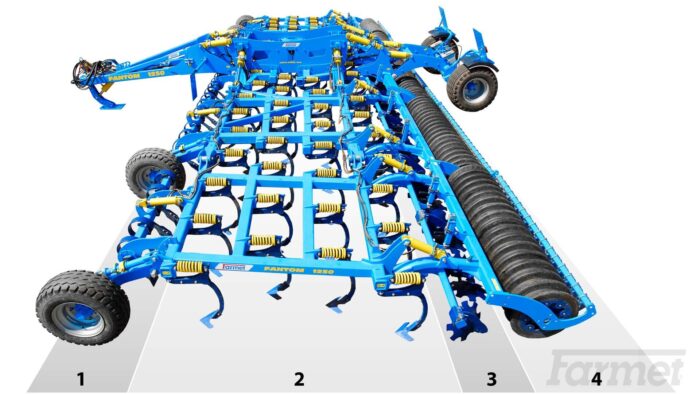

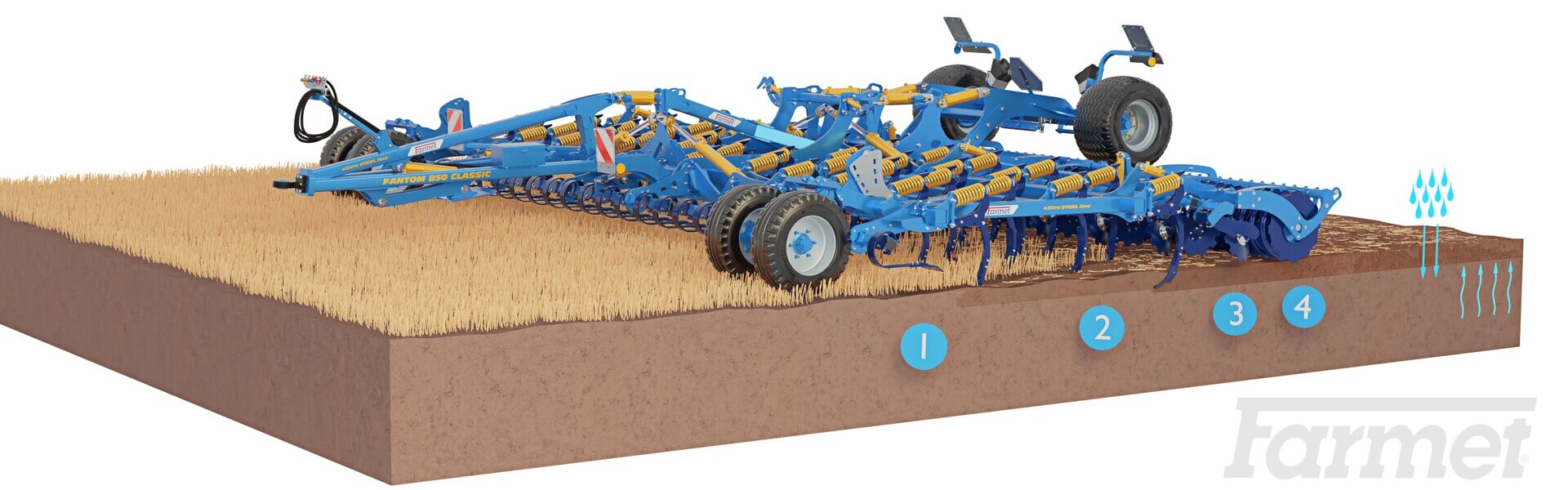

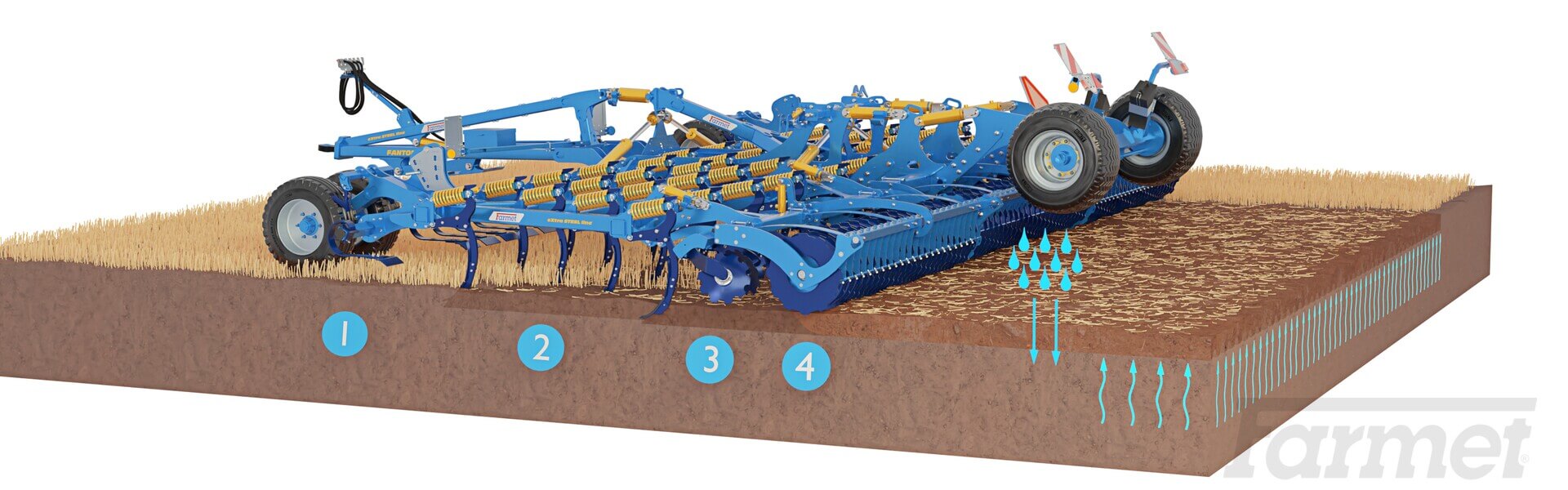

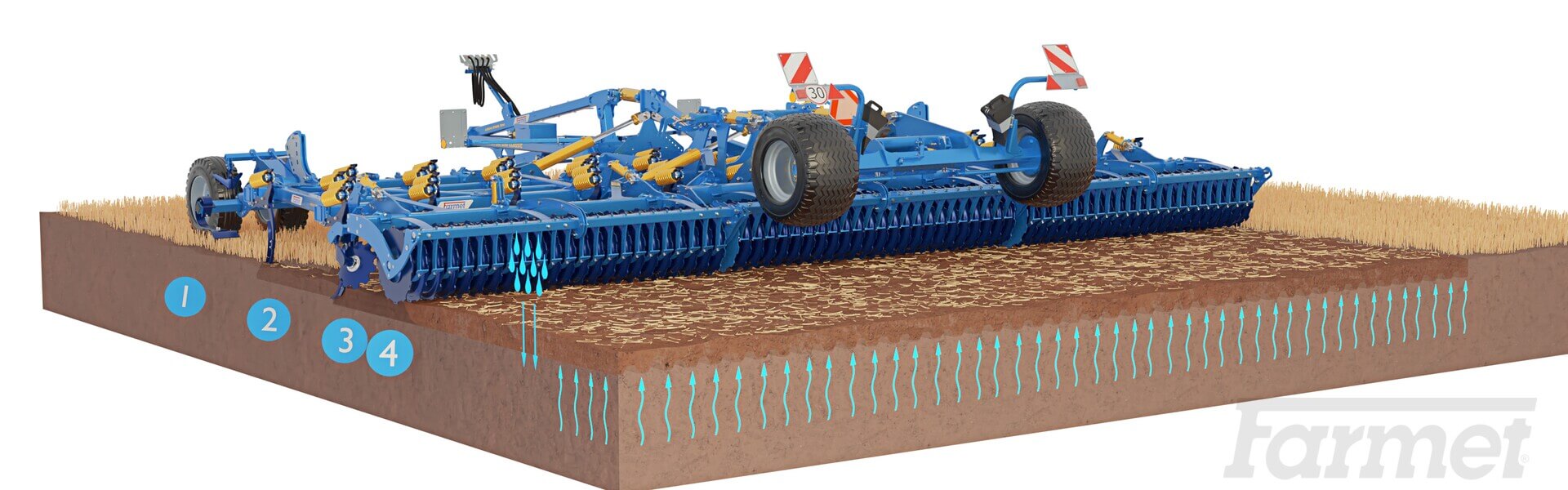

4-row tine cultivator with intensive soil cultivation up to 15 cm depth and excellent mixing

Intensive soil cultivation up to 15 cm depth with excellent mixing

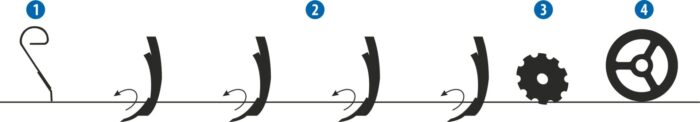

1. Soil surface leveling zone. Suitable for preparing the soil for sowing.

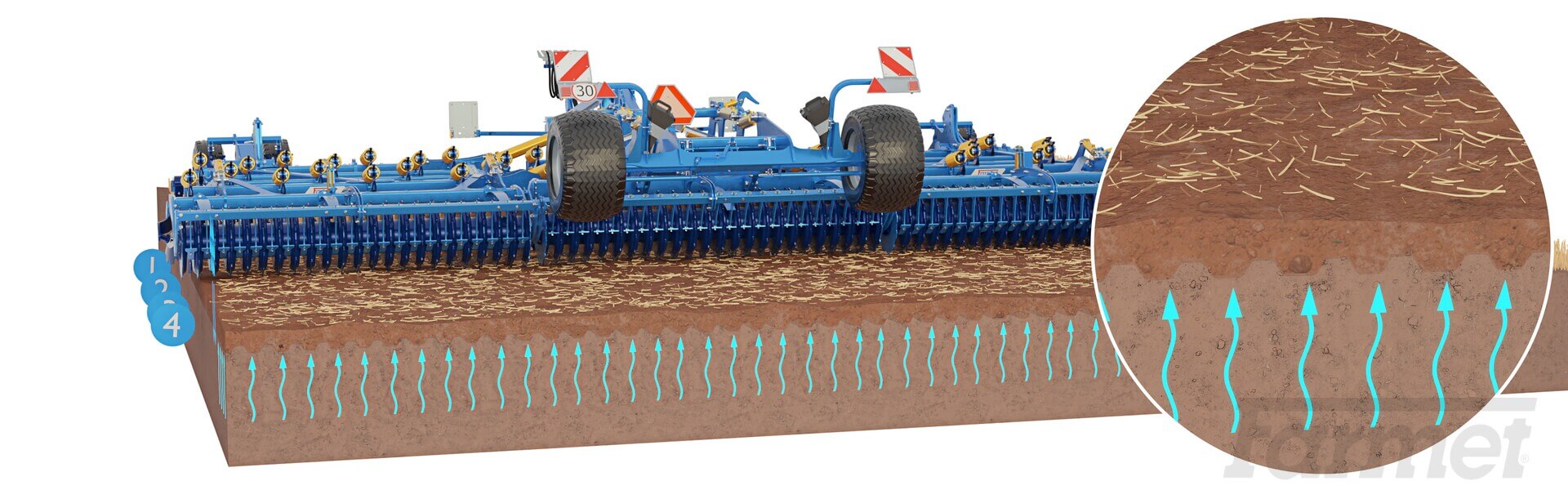

2. Loosening zone. Loosening depth 4–15 cm. The optimally shaped tines, arranged in four rows with a small final gap between the tines, ensure particularly good loosening of the entire area and intensive mixing of soil and plant residues.

3. Surface leveling zone. Leveling discs also improve the incorporation of crop residues.

4. Clump breaking and soil compaction zone. Optimal soil compaction ensures good water infiltration and soil moisture retention. The rollers are easily removable, so you can work without them.

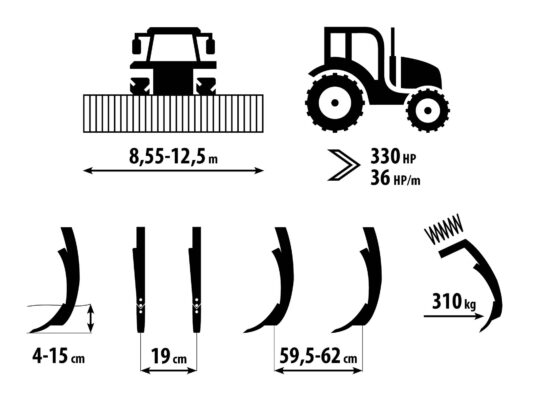

Trailed 4-row Fantom CLASSIC tine cultivator with low draft requirement and adjustable with a cultivation depth of up to 15 cm.

High quality and efficient work

- Large working speed – up to 12 km/h.

- Low traction requirement and excellent soil mixing due to optimized tine design.

- Precise deep cultivation with optimal soil compaction.

- Excellent tine penetration into the soil.

- Low maintenance working elements with carbide plates to ensure minimal wear.

4. Optional rear rollers for various working conditions. 4. Optional rear rollers for various working conditions.

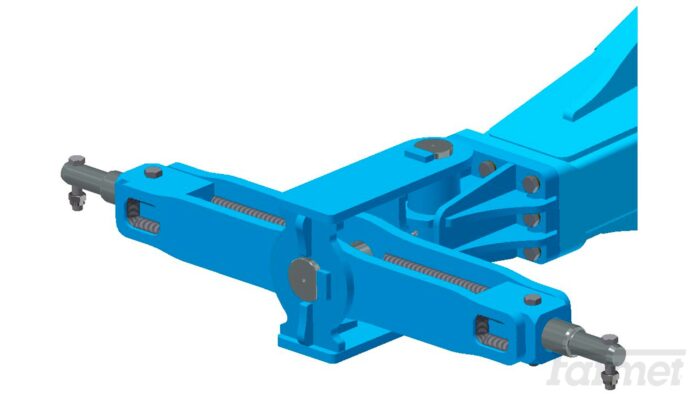

Intensive and fine cultivation is ensured 190 mm spacing between tinesThe tines have a spring-loaded protection with extremely high release force of 310 kg at the end of the tine. The scythe is characterized by constant working depth even in the most difficult conditions.

Due to minimal adjustment and lubrication points Operation and further maintenance are very simple and easy for every operator to perform.

Full-surface stubble cultivationFantom 850 Classic

Fantom 1250 Classic

Intensive and fine cultivation

Easy to use

A cleverly designed machine

Using V-shaped tines, stubble is cut to a depth of 15 cm over the entire area.

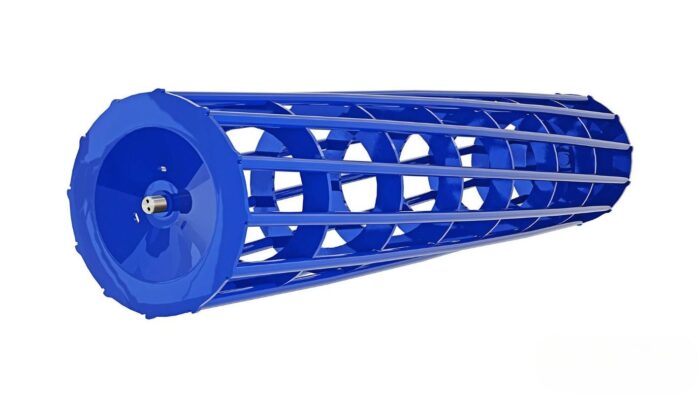

Tubular roller TRS

Diameter – 586 mm

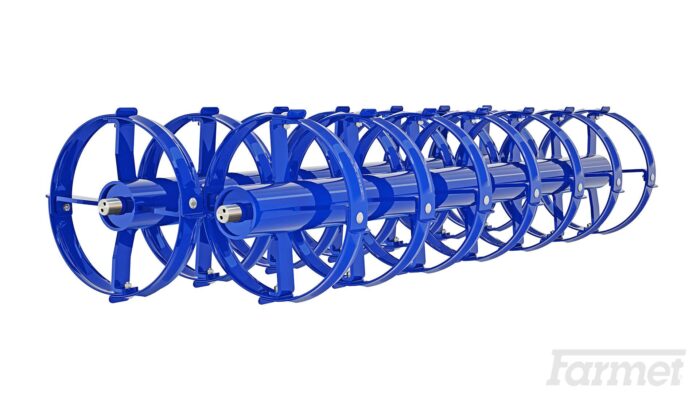

Diameter – 520/520 mm

Diameter – 600 mm

The correct selection of the rear roller type, which significantly contributes to the final quality of cultivation, is of utmost importance. The soil is repeatedly compacted by the roller, while at the same time breaking up clods and leveling the surface. The type of roller is selected taking into account the type of soil and the planned use of the machine.

50 MULTICARBIDE Coulter width – 50 mm 50 CARBIDE Coulter width – 50 mm 40 CARBIDE with interchangeable blades Coulter width – 280 mm Fork 230 mm Coulter width – 230 mm Left inclined tine sliver

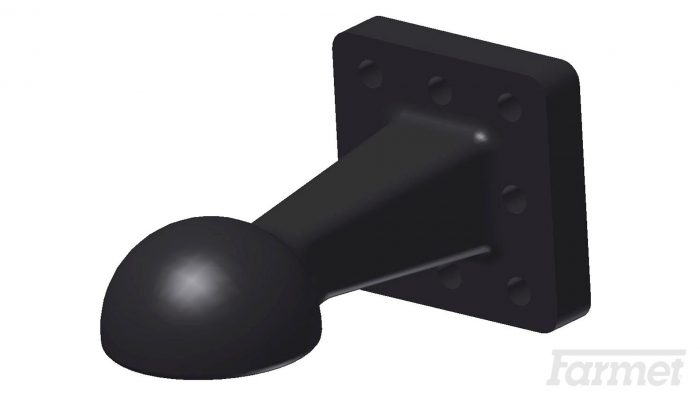

Swivel towing eye Ø 50 mm, Ø 70 mm Pin set for TPH hitch system, category 4 TPH category 3 K80 Ø 80 mm.

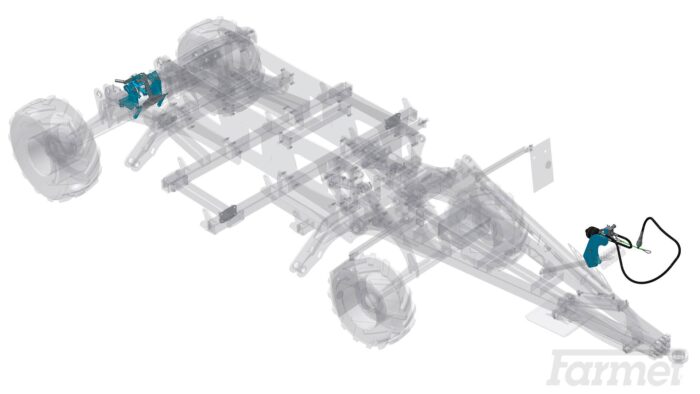

Electro-hydraulic flow distributor Hydraulic brakes Depth support wheel set Flexi-cutRollers

Diameter – 600 mm

Weight – 100 kg/m

Diameter – 540/540 mm

Weight – 200 kg/m

The LTX roller cannot be used with the Fantom 850 CLASSIC model.

Weight – 220 kg/m

Weight – 165 kg/m

Weight – 175 kg/m

Weight – 180 kg/m

Tubular TRS roller Double ring DRR roller Double smooth roller DFR LTX roller SDR disc roller V-shaped VR roller Double roller DVR

Crushing ●●○○ ●●●○ ●●●○ ●●○○ ●●●○ ●●●○ ●●●○

Compaction ●●●○ ●●●● ●●●● ●●●● ●●●● ●●●● ●●●●

Depth support ●●●○ ●●●● ●●●● ●●●● ●●●● ●●●● ●●●●

Resistance to clogging ●○○○ ●●●● ●●●● ●●●○ ●●●○ ●●●● ●●●●

Suitability for rocky soils ●●●○ ●●●○ ●●●○ ●●●○ ●●●○ ●●●○ ●●●○

Suitability for wet soils ●○○○ ●●●● ●●●● ●●●● ●●●● ●●●● ●●●●

Suitability for heavy soils ●●○○ ●●●● ●●●● ●●●● ●●●● ●●●● ●●●●

Suitability for medium soils ●●●○ ●●●● ●●●● ●●●● ●●●● ●●●● ●●●●

Suitability for light soils ●●●● ●●●● ●●●● ●●●○ ●●●○ ●●●● ●●●●

Working tools

Coulter body hardness – up to 55 HRC

Widia plate hardness – up to 92 HRA

Coulter service life – +400–600 %

Coulter thickness – up to 55 HRC

Coulter body hardness – up to 92 HRA

Hardness of the weld – up to 60 HRC

Coulter service life – +400-600 %

Coulter body width – 43 mm

Coulter thickness – 6 mm

Coulter body hardness – up to 55 HRC

Carbide plate hardness – up to 92 HRA

Coulter thickness – 8 mm

Coulter body hardness – up to 55 HRCTowing

Other optional equipment

Divides one tractor hydraulic circuit into three separate circuits.

| Phantom 650 CLASSIC | Phantom 850 CLASSIC | Phantom 1250 CLASSIC |

|

|---|---|---|---|

| Working width, mm | 6 300 | 8 550 | 12 250 |

| Transport width, mm | 3 000 | 3 000 | 3 000 |

| Transport height, mm | 3 650 | 4 000 | 4 000 |

| Total length, mm | 8 000 | 8 700 | 8 200 |

| Working depth, mm | 40–150 | 40–150 | 40–150 |

| Tines, pcs. | 33 | 45 | 64 |

| Distance between tines, mm | 190 | 190 | 190 |

| Number of tine rows, pcs. | 4 | 4 | 4 |

| Distance between rows, mm | 595–620 | 595–620 | 595–620 |

| Fork pressure force, kg | 310 | 310 | 310 |

| Frame clearance, mm | 570 | 570 | 570 |

| Productivity, ha/hour | 4.4–7.2 | 6.8–10.2 | 10.0–15.0 |

| Tractor power, kW/HP | 200–300 270–410 | 245–370 330–500 | 330–440 450–675 |

| Working speed, km/h | 8–12 | 8–12 | 8–12 |

| Maximum working slope, ° | 6 | 6 | 6 |

| Hydraulic connections/pressure, bar | 5 / 200 | 5 / 200 | 5 / 200 |

| Number/type of hydraulic connection pairs | 8 / ISO 12.5 | 8 / ISO 12.5 | 8 / ISO 12.5 |

| Towing | TPH category 3; pin Ø 50, 70 mm; ball joint K80 | TPH category 3; pin Ø 50, 70 mm; ball joint K80 | pin Ø 50, 70 mm; ball joint K80 |

| Weight, kg | 7 000 | 8 900 | 12 400 |

FARMETH – the largest manufacturer of agricultural machinery for tillage and sowing in the Czech Republic. The company, founded in 1992, is growing rapidly and devotes much attention and investment to the development of new technologies.

FARMETH agricultural equipment manufactured by this manufacturer must meet the strictest standards of work quality, reliability and durability. All equipment of this manufacturer 36 months warranty provided.

Products and technologies are developed in close collaboration with customers, research institutes and universities. FARMETH The products feature unique technological solutions, some of which are patented. The company seeks not only to improve product quality and create added value, but also to improve production technologies, productivity, and improve occupational safety and environmental protection.

FARMETH The brand is focused on high-quality products and high value. Major investments in modern production management ensure further quality improvement and more efficient production. The goal is to increase the added value of products and strengthen their competitiveness in all markets.