Reliable mixer-distributors with a single mixing auger capacity of 7.5 -16.5 m³

New generation 7.5 m3 – 16.5 m³ capacity mixer-distributors

High quality and efficient work

- 7.5 – 16.5 m³ capacity.

- One charge feeds 30-120 cows.

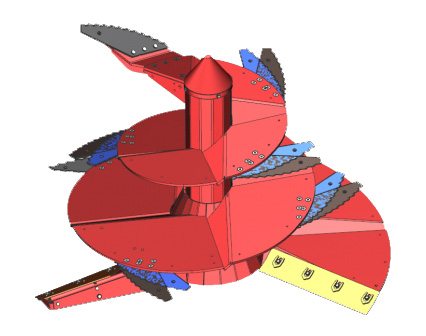

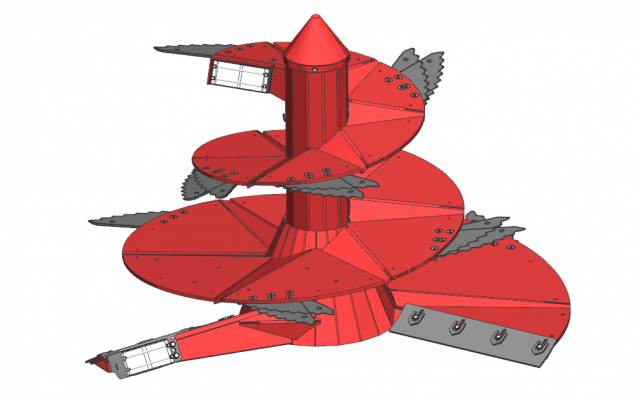

- One Copper2 mixing screw.

- Unique mixer shape ensures smooth and fast mixing process.

- Patented solution – as the herd grows, the mixer-distributor can be easily enlarged by adding extensions.

- 180 mm or 360 mm elevations.

- Various unloading options.

- Electronic scales.

- Creating a uniform and optimal diet.

The mixer capacity has neither internal nor external corners, and the feed is mixed extremely quickly and thoroughly.

One Copper2 The mixing screw mixes extremely quickly and evenly:

Ring from transfusion

180 mm elevations

360 mm elevations

Unique faucet shape

One mixing screw

Magnet system

Ring from transfusion and promotions

Additional benefits of Verti-Mix when choosing a spreading equipment. Calling the roller Straw spreader Feed roller

Direct control from the tractor

Bowden cable control

Electric control

PTM HL 50 – programmable weighing system without data transmission

PTM Advance Super USB – programmable weighing system with data transmission

PTM AV 70 – remote control Suitable for PTM HL 50 and PTM Advance Super USB weighing systems.

Feed unloading according to needs

Calling

Management

Weighing system

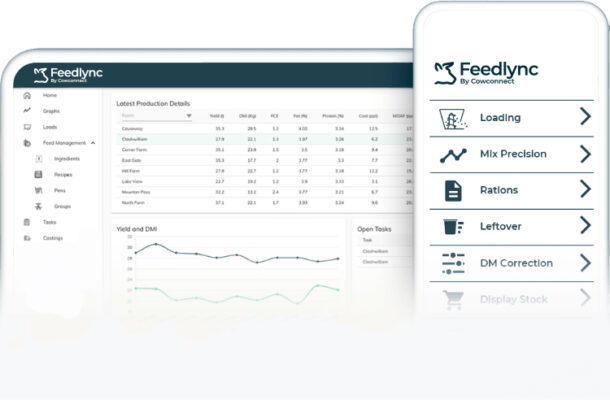

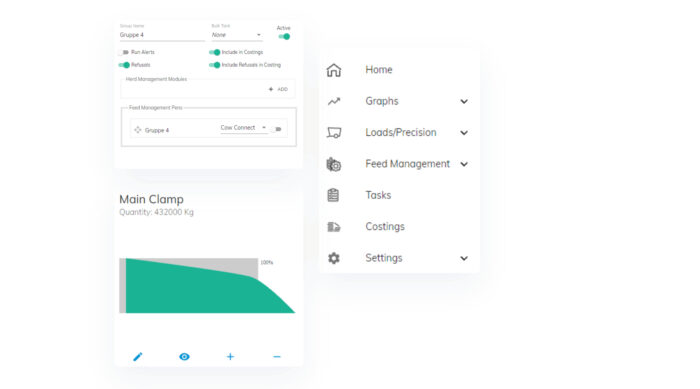

A unique cloud-based solution that will help you accurately track, manage, and otherwise streamline feeding operations.

Feedlync seamlessly integrates with your farm's external systems and automatically imports milk yields and cow numbers. Stay connected to your farms and feeding process, get automated, reliable data instantly, work proactively with multiple farms by viewing their data. Change rations, add or remove ingredients, manage pens and groups remotely. Feedlync integrates with several external systems to provide accurate and detailed costing. Feedlync has a lot of features that help you save time and work more efficiently

Active monitoring Track feed consumption, price per liter and more. Real-time data exchange Get data to your app in real time from anywhere in the world. Weather corrections Adjust the feeding plan to ensure that weather conditions do not affect milk yield. Low stock alerts You will be notified when the stock of silage or other feed reaches a defined minimum quantity. Farm data interfaces Feedlync integrates with other systems, saving you time and money. Saved reports Change saved recipe data to avoid feed waste and increase profits. Cloud backup Copies of your data are automatically saved, without the risk of losing anything. Charts and analysis The app helps you clearly see and understand the collected data and costs. Animal health Accurate feeding data provides the best understanding of your animals' health.Feedlync intelligent feeding management system

Router

Feedlync integrates with your existing systems

Data at your fingertips

Direct monitoring of farm expenses

But that's not all.

| 951 VM | 1251 VM | 1451 VM | 1651 VM | |

|---|---|---|---|---|

| Useful capacity, m³ | 7,5 | 8,5 | 9,5 | 10 | 11 | 12,5 | 13.5 | 13,5 | 15 | 16,5 |

| Heights, mm | - | 180 | 360 | - | 180 | 360 | - | - | 180 | 360 |

| Length with front cross conveyor, mm | 5,300 | 5,500 | 5,750 | 5,750 |

| Length with rear cross conveyor, mm | 4,900 | 5,040 | 5,170 | 5,170 |

| Length without cross conveyor, mm | 4,650 | 4,870 | 5,100 | 5,100 |

| Width with cross conveyor, mm | 2,160 | 2,280 | 2,420 | 2,420 |

| Width with one-sided unloading, mm | 2,260 | 2,380 | 2,520 | 2,520 |

| Width with double-sided unloading, mm | 2,360 | 2,480 | 2,620 | 2,620 |

| Height, mm | 2 310 | 2 490 | 2 670 | 2 720 | 2 900 | 3 080 | 2,920 | 2 920 | 3 100 | 3 280 |

| Total weight, kg | 7,000 | 9,000 | 11,400 | 11,400 |

| Net weight with cross conveyor, kg | 3 200 | 3 260 | 3 300 | 3 800 | 3 860 | 4 150 | 4,840 | 4 840 | 4 900 | 5 000 |

| Intersection, mm | 1,510 | 1,630 | 1,740 | 1,740 |

| External width between wheels, mm | 1,780 | 2,040 | 2,230 | 2,230 |

| Unloading height, mm | 750 | 870 | 740 | 740 |

| Wall thickness, mm | 8 | 8 | 8 | 8 |

| Bottom thickness, mm | 18 | 20 | 20 | 20 |

| Wheels | 10.0/75-15.3 | 400/60-15.5 | 8.15-15 | 8.15-15 |

| POWER NEED | ||||

| Without 2-speed gearbox (26 rpm), kW/HP | 26/35 | 28/39 | 31/42 | 37/50 | 38/52 | 41/56 | 53/72 l 58/79 | - | - | - |

| With 2-speed gearbox (14.4/26 rpm), kW/HP | 19/25 | 21/28 | 22/30 | 26/35 | 28/38 | 29/40 | 33/45 | 36/49 | - | - | - |

| Without 2-speed gearbox (30 rpm), kW/HP | 32/44 | 35/47 | 37/51 | 49/67 | 51/69 | 54/73 | 63/85 | 69/94 | 65/88 | 71/96 | 78/106 |

| With 2-speed gearbox (16.7/30 rpm), kW/HP | 23/32 | 25/34 | 27/37 | 35/47 | 37/50 | 41/56 | 45/61 | 49/67 | 40/54 | 44/60 | 48/65 |

| Without 2-speed gearbox (23 rpm), kW/HP | - | - | - | - | - | - | - | - | - | 54/73 | 59/80 | 65/88 |

| With 2-speed gearbox (12.8/23 rpm), kW/HP | - | - | - | - | - | - | - | - | - | 33/45 | 36/49 | 40/54 |

A family-run company based in northern GermanyB. Strautmann & Söhne GmbH u. co. KG"has been around for over 85 years.

STRAUTHMANN The factory has developed a wide range of products, especially well suited for livestock farms. The company can offer silage handling equipment for various purposes: silage buckets, silage cutters and silage block cutters for easy silage removal.

STRAUTHMANN Silage block and feed transport trailers have been ensuring fast and easy feed supply for several decades. We also manufacture trailed and self-propelled feed mixers - perfect for preparing physiologically ideal animal feed.

For optimal feed quality, STRAUTHMANN presents grass silage handling equipment. In order to maintain the best quality of feed, the grass loaded into the self-loading trailer is gently but optimally chopped. Customers can purchase tri-axle trailers and dump trucks as well as trailers for convenient feed transportation. Also, manure and universal shakers are available in various sizes. Thus, by creating a high-quality and diverse product offering, STRAUTHMANN the company becomes a competent partner for the farmer.