2000 liter pressure hopper for various types of seeds or fertilizers

One of the most versatile seed and fertilizer hoppers on the market

Reliable pressure hoppers that can be used with precision seeding, belt and traditional seed drills, fertilizer applicators, cultivators, hoes, harrows, etc. implements.

- High seed and fertilizer dosing accuracy

- Dosing of microgranular products

- Compensation hopper with reloading to the rear hopper of the drill

- Depending on the configuration, one or two compartments

- Strong and lightweight frame made of high-strength steel

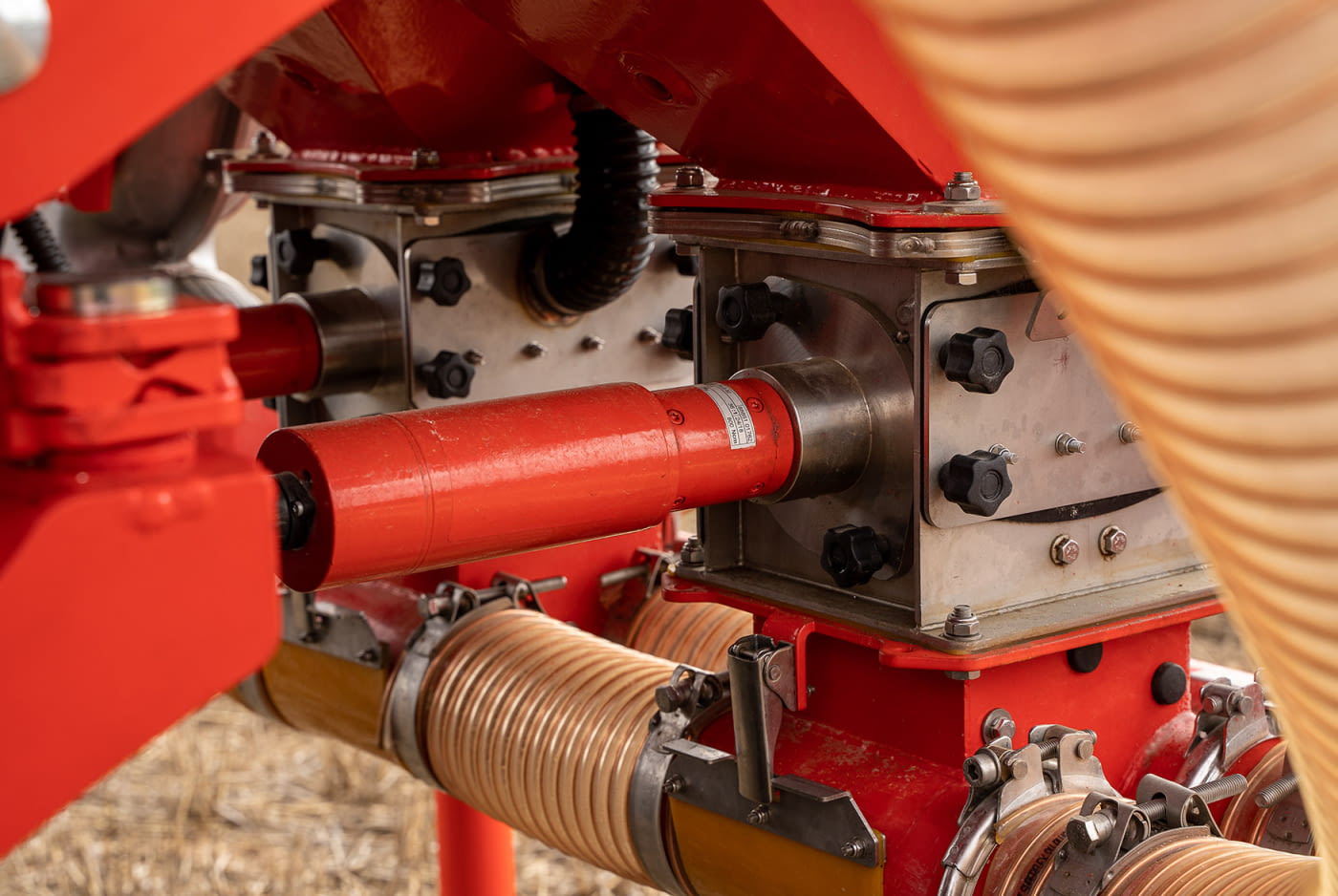

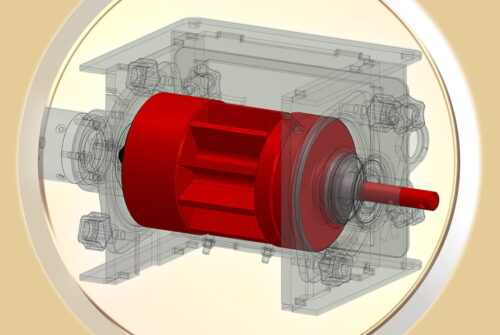

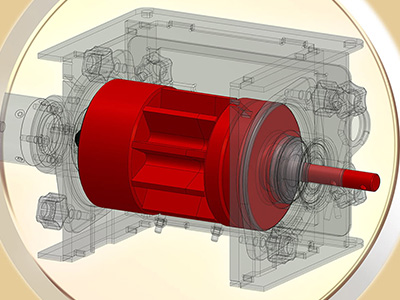

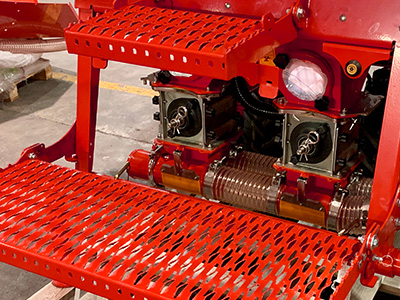

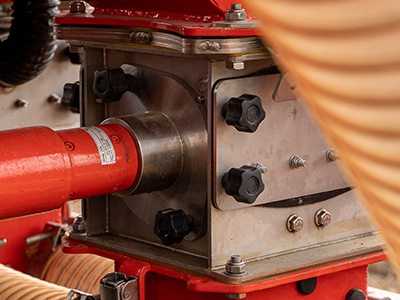

- Stainless steel dispenser with replaceable modular coils and electric drive

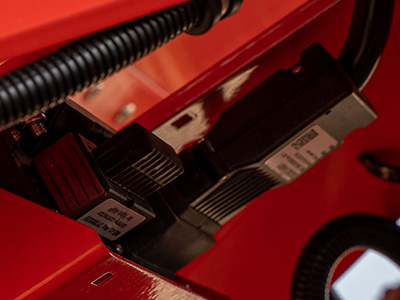

- Two metering control systems: ISOBUS and non-ISOBUS

- Accurate and simple seed metering calibration kit

- Easy product filling using the convenient step-on platform

- Work and transport lighting

- Product level sensor

- Support wheels

What are the advantages of a pressurized bunker?

Comparing a pressure bunker with a traditional bunker, we can highlight several advantages:

- Lower tractor fuel consumption

- Lower hydraulic oil flow requirement

- Dosing higher seed and fertilizer rates

- Lower noise level during operation

- Better product preservation due to hermetic sealing

- More consistent dosing rate regardless of hopper filling

- More efficient hopper emptying

Dosing of all types of seeds and granular fertilizers. The dosing reel can be changed in a few seconds.

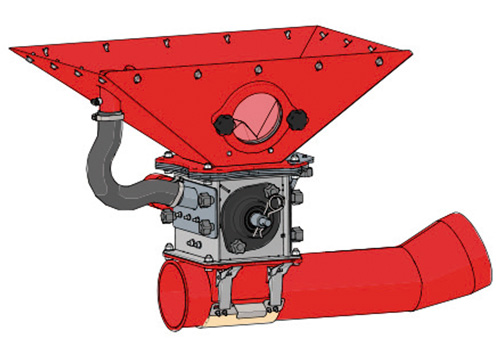

The pressurized distribution system provides a uniform air flow from the front hopper to the rear implement.

The modern hopper design allows for quick, accurate and easy access and cleaning of the inner part of the hopper.

Easily accessible dispensers make calibration extremely simple and quick

Insertion of mineral fertilizers into pneumatic seed drills

Incorporating mineral fertilizers into precision seed drills

You can use the hopper not only with seed drills, but also with hoes, cultivators, harrows and other tillage implements!

Aura dispenser with electric drive made of stainless steel Aura communicates with the drill and tractor via ISOBUS connection 50/50 split hopper allows dosing of two different products Thanks to its compact shape, Aura does not obstruct visibility from the tractor cab during work and transport. Various modular coils available for different dosing levels and productsModular dispenser

Even air flow

Convenient design

Easy calibration

Easy adaptability

Built to last

ISOBUS connection

Several products

Good visibility

Modular coils

Dosing of two products

ISOBUS ECU

Various modular coils

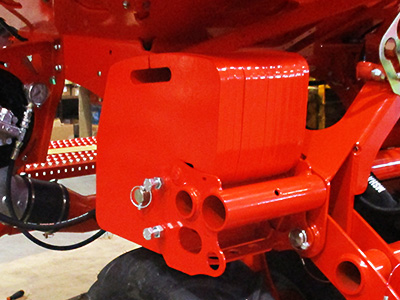

Hydraulic drive fan

Convenient platform for climbing

Front support wheels

Hopper level sensor

Product calibration button

Weights

Hydraulic system pressure gauge

Internal bunker pressure gauge

Two dispensers

Stainless steel dispenser

Transport and LED work

Ability to choose the desired control

body

lights

terminal

Dispenser with reel,

Dispenser with reel,

Dispenser with reel,

Dispenser with reel,

Double dispenser with coils,

Double dispenser with coils,

Double dispenser with coils,

Screw feeder,

Double-barrel dispenser,

1 outlet Ø100 mm or Ø120 mm

1 outlet Ø80 mm

2 outputs Ø80mm

2 outlets Ø100 mm

1 outlet Ø80 or Ø120 mm

2 outputs Ø80mm

2 outputs Ø100mm

1 outlet Ø80 mm

2 outlets Ø80 mm

| AURA 2000 | |

|---|---|

| Capacity, l | 2000 |

| Width, mm | 2300 |

| Length, mm | 1690 |

| Height, mm | 1725 |

| Height with outrigger wheels, mm | 1900 |

| Metering drive type | Power plant |

| Weight, kg | 450 |

| Weight with additional weights, kg | 900 |

| Weight with additional weights and supports wheels, kg | 1110 |

| Fan drive | Hydraulic or mechanical from the tractor PTO |

| Hydraulic oil flow, l/min | 15 |

| Fan pressure control | Analog pressure gauge, standard equipment |

| Number of hydraulic connections | 1 + free return (maximum pressure 1 bar) |

| Towing category | Cat. 3 |

| Loading opening, cm | 147 x 82 |

| Loading height without wheels, mm | 1725 |

| Speed input | Optional equipment: 7-pin, GPS |

| Work and transport lights | Standard equipment |

| Calibration kit | Standard equipment |

| Controller/Monitor | Optional equipment: with or without ISOBUS |

| Hopper pressure control | Analog pressure gauge, standard equipment |

| Hopper level sensor | Standard equipment |

| Tractor requirements | Front three-point suspension Front hydraulic control (1 connection + free return) Electrical connection DIN/ISO: 1724 |

AGRICULTURAL MACHINERY SOLÀ, SL was founded 50 years ago. The factory is located in Calaf, Barcelona province, Spain.

Having started by selling agricultural equipment and gaining experience, the company began to design and manufacture mechanical seed drills, which were renowned for their robust construction and reliability.

SOFA The seed drills are manufactured using many years of experience, with special attention to strength, reliability and durability. There are currently over 20,000 used seed drills on the market.