Professional solution for comprehensive pasture management – suitable for use with 40-130 HP tractors

Ideal mulch quality and organic matter crushing

Combined device with an integrated biostimulant spraying system, which is specifically designed to promote the mineralization of straw, animal manure and plant residues

- Designed for tractors with a power of 40–130 HP.

- The latest generation shredder with the MU-Vario® system, which ensures perfect cutting and efficient shredding.

- Hardened M-shaped hammers are made of special steel.

- Shark fin shredding belt with "shark fins" for even material movement (patented by Müthing).

- Double spraying system – biostimulants are spread before and after shredding.

- Stainless steel tanks – 220 or 440 liters.

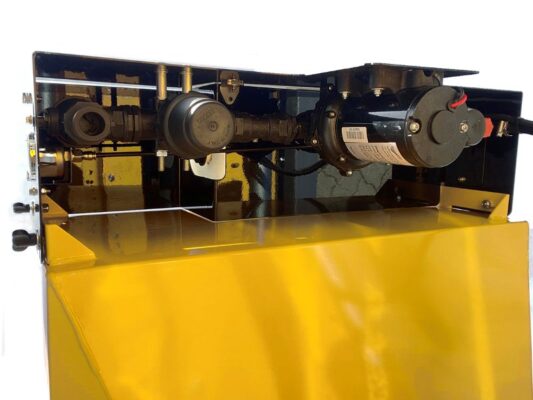

- Electric pump with suction and pressure filters.

CombiMulcher mulcher features

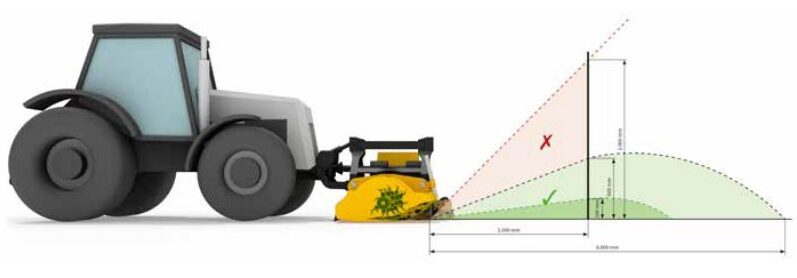

Stone throwing certificate issued by TÜV Nord

Müthing, in cooperation with TÜV NORD, has successfully tested all mulchers with a working width of up to 3.2 m for objects thrown during operation. As a result, safety distances are reduced to 2 m on the sides and 8 m in front and behind the machine.

MU-Vario® system

Complete control over working conditions. Optimal intake, adjustable body shape, adjustable PTO speed, infinitely adjustable bedknife and pivoting support roller allow easy adaptation to any field conditions.

Shark fin shredding strips with shark fins

The system ensures even shredding of all plant residues: longer materials are returned for additional processing, and once properly shredded, they immediately move on.

M-DuraX hammers

Müthing M-DuraX mulcher hammers are durable, high-performance and perfect for both grass cutting and shrub chopping. Thanks to the boron alloy and hardening technology, they last up to 50 % longer, maintain high chopping quality and help save fuel.

Functionalities

- Spreading biostimulants before and after the mulching process.

- The spraying system ensures even coverage of all plants.

- Modular design of the spreading system.

- The compact pump module is mounted directly on the tank.

- The modular system can also be used as a separate unit for mulching.

- At the same time, grass residues and manure are chopped and a natural activator is spread.

- Helps form healthy soil microbiology, which suppresses weeds and helps create a resilient, dense and fast-growing turf layer.

- The composting device reduces the spread of parasites and rotting processes.

- The spraying function is particularly useful for pastures and horse stables, but can also be applied in agriculture.

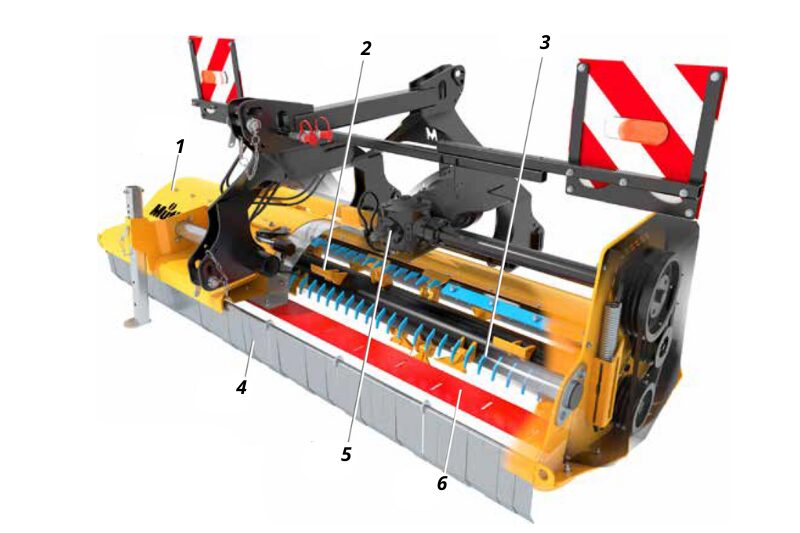

Every element contributes to making Müthing mulchers a reliable choice for your agricultural work. 1. Round body made of fine-grained steel with numerous profiled corners

2. Easily removable, bolted wearing parts

3. Exceptional shredding of crop residues even in difficult conditions

4. Special hardened steel spring safety valves

5. Drive unit All Müthing mulchers are equipped with a freewheel mechanism in the gearbox or hydraulic drive = Protection for both the mulcher and the drive system - maintenance-free, ensuring long-term operation. Maintenance Security All Müthing shredders are designed and manufactured in accordance with CE directives. They are also TÜV-approved in accordance with the ISO 17101-2 standard for optimal safety. 6. Adjustable front knife

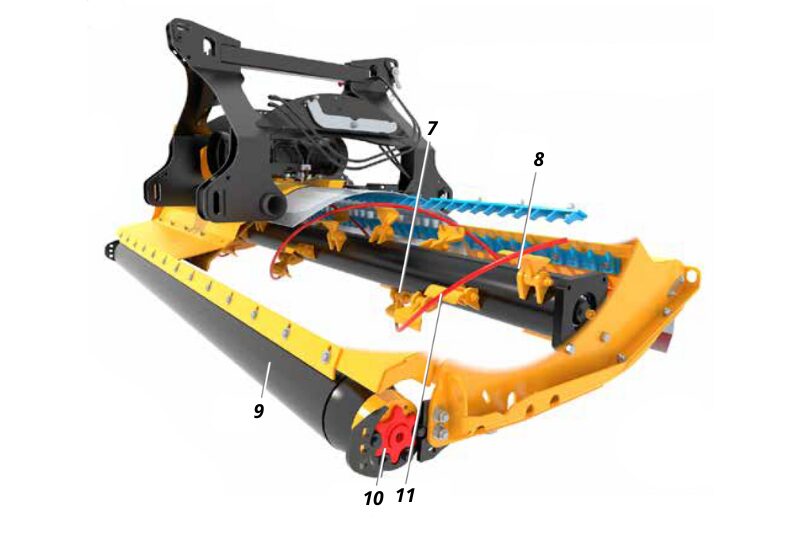

7. Weight balance – for stability Protects against damage when the working environment is full of obstacles and stones. 8. Double helix rotor Ensures high-quality cutting and shredding while consuming less power – more energy efficient. 9. Excellent surface copying and consistent cutting height The MU-M Vario and MU-PRO Vario models feature a patented pivoting support roller system, allowing for easy transition to single-operator operation. Mulch can be discharged both behind and in front of the support roller. Discharge before the support roller: Discharge behind the support roller:

10. Professional shredders with the unique Starinth® support roller bearing system (from model MU-L and above) Robust, long-lasting bearing system with multi-layer labyrinth sealing technology and a "floating" star-shaped axle integrated into the sidewall. 11. High quality DuraX M-shaped hammers with full support to the rotor

Tangential tool holders lift the rotor above obstacles, protecting it from imbalance A longer weld seam ensures a stronger connection of the brackets to the rotor and reduces the risk of them breaking.Müthing experience – your advantage

Müthing mulchers – certified by TÜV Nord for the distance of thrown objects

The MU-CombiMulcher mulcher also stands out with these advantages:

The result is ideal mulch quality and efficient shredding of organic residues.

The 3-point suspension frame integrated into the stainless steel tank ensures durability and convenient maintenance. The pump can be removed for maintenance and frost protection. Consists of an intake filter, electric pump, pressure filter and pressure regulating valve.

MU-Vario basic unit with stepless adjustment of the grinding intensity

Integrated 3-point suspension frame

Removable pump

Pump unit

Integrated water tank for flushing the system after use

Front and rear spray bars made of stainless steel

DuraX M-Shaped Hammers

The MU-Vario® system – complete control over working conditions. Optimal intake, adjustable body shape, adjustable PTO speed, infinitely adjustable knife and pivoting support roller allow easy adaptation to any field conditions.

Individual settings adapted to various agricultural crops: crushing rapeseed, cereals, corn stubble, as well as for crop and meadow maintenance and mulching abandoned fields.

The adjustable front knife allows you to easily adjust the chopping intensity to suit conditions and needs. Above: low crushing intensity

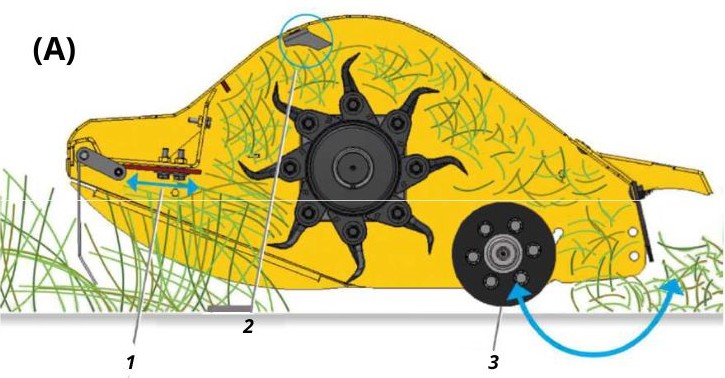

Mulch can be spread both in front of and behind the support roller (from MU-M series models). (Diagram A) Support roller turned forward:

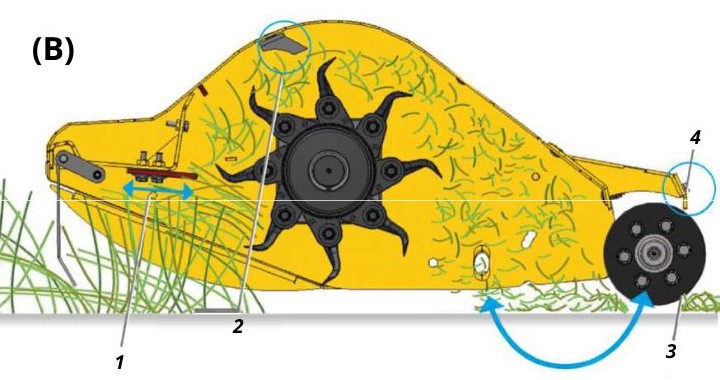

(Diagram B) Support roller turned to the rear:

The roller wiper (optional) ensures smooth shredding even in extremely wet conditions. The adjustable counter knife – only for the MU-Pro model – can also be optionally equipped with hydraulic adjustment. This allows you to conveniently control the chopping intensity directly from the tractor cab.MU-Vario system – for maximum working comfort and flexibility

Universal use – optimal treatment for all crops

Flexible adjustment of the grinding intensity

Below: high crushing intensityMU-Vario system operating concept:

1. The adjustable counter knife allows for infinitely variable adjustment of the chopping intensity to suit specific requirements.

2. Shark fin system:

3. The rotating support roller turns the mulcher into a versatile piece of equipment for year-round use

4. Sturdy support roller wiper

NEW: VARIO-SHIFT – hydraulic version

| CombiMulcher | 160 | 220 | 280 |

|---|---|---|---|

| Working width (cm) | 160 | 220 | 280 |

| External width (cm) | 178 | 238 | 297 |

| PTO (power take-off shaft) speed | 540 / 1 000 | 540 / 1 000 | 1 000 |

| Maximum tractor power (HP) | 90 | 90 | 130 |

| Weight (kg) | 640 | 840 | 1050 |

| Number of M-DuraX hammers | 14 | 18 | 24 |

| Rotor diameter (mm) | 140 | 160 | 180 |

| Support roller diameter (mm) | 140 | 140 | 195 |

| Number of V-belts | 3 | 3 | 3 |

Muthing German quality and reliability Wide selection Modern and sustainable solutions

This is a German manufacturer with over 120 years of experience in producing high-quality mulchers for agriculture, landscaping and gardens. The company began operations in 1898 and introduced its first mulchers in 1998. Today, it is a fourth-generation family business.

All Müthing implements are developed and manufactured in Germany, in accordance with high quality and safety standards. Much attention is paid to durability, practicality and resistance to intensive work. These mulchers are extremely efficient in shredding plant residues and adapt to various working conditions. Müthing, in cooperation with TÜV NORD, has carried out and successfully passed tests for the ejection of objects during work on all mulchers with a working width of up to 3.2 m. Therefore, when using a Müthing mulcher, you ensure maximum safety for yourself and those around you.

Müthing offers more than 1,500 mulcher models: mounted, foldable, mounted and trailed, for front, rear or side work. Available working widths range from 0.80 to 8.60 m. This variety of models allows every farm to find the most suitable solution.

The manufacturer works closely with scientists and customers from different countries. Solutions such as the MU-Vario system allow you to adjust the mulching as needed. At the same time, technology is being developed that contributes to insect protection and maintaining the ecological balance in the fields. Certified safety tests ensure safe work even near roads or settlements.