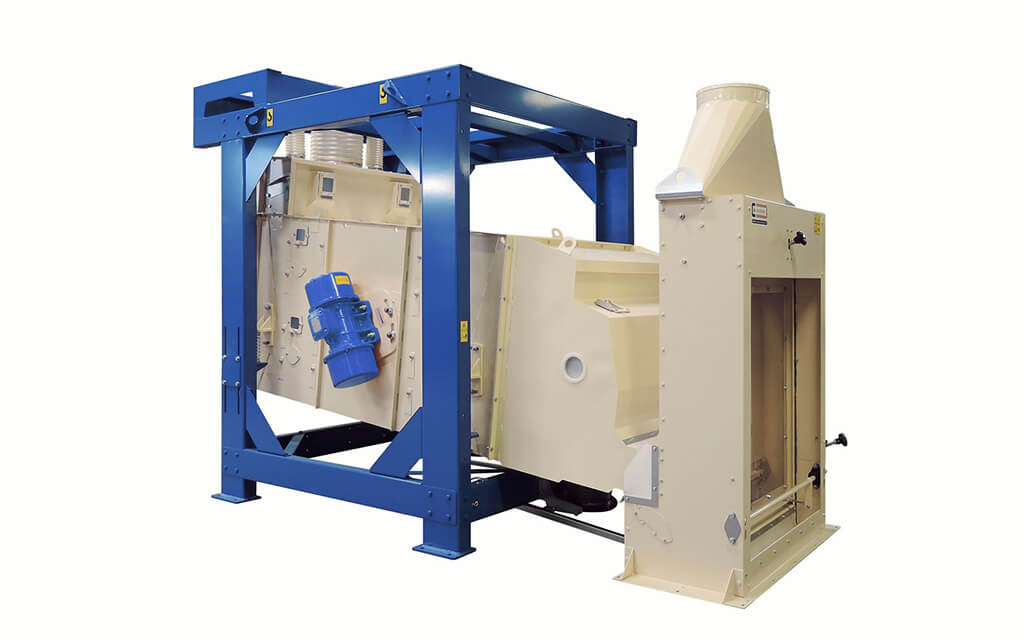

Vibrating modular screen cleaners for cleaning all agricultural crops from impurities

Modular cleaning JCM VibroMax with aspiration for cleaning and sorting all agricultural crops from impurities

High quality and efficient work

- Vibrating modular sieve cleaners for cleaning all agricultural crops from impurities.

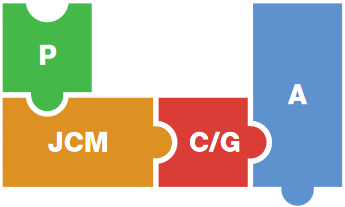

- The cleaning and aspiration channel can be supplemented with other modules.

- High-performance cleaning and high-quality sorting with woven screens with powerful aspiration.

- By selecting modules, you can configure the purifier to your needs.

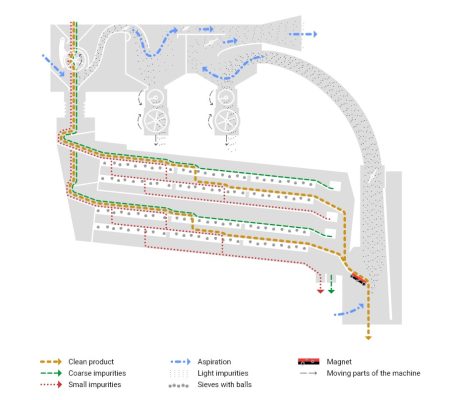

- The sieves are cleaned with the help of constantly moving rubber balls.

-

The capacity of the treatment plants is up to 300 t/h.

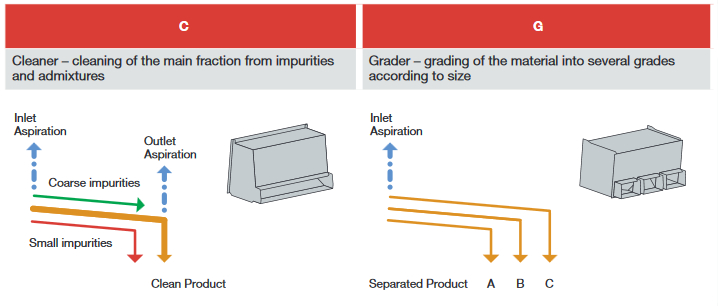

JCM VibroMax cleaners are tested for cleaning any seeds and are designed for use in areas where high productivity and continuous operation are required. The product being cleaned is sorted according to the size of the individual particles entering the separator (sieve separation) and according to different aerodynamic properties (air cleaning). JCM cleaners are designed for use in areas where high productivity and continuous operation are required.

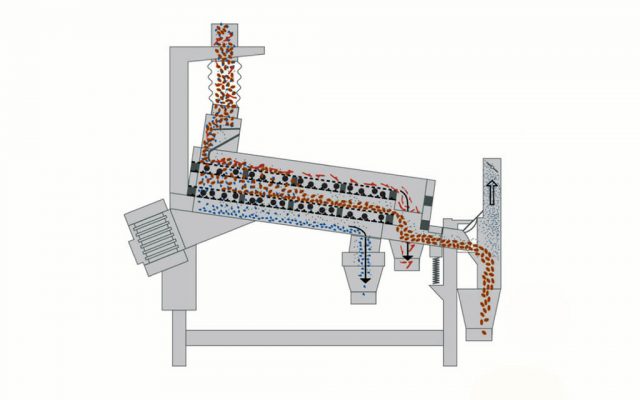

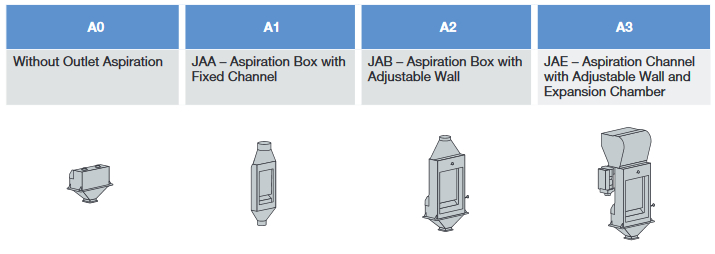

The aspiration channel separates fine impurities (dust, chaff, etc.). The adjustable aspiration channel wall allows you to set the optimal air channel. The integrated separator with fan and air recirculation reduce power requirements. The built-in permanent magnet captures iron-containing impurities. The closed housing design and constant air recirculation direct the dust to specially designated areas. The cleaning process takes place without dust being released into the environment. The cleaning and aspiration channel can be supplemented with other modules. For feed to the cleaning aspiration, a suction device can be added. P1 module: JAC – aspiration chamber for primary cleaning without rotary feeder. Or P2 module: FOR HIM – aspiration chamber for primary cleaning with rotary feeder. For some models, optional P3 module: JAN – aspiration chamber for primary cleaning with rotary feeder and settling chamber. Standard cleaning aspiration module A2: JAB – aspiration chamber with adjustable channel. This module can be replaced with a module A3: UAE – aspiration chamber with adjustable channel and sedimentation chamber.Usage

Cleaning principle

Vibration is generated by two vibration motors. The cleaned product is sorted into three fractions: coarse impurities (not passing through the upper sieve), the main flow – the cleaned product and fine impurities (passing through the lower sieve). The cleaning efficiency is achieved up to 98%.Cleaning process

Modular cleaning JCM VibroMax

Examples of VibroMax cleaning configurations:

Intake air JAC – aspiration chamber for primary cleaning without rotary feeder JAM – aspiration chamber for primary cleaning with rotary feeder JAN – aspiration chamber for primary cleaning with rotary feeder and settling chamber

Purifier – cleaning the main fraction from impurities Calibrator – product sizing

Without exit aspiration JAA – Aspiration chamber with fixed channel JAB – Aspiration chamber with adjustable channel UAE – Aspiration chamber with adjustable channel and sedimentation chamberVibroMax modules

Aspiration options for feeding into the cleaning chamber

Sieve options

Exit after cleaning sieves

Exit aspiration options

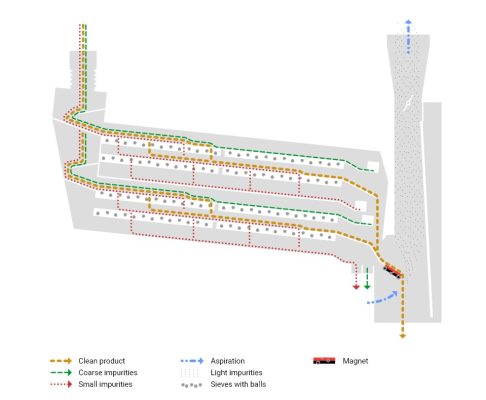

| JCM 08122 | JCM 10122 | JCM 10123 | JCM 10222 | JCM 10223 | JCM 15223 | JCM 10133 | JCM 15313 | |

|---|---|---|---|---|---|---|---|---|

| Capacity (pre-treatment), t/h | 25 | 60 | 60 | 100 | 100 | 200 | - | 300 |

| Capacity (industrial cleaning), t/h | 12 | 25 | 40 | 50 | 80 | 90 | 40 | - |

| Productivity (high-quality cleaning), t/h | 6 | 12 | 18 | 24 | 36 | 45 | 18 | 45 |

| Total sieve area, m2 | 1.9 | 3.4 | 5.1 | 6.8 | 10.2 | 12.6 | 7.65 | 9.45 |

| Length, mm | 2,280 | 2,810 | 3,680 | 3,133 | 3,920 | 4,004 | 3,865 | 4,405 |

| Width, mm | 1,275 | 1,645 | 1,645 | 1,645 | 1,645 | 2,479 | 1,645 | 2,485 |

| Height, mm | 1,645 | 1,905 | 1,900 | 2,236 | 2,330 | 3,589 | 2,083 | 4,127 |

| Weight, kg | 590 | 1,050 | 1,150 | 1,260 | 1,460 | 3,350 | 1,245 | 3,500 |

The Czech company JK Machinery, Ltd. is a well-known manufacturer both in the Czech Republic and on the international market. The company produces equipment for agriculture, the food industry, the chemical industry and the energy sector.

One of the areas of activity of this company is the production of vibrating grain cleaners for cleaning and sorting both large and small grains and seeds. The range of agricultural crop cleaning equipment produced will suit everything from small and medium-sized farms to large farms requiring high capacity.

An experienced team of employees will offer the best solutions for the implementation of client projects, taking into account even the most individual needs.