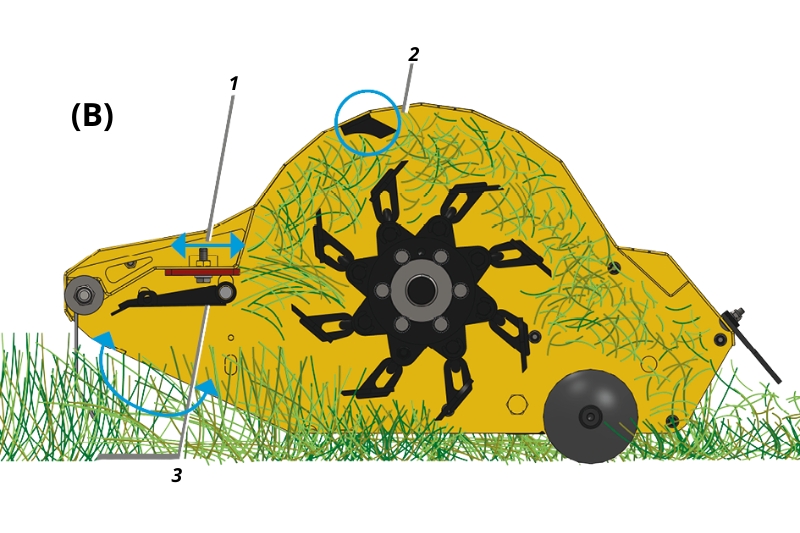

with low cutting angle (1), Vario counter-blade (2) and Shark fin shredding bar (3) Maximum safety and worry-free work - by maintaining safety distances: 8 meters in front and behind, 2 meters on the right and left sides.

The new MU-FM Vario series with an intelligent modular system:

MU-FM Copper cut

Müthing mulchers - always one step ahead with certified safety!

Tungsten Carbide "M" Shape Hammers

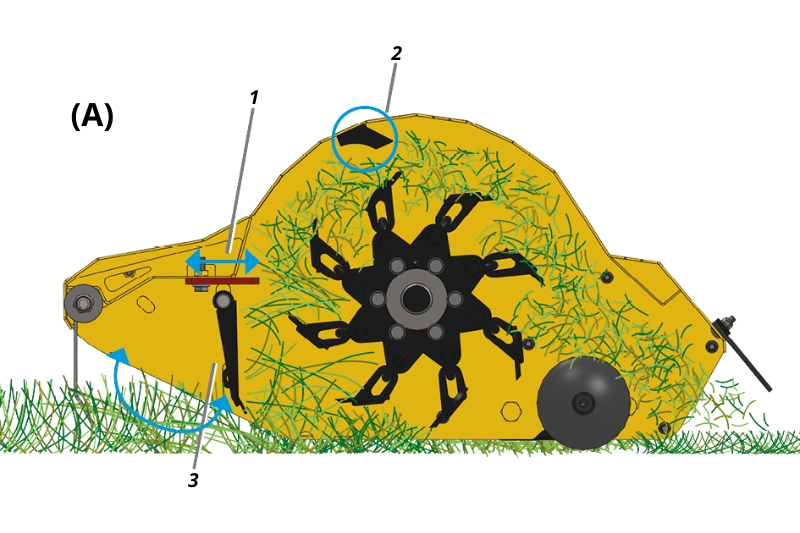

MU-Vario® system - full control of working conditions. Optimum suction, adjustable body shape, adjustable PTO speed, infinitely adjustable back knife and adjustable low-cutting throttle make it easy to adapt to any field conditions.

Individual settings for different situations and materials: grass, reeds, bushes, leaves and branches.

The adjustable front knife allows you to easily adjust the chopping intensity to suit conditions and needs.

The adjustable low-cutting flap gives the mulcher versatility and adaptability to a wide range of conditions and requirements (available as an option for MU-E Vario and MU-E/F Vario and as a short-cutting angle for MU-Collect Vario). (Diagram A) The low-cutting valve is down:

(Diagram B) The low-cutting flap is up:

MU-Vario system – for maximum working comfort and flexibility

Universal use – optimal treatment for all crops

Flexible adjustment of the grinding intensity

MU-Vario system operating concept:

1. The adjustable counter knife allows for infinitely variable adjustment of the chopping intensity to suit specific requirements.

2. Shark fin system:

3. The adjustable low-cutting flap makes the mulcher suitable for year-round use.

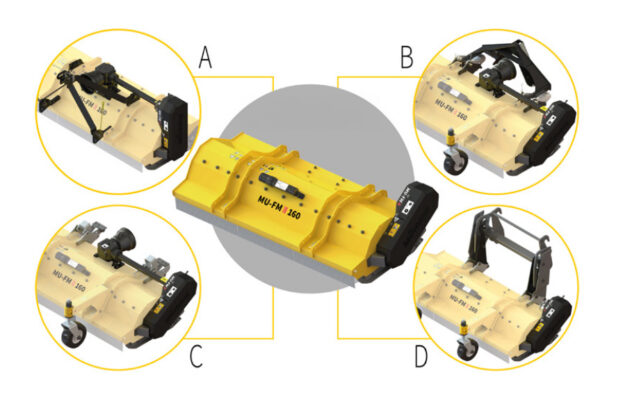

The mulcher can be used with a wide range of machines thanks to its various coupling options, modular system and flexible design. Müthing modular principle with configuration examples: A: Front/rear attachment with 3-point connector;

Müthing MU-FM VARIO front mount with 3-point connector, category 1. Müthing MU-FM VARIO front mount with 2-point connector. Müthing MU-FM VARIO rear mount with 3-point connector, category 1.

Front hydraulic attachment for Weidemann machines. Müthing MU-FM VARIO front mount with 2-point connector.Optional equipment

B: Front fixing with connecting triangle;

C: Front fixing with 2-point connector;

D: Front attachment with hydraulic actuator.

| MU-FM Vario front | front-rear | Hydro | 120 | 140 | 160 |

|---|---|---|---|

| Working width (cm) | 120 | 140 | 160 |

| External width (cm) | 145 | 165 | 185 |

| Maximum tractor power at 2200 rpm | 20-50 | 20-50 | - | 20-50 | 20-50 | - | 20-50 | 20-50 | - |

| Weight (kg) | 236 | 227 | 224 | 253 | 244 | 241 | 270 | 261 | 258 |

| Number of tungsten carbide "M" hammers | 20 | 24 | 28 |

| Oil flow, l/min | - | - | 35-70 | - | - | 45-70 | - | - | 45-70 |

Muthing German quality and reliability Wide selection Modern and sustainable solutions

This is a German manufacturer with over 120 years of experience in producing high-quality mulchers for agriculture, landscaping and gardens. The company began operations in 1898 and introduced its first mulchers in 1998. Today, it is a fourth-generation family business.

All Müthing implements are developed and manufactured in Germany, in accordance with high quality and safety standards. Much attention is paid to durability, practicality and resistance to intensive work. These mulchers are extremely efficient in shredding plant residues and adapt to various working conditions. Müthing, in cooperation with TÜV NORD, has carried out and successfully passed tests for the ejection of objects during work on all mulchers with a working width of up to 3.2 m. Therefore, when using a Müthing mulcher, you ensure maximum safety for yourself and those around you.

Müthing offers more than 1,500 mulcher models: mounted, foldable, mounted and trailed, for front, rear or side work. Available working widths range from 0.80 to 8.60 m. This variety of models allows every farm to find the most suitable solution.

The manufacturer works closely with scientists and customers from different countries. Solutions such as the MU-Vario system allow you to adjust the mulching as needed. At the same time, technology is being developed that contributes to insect protection and maintaining the ecological balance in the fields. Certified safety tests ensure safe work even near roads or settlements.