Compact disc seed drills suitable for tractors from 140 HP. Robust construction, precise sowing and a capacious seed hopper.

Compact 3 / 4 / 6 / 7.2 meter working width seed drills with fertilizers

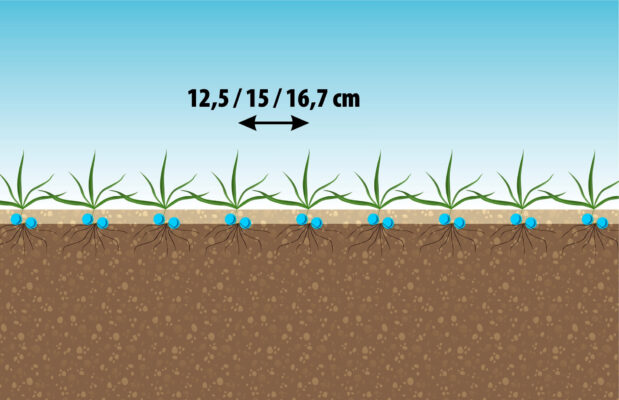

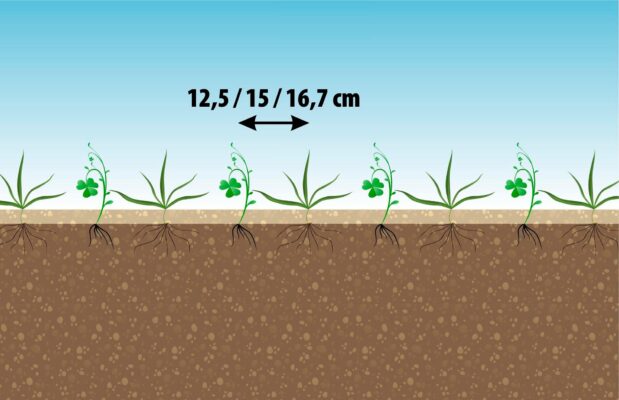

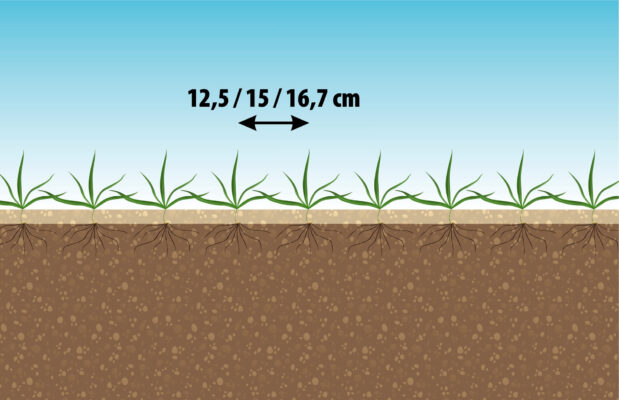

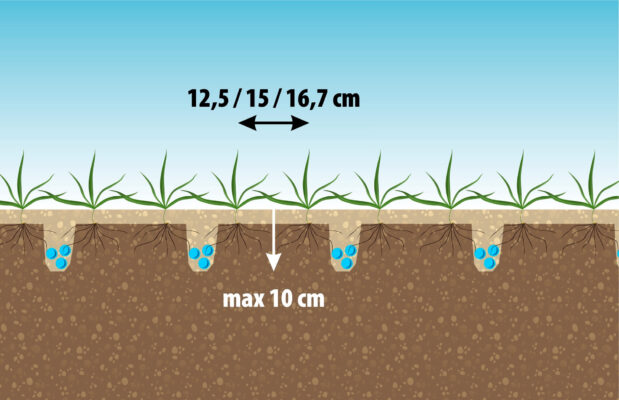

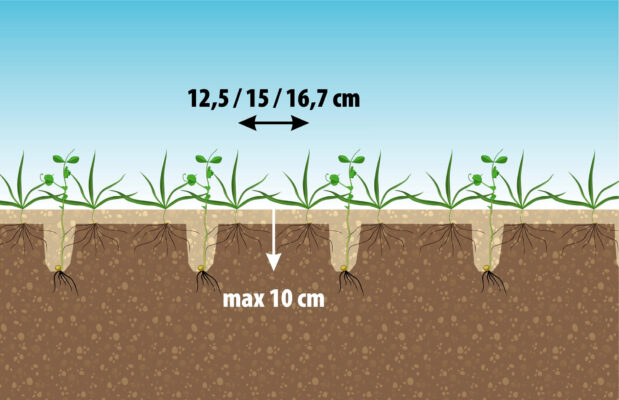

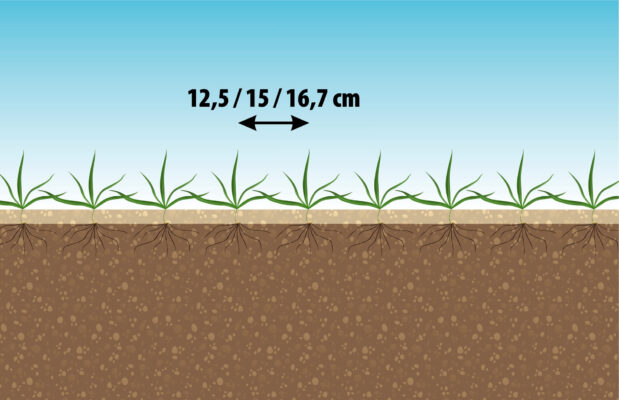

Falcon Compact models do not require a very powerful tractor, they are designed sowing of all traditional crops 125 / 150 / 167mm row spacing, also suitable for sowing and unprepared soil. The drill can be optionally equipped with or without fertilizer application.

Sowing, fertilizing and cultivating – in one pass

Falcon COMPACT drill with a wide sowing range – from 0.5 to 350 kg/ha in one go cultivates the soil, prepares the seedbed, compacts the soil, and sows seeds and applies fertilizer with high quality.

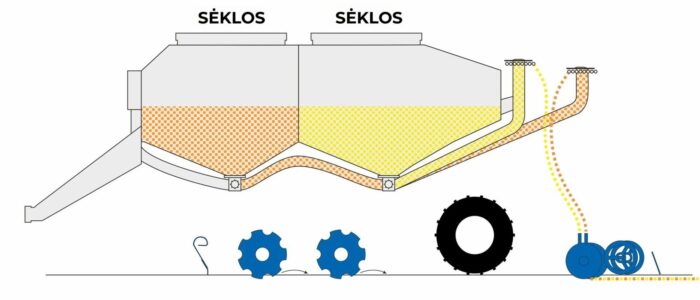

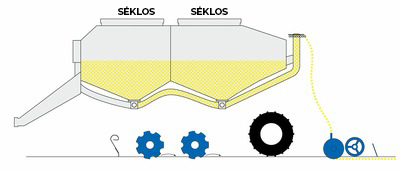

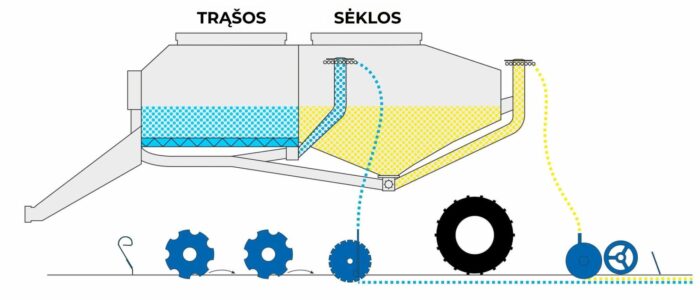

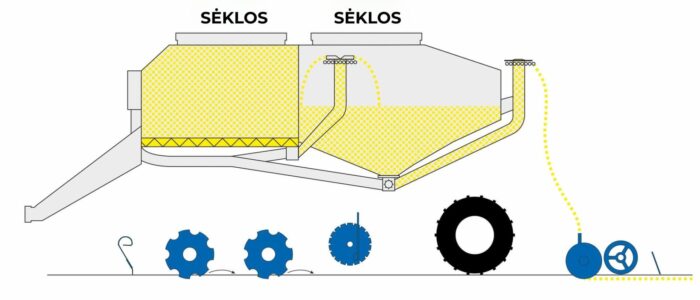

Falcon Compact FertS

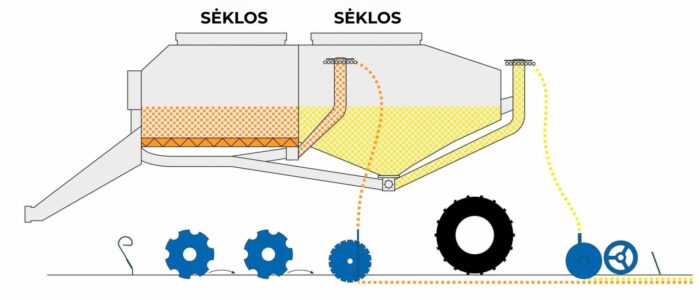

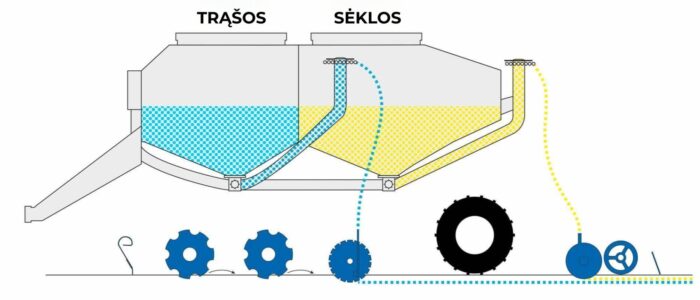

Falcon Compact Fert+

Seeding zones

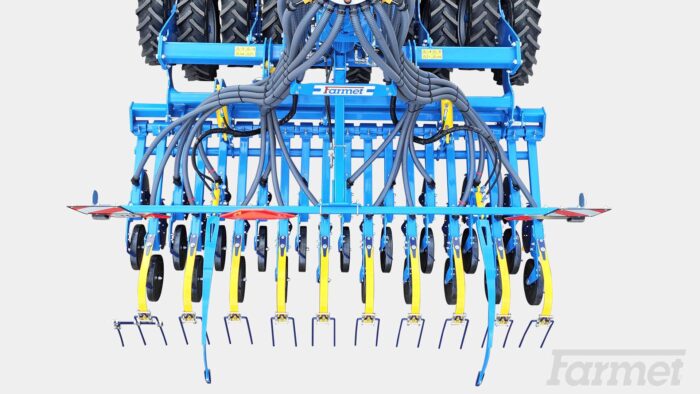

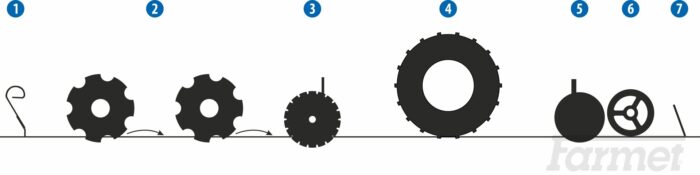

With Falcon Compact seed drills, 7 operations are performed in one pass:

1. Primary soil leveling zone. A precisely leveled surface allows for even consolidation and loosening of the soil for sowing.

2. Soil preparation zone. The soil can be cultivated with various tillage sections – across the entire sowing width or in zones up to 10 cm deep. Primary cultivation enriches the soil with air, levels it and optimally loosens it. It also spreads plant residues.

3. Fertilizer application area. Granulated fertilizer is applied to the root zone of the future plant - directly under each row or between two rows.

4. Soil compaction and deep soil capillarity restoration zone. Good compaction ensures effective water infiltration to the soil surface even in dry conditions.

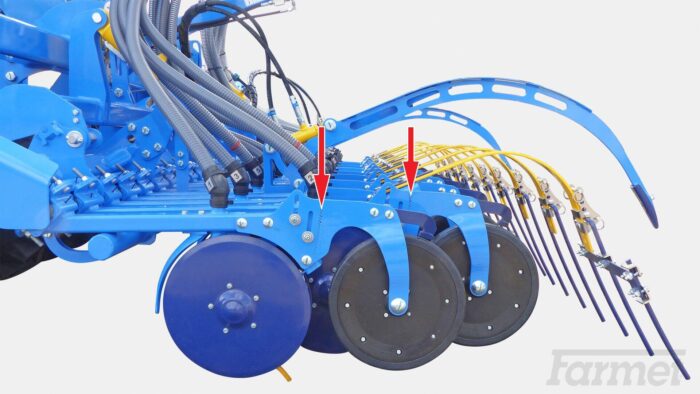

5. Soil formation for sowing and seed placement zone. The double disc sowing discs effectively form a compacted soil for sowing (V-shaped furrow) and precisely place the seed at the required depth. Due to the high downforce, up to 70 % machine weight can be transferred to the sowing discs. The compacted soil for sowing and the V-shaped furrow ensure excellent seed contact with the soil and soil moisture.

6. Lateral seed pressing zone. The copying wheel presses the V-shaped groove with the seed, thus compressing the seed with the soil from the side. The soil above the seed remains loose, which significantly improves seed germination.

7. Seed covering and soil leveling zone. Integrated tines ensure excellent seed covering and precise soil surface leveling.

Comparison of Falcon PRO and Falcon Compact seed drills

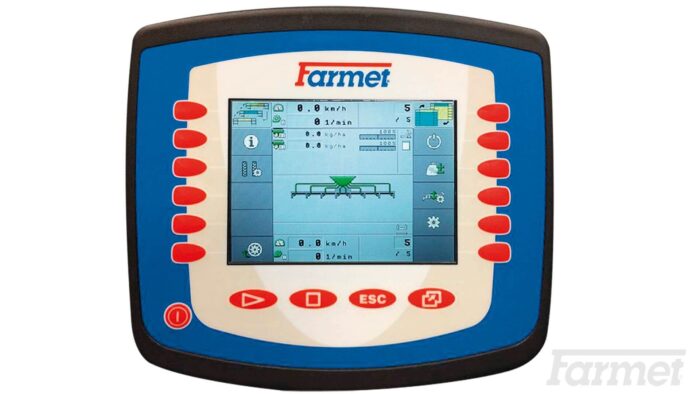

Fully electronic control and monitoring of drill functions

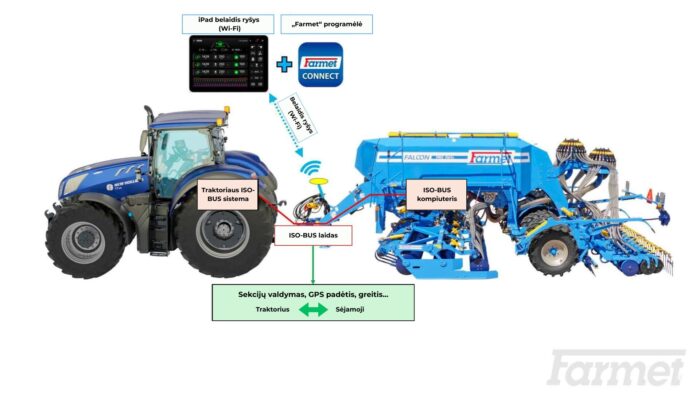

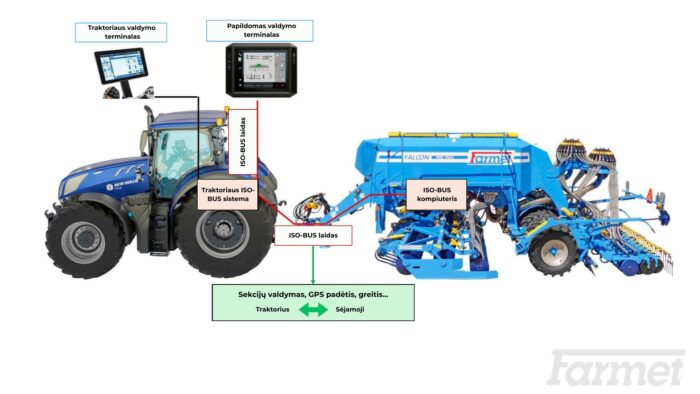

ISO-BUS electronic system with iPad terminal.

Electric metering unit with fully automatic seeding control, depending on the current working speed.

Optoelectronic monitoring of the seed flow to each individual sowing disc.

Section Control – automatic section shut-off

- Optimal sowing in corners and at the end of the field without overlaps or gaps.

- Freely adjustable section shut-off width.

- The smallest section is 1 sowing disc.

- The edges of the field are sown after the main part of the field has been sown so that the plants germinate evenly and with good quality.

- Seed saving.

- Compatible with ISO-BUS electronics.

Clear visualization of the sown area in the tractor terminal.

The crop was harvested using a Falcon seed drill controlled by individual seeding discs.

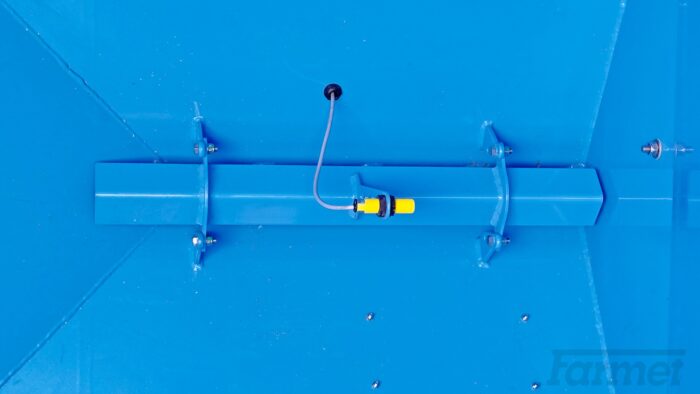

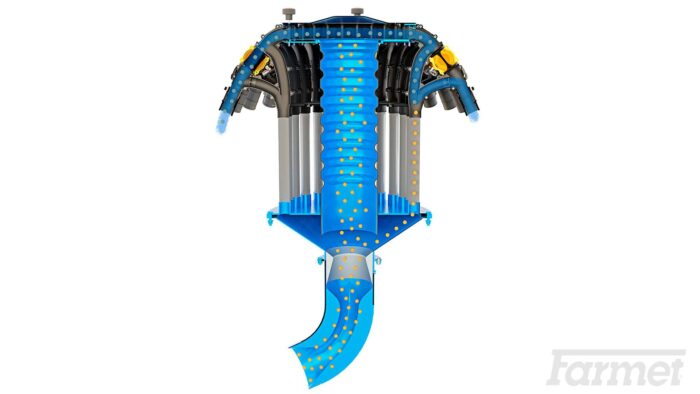

Reliable and precise seed flow control using pneumatically operated valves.

Fully equipped distributor for individual seed flow control to each sowing disc.

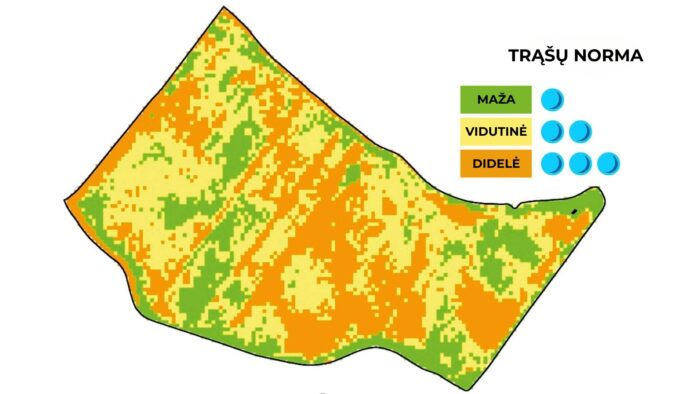

Variable fertilizer and seed dosage rate

The electronic system of the drill communicates with the tractor via ISO-BUS

Planter control via iPad with wireless (Wi-Fi) electronics – Farmet CONNECT

Control via tractor terminal or additional display with Müller Electronics system

High quality and efficient work

- Large working speed – 10–20 km/h.

- Low weight determines low resistance

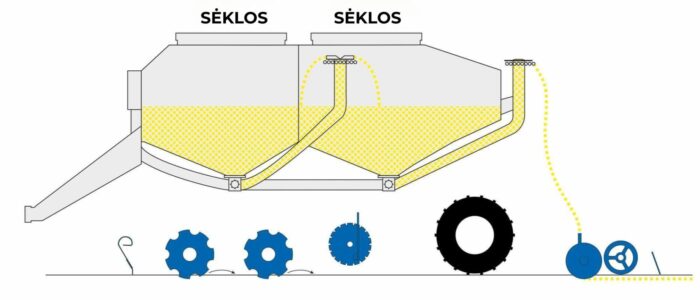

- Large seed box capacity allows you to sow a large area without filling the drill

- The compact and short design of the drill allows to turn quickly in the headlands

- Precise depth support for optimal soil compaction

- Excellent surface smoothing and compaction before each sowing disc

Wide wheels for 125 / 167 mm row spacing Narrow wheels for 150 mm row spacing

Used for production extremely high quality materials and applies eXtra STEEL line The technology guarantees long-term use even in the most difficult conditions – due to the high elasticity of the frame and the low weight of the machine itself.

Maintenance-free bearings Maintenance-free mounting points for the sowing discs

The minimal number of adjustment and lubrication points ensures that working with the machine, its operation and subsequent maintenance are extremely simple and easy for everyone to master.

Setting the working depth of the tillage section Seed rate determination

Front pneumatic roller Seedbed preparation

Adjusting the sowing depth Double seeding discs

Roller dispenser "FertS"

Falcon Compact 4 seed drill

2. Rubber wheel roller for optimal soil compaction.

3. Double disc sowing discs with fixed row spacing – 125 / 150 / 167 mm.Falcon Compact 6 seed drill

2. Rubber wheel roller for optimal soil compaction.

3. Double disc sowing discs with fixed row spacing – 125 / 150 / 167 mm.Wheel selection

Lightweight but sturdy frame

All 490 mm diameter discs are mounted for completely lubrication-free operation – with rubber overload protectors.

The durable and maintenance-free rubber mounting of the seed discs helps adapt to the terrain and provides protection against overloads.Easy to use

Easy adjustment of working depth according to a clearly understandable scheme using spacers on the piston rods.

Easily accessible seed dispenser with replaceable coils.Intelligent machine design

Pneumatic roller with reinforced wheels for additional soil compaction. This is an optional additional equipment for the machine.

The two-row disc cultivation section perfectly levels the soil surface in the transverse direction and loosens the soil at the level of the seed base.

Possibility of separately adjusting different sowing depths for even and odd sowing discs.

Thanks to their proven design, they penetrate the soil perfectly even with a large amount of crop residue and, together with the press wheel, place the seeds at the set depth.Roller fertilizer dispensers

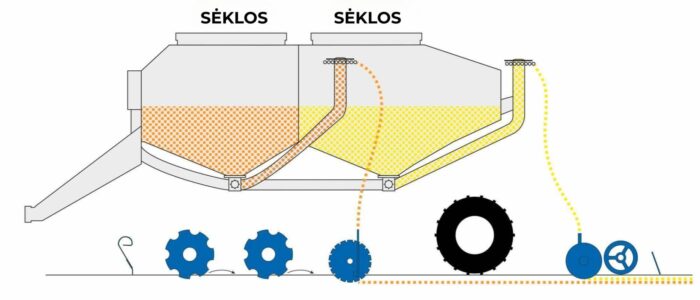

Modern roller dispenser with replaceable rollers. The fertilizer is directed directly to the seed.Metering reels for all types of seeds

iPad wireless connection (Wi-Fi)

Track valves For saving seeds and fertilizers. Section management

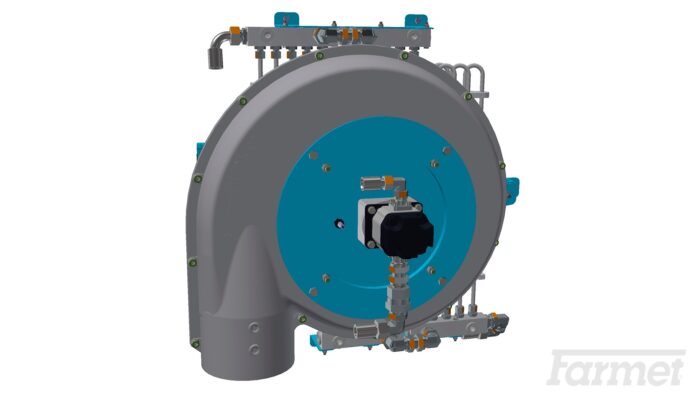

Fan with cooler "Y" adapters for connecting seed tubes - ½ row spacing sowing

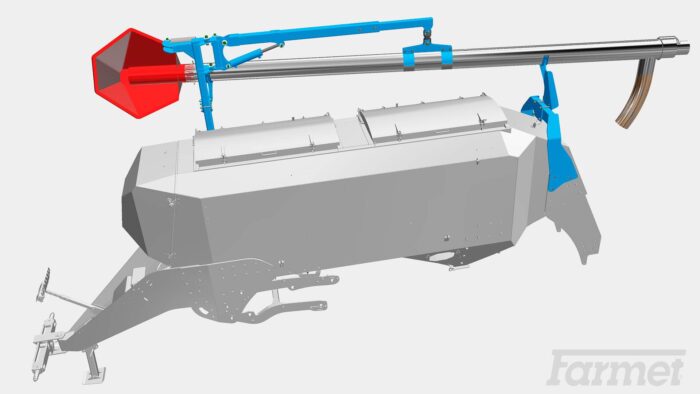

Filling screw Lighting

Hydraulic motor for fan drive via tractor PTOControl terminals

Seed counting and sowing control for each individual sowing disc.

iPad wireless connection (Wi-Fi) Topcon XD+ ME TOUCH800® BASIC terminal ME SMART570®

Screen dimensions 11" 12,1" 8" 5,7" 5,7"

Seed passage sensor control + + + + +

Seed hopper level indicator + + + + +

Fan speed monitoring + + + + +

Metering speed monitoring + + + + +

Engine speed monitoring + + + + +

Number of dosing motors 3 3 3 3

Track flap control + + + + +

Drill position display + + + + +

Work lighting control + + + + +

Seed box lighting control + + + + +

Marker control + + + + +

Prenatal marking management + + + + +

Seed replenishment during work + + + + +

Sowing small seeds + + + + +

Simultaneous windows 5 2 1 1

Video camera input + + + - -

GSM modem + for an additional fee - - -

Cancer formation

Other optional equipment

Easy filling of seed and fertilizer tanks from the ground with the Falcon 6 Compact and Falcon 7.2 Compact models.

High-intensity LED lights for comfortable work in low visibility.

Solution for tractors with insufficient hydraulic system parameters.

| FALCON COMPACT 3 | FALCON COMPACT 4 | FALCON COMPACT 4 FIX | FALCON COMPACT 6 | FALCON COMPACT 7.2 | |

|---|---|---|---|---|---|

| Working width, mm | 3 000 | 4 000 | 4 000 | 6 000 | 7 200 |

| Transport width, mm | 3 000 | 3 000 | 4 000 | 3 000 | 3 000 |

| Transport height, mm | 2 800 | 2 800 | 2 800 | 2 800 | 2 800 |

| Total length, mm | 7 000 | 7 000 | 7 000 | 7 000 | 7 000 |

| Working depth, mm | 0─100 | 0─100 | 0─100 | 0─100 | 0─100 |

| Seed hopper capacity, l | 2 800 | 2 800 | 2 800 | 4 000 | 4 000 |

| Seed hopper capacity with fertilizer (capacity ratio 40:60), l | 4 000 | 4 000 | 4 000 | 5 000 | 5 000 |

| Loading height, mm | 2 600 | 2 600 | 2 600 | 2 600 | 2 600 |

| Dimensions of bunker filling openings, mm | 520x1920 | 520x1920 | 520x1920 | 520x1920 | 520x1920 |

| Seeding discs, pcs. | 24 / 20 / 18 | 32 / 26 / 24 | 32 / 26 / 24 | 48 / 40 / 36 | 58 / 48 / 43 |

| Distance between rows, mm | 125 / 150 / 167 | 125 / 150 / 167 | 125 / 150 / 167 | 125 / 150 / 167 | 125 / 150 / 167 |

| Seed disc pressure force – oscillating (adaptive), kg | 15–120 | 15–120 | 15–120 | 15–120 | 15–120 |

| Seeding disc pressing force – according to parallelogram suspension, kg | 15–150 | 15–150 | 15–150 | 15–150 | 15–150 |

| Pressing force of the fertilizer insertion discs, kg | up to 200 | up to 200 | up to 200 | up to 200 | up to 200 |

| Number of discs, pcs. | 23 | 31 | 31 | 46 | 55 |

| Diameter of sowing discs, mm | 355 | 355 | 355 | 355 | 355 |

| Productivity, ha/hour | 3─4.5 | 4─6 | 4─6 | 6─9 | 7.2─11.3 |

| Tractor power, kW/HP | 80─110 110─150 | 95─130 130─180 | 95─130 130─180 | 120─185 160─250 | 145─205 200─280 |

| Working speed, km/h | 10─20 | 10─20 | 10─20 | 10─20 | 10─20 |

| Maximum working slope, ° | 6 | 6 | 6 | 6 | 6 |

| Wheel size - transport, 420/55 R 17 | 7,5 * 16 | 7,5 * 16 | 7,5 * 16 | 7,5 * 16 | 7,5 * 16 |

| Hydraulic connections / pressure, bar | 2 / 210 | 2 / 210 | 2 / 210 | 2 / 210 | 2 / 210 |

| Number/type of hydraulic connections | 4 / ISO 12.5 | 4 / ISO 12.5 | 4 / ISO 12.5 | 4 / ISO 12.5 | 4 / ISO 12.5 |

| Non-pressurized return line (max. 5 bar) | 1 / ISO 20 | 1 / ISO 20 | 1 / ISO 20 | 1 / ISO 20 | 1 / ISO 20 |

| Hydraulic fan oil flow, l/min. | 30─40 | 30─40 | 30─40 | 30─40 | 30─40 |

| Machine control oil flow, l/min. | 30 | 30 | 30 | 30 | 30 |

| Electrical requirements | 12V DC / 25─55A | 12V DC / 25─55A | 12V DC / 25─55A | 12V DC / 25─55A | 12V DC / 25─55A |

| Towing | TPH cat. 2 and 3 | TPH cat. 2 and 3 | TPH cat. 2 and 3 | TPH cat. 2 and 3 | TPH cat. 2 and 3 |

| Machine weight without fertilization system, kg | 4 100 | 5 600 | 4 600 | 7 500 | 8 500 |

| Machine weight with fertilization system from, kg | 4 300 | 5 800 | 5 300 | 7 800 | 8 900 |

FARMETH – the largest manufacturer of agricultural machinery for tillage and sowing in the Czech Republic. The company, founded in 1992, is growing rapidly and devotes much attention and investment to the development of new technologies.

FARMETH agricultural equipment manufactured by this manufacturer must meet the strictest standards of work quality, reliability and durability. All equipment of this manufacturer 36 months warranty provided.

Products and technologies are developed in close collaboration with customers, research institutes and universities. FARMETH The products feature unique technological solutions, some of which are patented. The company seeks not only to improve product quality and create added value, but also to improve production technologies, productivity, and improve occupational safety and environmental protection.

FARMETH The brand is focused on high-quality products and high value. Major investments in modern production management ensure further quality improvement and more efficient production. The goal is to increase the added value of products and strengthen their competitiveness in all markets.

You can rent this equipment!

We offer the possibility of this technique rent for a day, a week or any other time you want. For rental conditions or other land cultivation, sowing, fodder preparation, and fertilization equipment, please contact our technical department.