Advanced mixer-dispensers with three mixing screws and a capacity of 28.5-45 m³

28,5–45 m³ talpos mixers-dispensers – idealus sprendimas dideliems bei sparčiai augantiems pieno ūkiams

High quality and efficient work

- 28,5–45 m³ talpos.

- Vienu įkrovimu pašeriama 140–320 karvių.

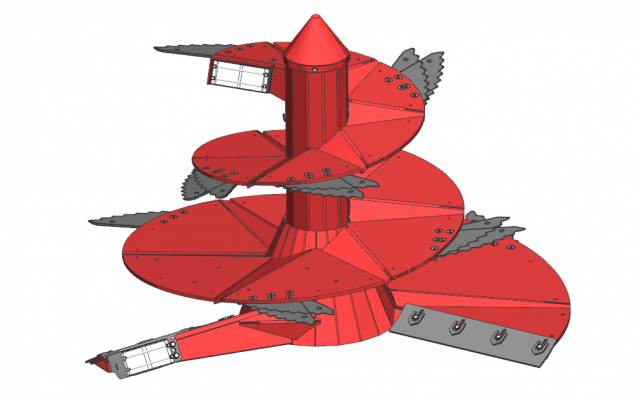

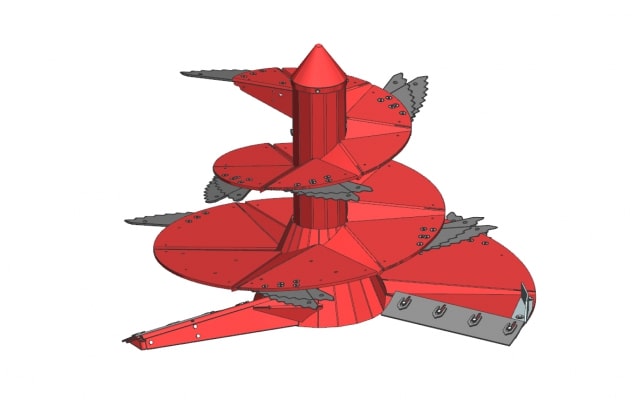

- Trys IMS maišymo sraigtas.

- Unique mixer shape ensures smooth and fast mixing process.

- Patented solution – as the herd grows, the mixer-distributor can be easily enlarged by adding extensions.

- 180 mm or 360 mm elevations.

- Various unloading options.

- Electronic scales.

- Creating a uniform and optimal diet.

Highlights of STRAUTMANN Verti-Mix

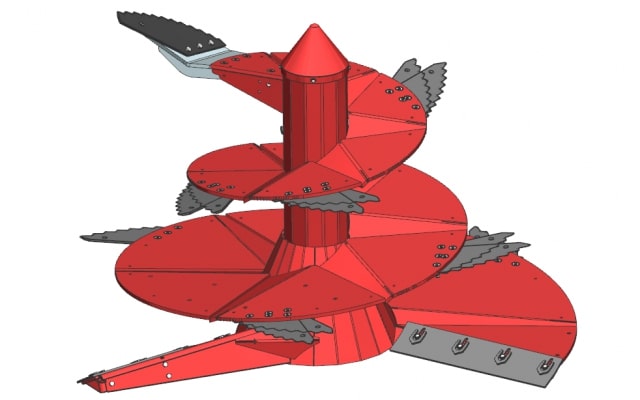

Innodur® technology

The optional INNODUR® abrasion-resistant elements significantly extend the life of the IMS mixing screw. These 5 mm thick and 100 mm wide stainless steel elements are attached to the screw coils by overlapping screws and can be retrofitted if required.

Promotions

Patented solution - as the herd grows, the mixer-distributor can be easily enlarged with the addition of a step up. The hopper ring at the top provides extra strength and stability and prevents overflow. It is used as a base for the extension (0 mm - 180 mm - 360 mm) to increase the available capacity of the divider if needed.

Different ways of unloading

STRAUTMANN Verti-Mix feed dispensers can be equipped with a variety of unloading options to suit the needs of each farm. Choose from side discharge, front discharge, rear discharge, conveyor discharge or any other solution that suits your farm. It is also possible to have several unloading options in one unit.

Suitable for old-style sheds

Their compact dimensions and manoeuvrable design make them easy to move even in narrow feeding lanes, making feeding convenient and efficient in all conditions. It is the perfect choice for farms with older barns where space is limited but modern and reliable equipment is desired. In addition, the dispensers do not require high tractor power and can be used even with older tractors.

Speciali bunkerio geometrinė forma užtikrina tobulą vertikalų ir horizontalų maišymą.

Thanks to the patented blade adjustment system, the IMS mixing screw can be ideally adapted to the specific conditions of use. The robust and low-maintenance bevel gear ensures a long service life even under difficult working conditions.

The optional INNODUR® abrasion-resistant elements significantly extend the life of the IMS mixing screw. A reinforced version of the IMS mixing screw with 20 mm thick coils is available on request, providing a 50 % longer lifetime (which means 50 % less wear and tear).

Ring from transfusion

180 mm elevations

360 mm elevations

Unique faucet shape

Trys IMS maišymo sraigtai

Innodur® technology

Magnet system

Ring from transfusion and promotions

Additional Verti-Mix benefits with the choice of litter spreading system equipment. Spreading litter by roller

Strautmann offers management solutions tailored to individual needs. Direct control from the tractor

Bowden cable control

Electric control

PTM HL 50 - programmable weighing system without data transmission Basic model of Strautmann weighing machines

PTM Advance Super USB - programmable weighing system with data transmission Comprehensive feeding management with time recording is the basis for efficient cost optimisation on a dairy farm.

PTM AV 75 - remote control Suitable for PTM HL 50 and PTM Advance Super USB weighing systems.

Various unloading solutions to suit your farm's needs

Litter spreading system

Management

Weighing system

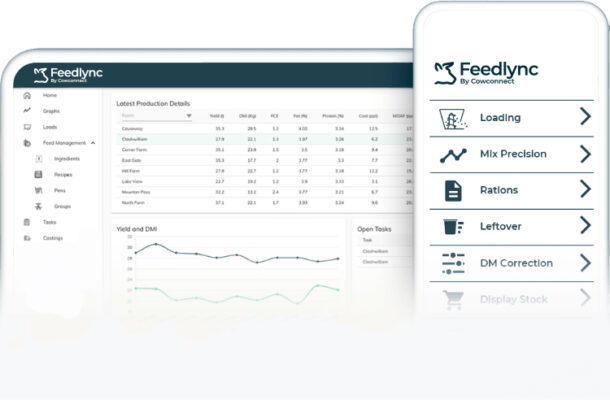

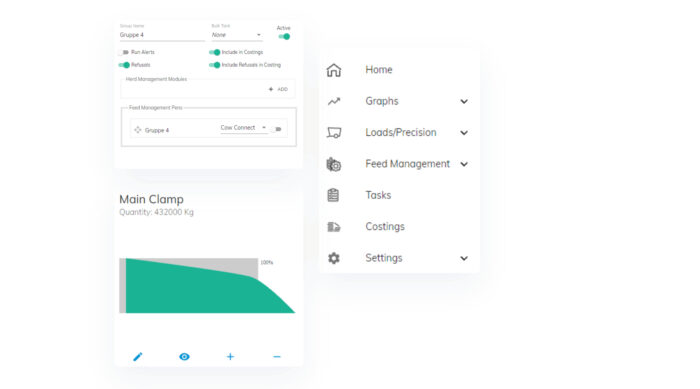

A unique cloud-based solution that will help you accurately track, manage, and otherwise streamline feeding operations.

Feedlync seamlessly integrates with your farm's external systems and automatically imports milk yields and cow numbers. Stay connected to your farms and feeding process, get automated, reliable data instantly, work proactively with multiple farms by viewing their data. Change rations, add or remove ingredients, manage pens and groups remotely. Feedlync integrates with several external systems to provide accurate and detailed costing. Feedlync has a lot of features that help you save time and work more efficiently

Active monitoring Track feed consumption, price per liter and more. Real-time data exchange Get data to your app in real time from anywhere in the world. Weather corrections Adjust the feeding plan to ensure that weather conditions do not affect milk yield. Low stock alerts You will be notified when the stock of silage or other feed reaches a defined minimum quantity. Farm data interfaces Feedlync integrates with other systems, saving you time and money. Saved reports Change saved recipe data to avoid feed waste and increase profits. Cloud backup Copies of your data are automatically saved, without the risk of losing anything. Charts and analysis The app helps you clearly see and understand the collected data and costs. Animal health Accurate feeding data provides the best understanding of your animals' health.Feedlync intelligent feeding management system

Router

Feedlync integrates with your existing systems

Data at your fingertips

Direct monitoring of farm expenses

But that's not all.

| Verti-Mix 3451 Triple | Verti-Mix 4501 Triple | |

|---|---|---|

| Useful capacity, m³ | 28,5 | 31,5 | 34,5 | 38 | 41,5 | 45 |

| Length, mm | 9 430 | 9 940 |

| Width with cross conveyor, mm | 2 280 | 2 420 |

| Width with one-sided unloading, mm | 2 380 | 2 520 |

| Width with double-sided unloading, mm | 2 480 | 2 620 |

| External width between wheels, mm | 2 170 | 2 360 |

| Heights, mm | - | 180 | 360 | - | 180 | 360 |

| Length with front cross conveyor, mm | 10 150 | 10 660 |

| Unloading height, mm | 1 100 | 1 050 |

| Unloading height with cross conveyor, mm | 790 | 810 |

| Distance between centre of towing eyelet and centre of axle, mm | 5 860 | 6 000 |

| Distance between the centre of the towing eyelet and the centre of the axle when the front cross conveyor is fitted, mm | 6 590 | 6 720 |

| Net weight with double-sided crossbar, kg | 10 874 | 10 987 |11 100 | 13 258 | 13 379 | 13 500 |

| Kerb weight with cross conveyor, kg | 11 174 | 11 287 | 11 400 | 13 558 | 13 679 | 13 800 |

| Permissible load on the coupling loop, kg | 2 000 | 2 000 |

| Axle load, kg | 9 000 | 8 000 |

| Permissible gross weight (15 km/h), tandem chassis, kg | 26 000 | - |

| Leistina bendroji masė (15 km/h), trijų ašių, kg | 38 000 | 38 000 |

| Permissible gross mass (25 km/h, StVZO), tandem chassis, kg | 20 000 | - |

| Leistina bendroji masė (25 km/h, StVZO), trijų ašių, kg | 26 000 | 26 000 |

| Intersection, mm | 1 730 | 1 800 |

| Wheelbase, mm | 1 360 | 1 360 |

| Wall thickness, mm | 8 | 8 |

| Bottom thickness, mm | 20 | 20 |

| Internal length of hopper with overflow ring, mm | 7 480 | 8 090 |

| POWER NEED | ||

| With 2-speed gearbox (12.8/23 rpm), kW/HP | - | 125/170 | 132/180 | 139/190 |

| With 2-speed gearbox (14.4/26 rpm), kW/HP | 103/140 | 110/150 | 117/160 | - |

| With 2-speed gearbox (16.7/30 rpm), kW/HP | 117/160 | 125/170 | 132/180 | - |

| TYRE HEIGHT (TANDEM CHASSIS) | ||

| 435/50 R 19,5, 1930 mm track, m | 2,90 | 3,08 |3,26 | - |

| 235/75 R. 17,5, dvigubos, m | 2,80 | 2,98 | 3,16 | - |

| 455/45 R 22,5, m | 2,94 | 3,12 | 3,30 | - |

| AUKŠTIS PAGAL PADANGAS (TRIJŲ AŠIŲ) | ||

| 235/75 R. 17,5, double, 1720 mm track, m | 2,80 | 2,98 | 3,16 | 3,13 | 3,31 | 3,49 |

| 435/50 R 19,5, m | 2,90 | 3,08 | 3,26 | 3,23 | 3,41 | 3,59 |

| 455/45 R 22,5, 1720 mm track, m | 2,94 | 3,12 | 3,30 | 3,27 | 3,45 | 3,63 |

A family-run company based in northern GermanyB. Strautmann & Söhne GmbH u. co. KG"has been around for over 85 years.

STRAUTHMANN The factory has developed a wide range of products, especially well suited for livestock farms. The company can offer silage handling equipment for various purposes: silage buckets, silage cutters and silage block cutters for easy silage removal.

STRAUTHMANN Silage block and feed transport trailers have been ensuring fast and easy feed supply for several decades. We also manufacture trailed and self-propelled feed mixers - perfect for preparing physiologically ideal animal feed.

For optimal feed quality, STRAUTHMANN presents grass silage handling equipment. In order to maintain the best quality of feed, the grass loaded into the self-loading trailer is gently but optimally chopped. Customers can purchase tri-axle trailers and dump trucks as well as trailers for convenient feed transportation. Also, manure and universal shakers are available in various sizes. Thus, by creating a high-quality and diverse product offering, STRAUTHMANN the company becomes a competent partner for the farmer.