5000 and 8500 litre twin-chamber trailer-mounted hoppers

Falcon HW - high capacity twin chamber trailer mounted hoppers for fertiliser or seed

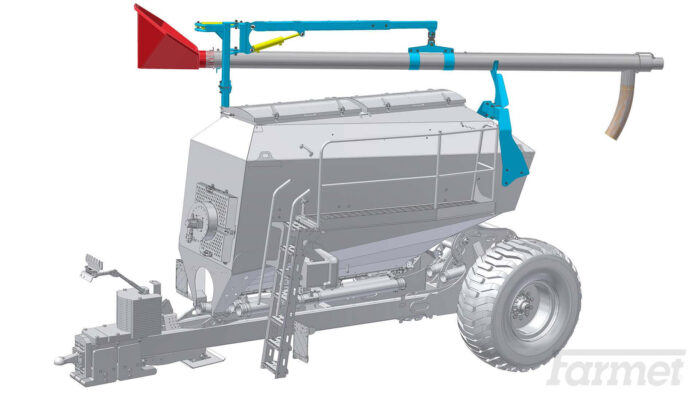

Falcon HW - is a two-chamber bunker with a capacity of up to 5 or 8,5 m³. It comes with high quality stainless steel screw dispensers, large diameter transport wheels (650/65-30.5) and solid construction, designed for fast movement of both in the fields, both by road.

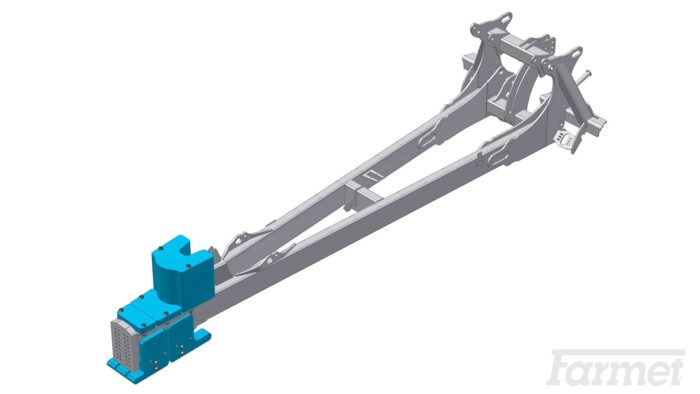

Falcon HW is intended primarily for for fertilisation in combination with tillage, but also perfectly suitable for for large-scale drilling, using aggregated drilling sections up to 9 m working width. The three-point suspension allows quick connection to a wide range of implements, including Digger deep cultivator.

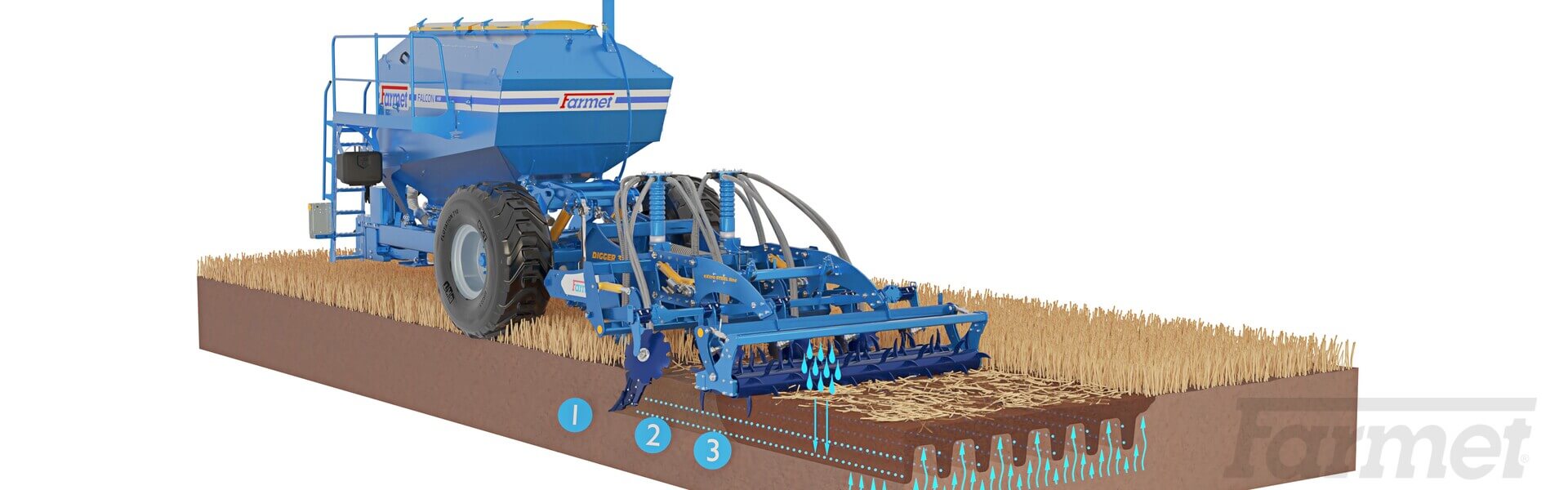

Falcon HW and Digger deep cultivator

1. Zone for deep loosening and placement of crop residues. Loosening depth 30-50 cm. The special shape of the loosening tines ensures excellent penetration even in heavily compacted soil with very low traction resistance. The tines are arranged in two rows. In particularly difficult conditions, it is possible to work with only one row of tines, thus reducing the traction resistance.

2. Fertiliser application zone. Granular fertiliser shall be placed in the swollen furrows at two depths.

3. Vag formation zone. The ironing discs also reinforce the effect of inserting plant debris.

4. Crushing and compaction zone. Optimum soil compaction ensures good water penetration and soil moisture retention.

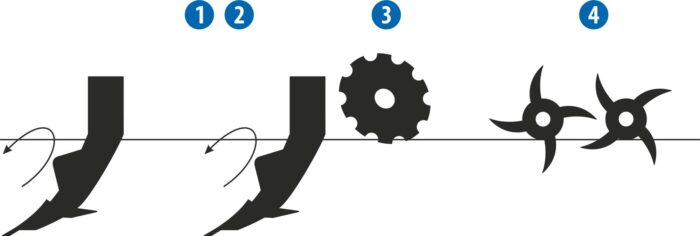

Falcon HW and drilling section

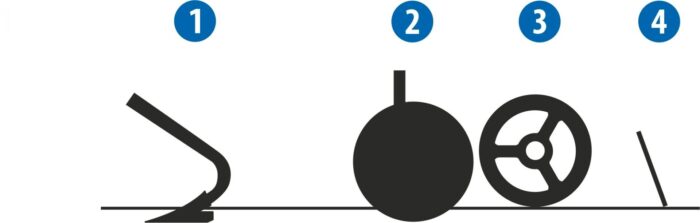

1. Loosening zone for tractor and tank trailer tracks. Perfect loosening of the crawler tracks eliminates uneven crop emergence after sowing.

2. Seedbed formation and seed placement area. The double disc coulters efficiently form a compacted seedbed (V-shaped groove) and precisely insert the seed to the required depth. Due to the high clamping force, up to 70 % of the total weight of the implement can be transferred to the sowing tines. The compressed bed and the V-shaped groove ensure excellent seed contact with the soil and soil moisture.

3. Lateral seed clamping zone. The copying wheel compresses the seed into a V-shaped groove, pressing it into the soil on the sides. The soil above the seed remains loose, which allows easy germination of the seedlings.

4. Seed sowing and soil levelling zone. The integrated harrow ensures perfect seed coverage and precise levelling of the soil surface.

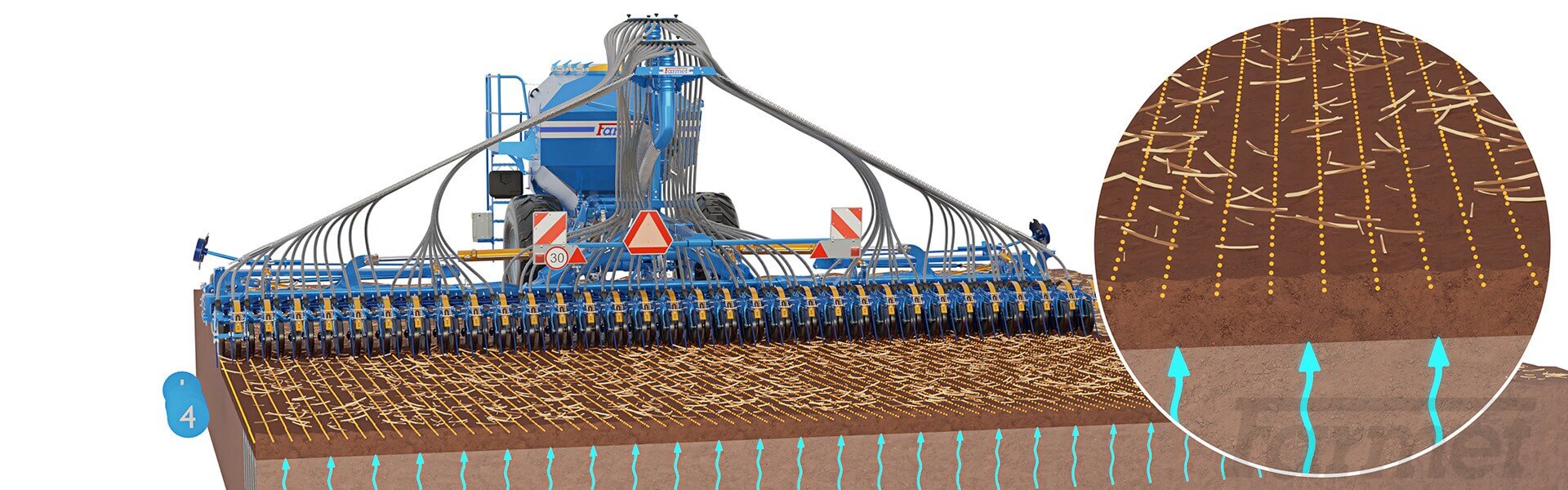

Falcon HW and Strip-Till

1. Plant residue crushing and spreading area. Plant residues are efficiently rolled and placed in the belts.

2. Shake zone. Loosening to a depth of 20-35 cm with a special tine geometry ensures wide strips of loosened soil.

3. Fertiliser application zone. Granular fertiliser shall be incorporated into the loosened soil strips at two depths.

4. Stripping zone. The large side discs effectively shape the shaky strips of soil and improve the quality of clod crushing.

5. Final crushing and compaction zone. Optimum soil compaction ensures good water infiltration and soil moisture gain.

High quality and efficient work

-

For basic tillage with fertiliser application or for sowing.

-

Possibility to dose 2 types of fertiliser or 2 types of seed separately.

-

Large, pressurised, twin-chamber hopper - 5,000 or 8,500 l.

-

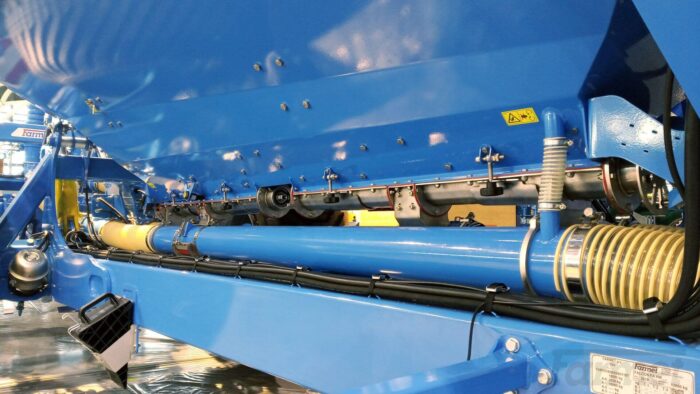

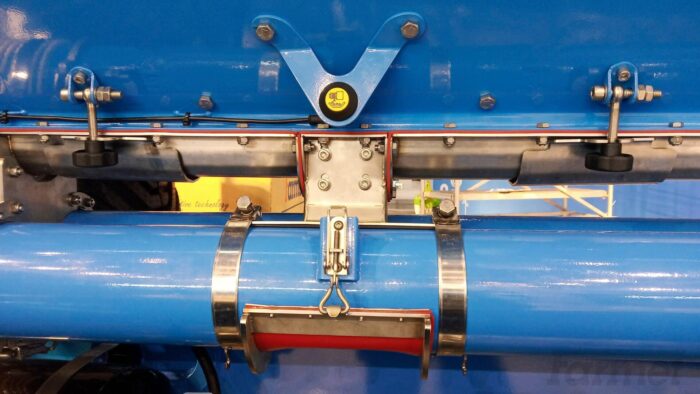

Reliable electronic system with stainless steel screw dispensers.

-

Sturdy construction and large transport wheels for stability and durability.

The reinforced high-capacity tank trailer with large-volume chamber and auger seed/fertiliser dispensers can be coupled with sowing sections or implements for tillage and fertiliser placement. It can be used for both basic tillage and subsequent sowing.

Falcon HW trailer-mounted hopper with adjustable fertiliser rate

iPad wireless connection (Wi-Fi)

3 hydraulic circuits for the attachment Electro-hydraulic flow distributor

Filling screw Work area surveillance camera

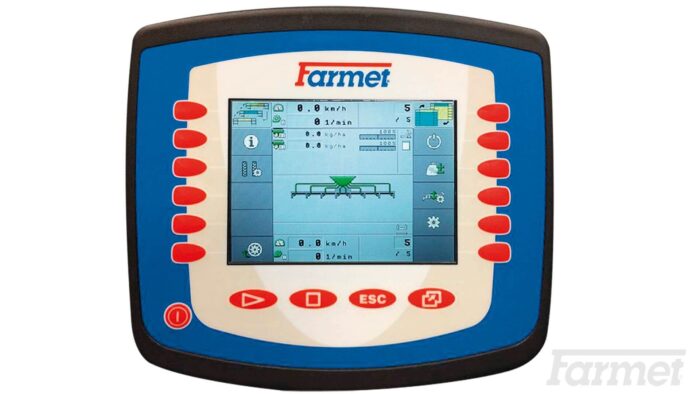

Control terminals

Seed counting and sowing control for each individual sowing disc.

iPad wireless connection (Wi-Fi) Topcon XD+ ME TOUCH800® BASIC terminal ME SMART570®

Screen dimensions 11" 12,1" 8" 5,7" 5,7"

Seed passage sensor control + + + + +

Seed hopper level indicator + + + + +

Fan speed monitoring + + + + +

Metering speed monitoring + + + + +

Engine speed monitoring + + + + +

Number of dosing motors 3 3 3 3

Track flap control + + + + +

Drill position display + + + + +

Work lighting control + + + + +

Seed box lighting control + + + + +

Marker control + + + + +

Prenatal marking management + + + + +

Seed replenishment during work + + + + +

Sowing small seeds + + + + +

Simultaneous windows 5 2 1 1

Video camera input + + + - -

GSM modem + for an additional fee - - -

Other optional equipment

1 hydraulic circuit as standard.

Divides one tractor hydraulic circuit into three separate circuits.

| Falcon 5000 HW | Falcon 8500 HW | |

|---|---|---|

| Transport width, mm | 2 990 | 2 990 |

| Transport height, mm | 2 600 | 3 900 |

| Total length, mm | 7 500 | 7 500 |

| Hopper capacity, l | 5 000 | 8 500 |

| Fertilizer rate, kg/ha | 50─500 | 50─500 |

| Working speed, km/h | 10─20 | 10─20 |

| Maximum possible slope, ° | 11 | 11 |

| Tire dimensions – for transportation | 650/65R-30.5 | 650/65R-30.5 |

| Towing | TPH categories 3 and 4; lower suspension K80; loop Ø 50, 70 mm | TPH categories 3 and 4; lower suspension K80; loop Ø 50, 70 mm |

| Weight, kg | 5 500 | 5 820 |

FARMETH – the largest manufacturer of agricultural machinery for tillage and sowing in the Czech Republic. The company, founded in 1992, is growing rapidly and devotes much attention and investment to the development of new technologies.

FARMETH agricultural equipment manufactured by this manufacturer must meet the strictest standards of work quality, reliability and durability. All equipment of this manufacturer 36 months warranty provided.

Products and technologies are developed in close collaboration with customers, research institutes and universities. FARMETH The products feature unique technological solutions, some of which are patented. The company seeks not only to improve product quality and create added value, but also to improve production technologies, productivity, and improve occupational safety and environmental protection.

FARMETH The brand is focused on high-quality products and high value. Major investments in modern production management ensure further quality improvement and more efficient production. The goal is to increase the added value of products and strengthen their competitiveness in all markets.