Tvirtos konstrukcijos, pažangus ir profesionalus ritinių presas–vyniotuvas

Naujasis Goweil G-1 F125 Kombi – idealiai suformuoti ritiniai ir maksimalus presavimo tankis

G-1 F125 Kombi sujungia presavimo ir vyniojimo darbus į vieną mašiną. Toks darbo principas leidžia nedelsiant pašalinti orą, todėl užtikrinama aukščiausia pašaro kokybė. Ši ritinių preso-vyniotuvo kombinacija leidžia dirbti ypač efektyviai: vienas operatorius, naudodamas tik vieną traktorių, gali tiek presuoti, tiek vynioti ritinius. G-1 F125 Kombi – tai profesionalus presavimo ir vyniojimo įrenginys, išsiskiriantis daugybe pažangių sprendimų ir funkcijų, užtikrinančių aukščiausią našumą.

GOWEIL G-1 F125 Kombi išskirtinumai

Laiko taupymas

Didelis šios preso–vyniotuvo kombinacijos našumas ir presavimo jėga leidžia sumažinti darbui laukuose reikalingą laiką. G-1 F125 Kombi gali dirbti iki 40 km/val. greičiu, todėl operatorius gali greitai įveikti ilgesnius atstumus tarp laukų.

Kaštų taupymas

Preso–vyniotuvo kombinacija leidžia sumažinti darbo jėgos ir technikos išlaidas iki minimumo.

Aukščiausia kokybė

Apvalūs ritiniai yra vyniojami itin švariai ir per ypač trumpą laiką. Greitas oro pašalinimas sukuria optimalias sąlygas pašaro fermentacijai, todėl užtikrinamas puikus išsilaikymas ir išskirtinė pašaro kokybė.

Profesionali technika

G-1 F125 Kombi sukurta profesionaliam naudojimui, todėl yra idealus pasirinkimas dideliems ūkiams ir paslaugas teikiantiems rangovams. Ji puikiai tinka šienainio, šieno ir šiaudų ritiniams presuoti bei vynioti.

High quality and efficient work

Aukščiausia pašaro kokybė

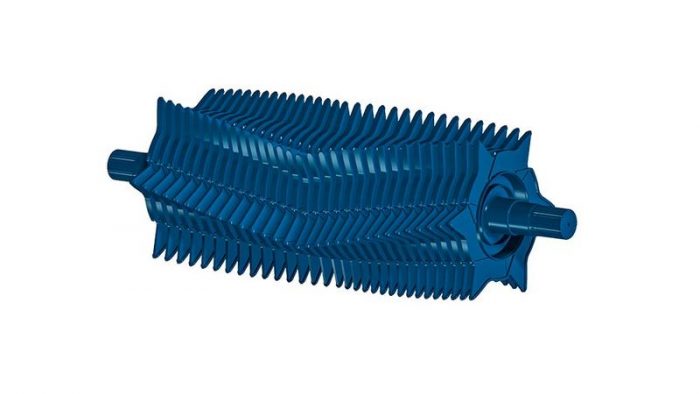

30 dvipusių peilių, kurių pjovimo ilgis siekia iki 35 mm, kartu su maksimaliu pašaro suspaudimu, leidžia suformuoti aukštos kokybės siloso ritinius.

Tobulas medžiagos srautas

Puikus prisitaikymas prie žemės paviršiaus ir didelis srauto pralaidumas. Automatinė srauto valdymo sistema užtikrina, kad rinktuvas ir rotorius neužsikimštų, todėl darbas vyksta tolygiai ir be pertraukų.

Plėvelės ir tinklo rišimas

Pageidaujant, apvalių ritinių presas gali būti komplektuojamas su plėvelės rišimo sistema, taip pat su dviguba rišimo sistema, skirta tiek tinklui, tiek plėvelei.

Dvigubas rišimas tinklui ir plėvelei

Dviguba tinklo ir plėvelės rišimo sistema leidžia sutrumpinti rišimo laiką perpus.

Kalnuotoms vietovėms

Varančioji ašis užtikrina maksimalų saugumą ir aukščiausio lygio komfortą bet kokioje šlaito padėtyje – tiek važiuojant į įkalnę, tiek nuokalnėje.

Momentinis oro pašalinimas

Ritinys vyniojamas iškart po išėjimo iš presavimo kameros, todėl oras pašalinamas nedelsiant.

Darbo procesas

Pašaro paėmimas

Pašaras surenkamas preso rinktuvu ir presavimo kameroje suformuojamas į ritinį.

Ritinio perdavimas

Tiesioginis ritinio perdavimas – greitai, švariai ir paprastai

- Vyniojimo stalas pasislenka po presavimo kamera. Kai ritinys visiškai suformuojamas, jis perduodamas iš presavimo kameros ant vyniojimo stalo, nepaliesdamas žemės paviršiaus.

Saugus ritinio nukreipimas net šlaituose

- Keturi ritinio nukreipimo volai užtikrina stabilų ritinio judėjimą. Tai leidžia patikimai ir saugiai perduoti ritinį, net dirbant nuolydžio ar kalnuotoje vietovėje. Perdavimo procesas trunka vos kelias sekundes – galinis dangtis užsidaro tuo metu, kai vyniojimo stalas juda į vyniojimo padėtį. Taip presavimo procesas gali tęstis be pertraukų.

Wrapping process

Dvigubas vyniojimo svirties mechanizmas ir du 750 mm pločio plėvelės tempimo įrenginiai užtikrina, kad ritinys būtų apvyniotas per ypač trumpą laiką. Vyniojimo procesas visada baigiamas greičiau nei presavimo procesas. Kadangi ritinys viso proceso metu yra tiksliai nukreipiamas ir stabiliai laikomas, jis puikiai apvyniojamas net dirbant šlaituose.

Ritinio padėjimas ant žemės

Kai ritinys visiškai apvyniojamas, plėvelė automatiškai nukerpama. Ritinio padėjimo metu vyniojimo stalas pasislenka atgal ir nusileidžia iki pat žemės, todėl ritinys švelniai padedamas, nepažeidžiant nei plėvelės, nei ritinio formos.

Tvirtai supresuoto ritinio kokybė prasideda nuo švaraus pašaro surinkimo rinktuvu. Švytuoklinė pakaba leidžia šešių eilučių švytuokliniam rinktuvui užtikrinti maksimalų padavimo našumą and puikų prisitaikymą prie žemės paviršiaus. Tokiu būdu įrenginys gali be vargo surinkti net didžiausias pradalges. Švytuoklinis rinktuvas Centrinėje padėtyje įrengta švytuoklinė pakaba suteikia 150 mm svyravimo amplitudę. Tai užtikrina puikų prisitaikymą prie žemės paviršiaus ir leidžia lengvai kompensuoti bet kokius nelygumus. Kadangi konstrukcijoje nėra kreipiančiojo disko, švytuoklinis rinktuvas pasižymi 2,20 m darbinio pločio (pagal DIN standartą) grėbimo juosta ir dideliu sraigtiniu padavimu šonuose, kuris užtikrina optimalų medžiagos tekėjimą į rotorių. Šešiomis eilėmis išdėstyti pirštai, kurių tarpai – 51 mm, leidžia rinktuvui užtikrinti puikų surinkimo našumą, net kai dirbama su itin plačiomis pradalėmis. Plastikiniai skyrikliai Dar viena išskirtinė savybė – plastikiniai skyrikliai. Jie yra ypač atsparūs apkrovoms ir nelinksta net susidūrę su pašaliniais objektais. Efektyviai atskirdami medžiagą nuo pirštų, skyrikliai taip pat pagerina pašaro tekėjimą per rinktuvą. Prispaudžiamasis volas su padavimo šukomis Prispaudžiamojo volo ir padavimo šukų sistema užtikrina tolygų pašaro tekėjimą, net kai dirbama su nelygiomis pradalgėmis, ir leidžia vienodai bei nuosekliai užpildyti presavimo kamerą. Lengvai riedantys atraminiai ratai Pneumatinėmis padangomis aprūpinti atraminiai ratai veikia idealiai derėdami su švytuokliniu rinktuvu ir pasižymi itin tolygiu riedėjimu. Rato aukštis reguliuojamas greitai ir paprastai – perforuotos kreipiančiosios leidžia tai atlikti be jokių įrankių. Pagal pageidavimą galima pasirinkti ir pasukamus atraminius ratus. Trumpai ir tiksliai supjaustytas pašaras yra aukštos kokybės ir didelės energinės vertės siloso gamybos pagrindas. GÖWEIL preso konstrukcijoje pašaras teka specialiu kanalu – per rotorių. Ši padavimo sistema užtikrina optimalų pašaro paėmimą ir padavimą bet kokiomis derliaus nuėmimo sąlygomis. Vienas rotorius visoms derliaus sąlygoms Padavimo sistemos centre įrengtas šešių žvaigždžių rotorius pasižymi itin didele įtraukimo galia. Dėl 570 mm skersmens ir suvirintų HARDOX pirštų eilučių, rotorius švariai pjauna pradalges ir patikimai tiekia pašarą į presavimo kamerą, nepriklausomai nuo to, ar pašaras yra stambus ir sausas, ar smulkesnis ir dar drėgnas. Prieš rotorių sumontuotas mechaniniu būdu varomas padavimo volas, kuris itin efektyviai suspaudžia medžiagą prieš patenkant jai į kamerą ir taip žymiai padidinda našumą. Naujai suprojektuotas starterio volas, įrengtas presavimo kameroje, užtikrina optimalų ritinio sukimąsi ir patikimą presavimo proceso pradžią. Tobulas medžiagos srautas G-1 F125 modelyje rotorius sukasi aukštyn nukreipta kryptimi. Toks judėjimas nukreipia pašarą iš rotoriaus per pjaustymo sistemą į presavimo kamerą, užtikrindamas tolygų ir nenutrūkstamą medžiagos tekėjimą. Atverčiamas dugnas ir pjaustymo sistema Kadangi pjaustymo sistema įrengta virš rotoriaus, peilius pakeisti labai paprasta – tai atliekama be jokių įrankių. Pjaustymo sistema turi 30 double-sided knives, leidžiančių pasiekti 35 mm pjaustymo ilgį. Mažas atstumas tarp rotoriaus pirštų ir peilių užtikrina, kad pašaras būtų supjaustytas itin tiksliai ir švariai. Keičiamoji peilių juosta leidžia operatoriui vežtis 30 atsarginių peilių arba keisti aktyvių peilių skaičių pagal poreikį. Hidraulinė apsaugos sistema saugo peilius nuo pašalinių objektų ir, suveikusi, automatiškai grąžina juos į darbinę padėtį. ASV sistema stebi visą medžiagos srautą ir visiškai automatiškai įsikiša, kai tik aptinkamas sutrikimas padavimo kanale. Tai užtikrina, kad rotoriaus ar rinktuvo užsikimšimai būtų pašalinami greitai ir be papildomų pastangų. Rotoriaus atkimšimas Kai padavimo kanalas tampa per siauras tiekiamam pašaro kiekiui, rotoriaus apsaugos nuo perkrovos sistema suveikia automatiškai. Viršutinis hidraulinis dugnas pakeliamas į viršų, o peiliai pasislenka atgal. Kai rotorius vėl paleidžiamas, perteklinis pašaras be kliūčių nukreipiamas į presavimo kamerą. Vėliau atverčiamas dugnas ir peiliai sugrįžta į pradinę padėtį, todėl pašaro paėmimas gali tęstis be jokių trukdžių. Rinktuvо atkimšimas Jei rinktuve susikaupia per daug pašaro, suveikia apsauga nuo perkrovos. Mašinos šerdyje yra presavimo kamera, kurios matmenys – 1,20 m x 1,25 m, o viduje įrengta 18 tvirtų formavimo volelių. Plieniniai voleliai, kurių sienelės storis 4 mm, yra sustiprinti iš vidaus, o jų briaunuotas paviršiaus profilis užtikrina maksimalų presavimo tankį ir patikimą ritinio sukimąsi. Presavimo kamera ir komponentai Du varantieji voleliai su 65 mm skersmens velenais ir papildomi 60 mm skersmens velenai sukasi ant dvieilių švytuoklinių ritininių guolių, kurie užtikrina išskirtinį stabilumą ir ypač ilgą tarnavimo laiką. Specialiai suprojektuotas labirintinis sandariklis neleidžia dulkėms ir nešvarumams patekti į guolius. Starterio ir valymo volai Tiesiai už rotoriaus sumontuotas starterio volas dėl savo specialaus profilio užtikrina optimalų ritinio sukimąsi ir patikimą presavimo pradžią, nepriklausomai nuo to, ar presuojamas šienainis, šienas ar šiaudai. Valymo volas surenka ir grąžina nukritusią medžiagą atgal į presavimo kamerą, taip apsaugodamas mašiną nuo nešvarumų kaupimosi. Galinė kamera (dangtis) Galinė preso kamera atsidaro ir užsidaro naudodama du hidraulinius cilindrus. Presas standartinėje komplektacijoje turi plėvelės ir tinklo rišimo sistemą. Papildomai gali būti sumontuota dviguba rišimo sistema, skirta tiek plėvelei, tiek tinklui. Plėvelės rišimo sistema Naudojant plačią plėvelę, gaunami esminiai pranašumai, kurie pagerina siloso kokybę: Operatorius gali naudoti standartines plačias plėveles arba tinklus iki 1,50 m pločio. Rišimo procesas gali būti pradedamas automatiškai arba rankiniu būdu. Hidrauliškai reguliuojamas stabdžio volas užtikrina, kad ritinys būtų tvirtai apvyniotas tiek tinklo, tiek plėvelės rišimo metu. Stabdžio slėgiai ir sluoksnių skaičius nustatomi tiesiogiai per valdymo pultą. Dvigubas rišimas perpus trumpesniu laiku Įdiegus pirmąją pasaulyje dvigubo rišimo sistemą, G-1 modelis žengia naują žingsnį apvalių ritinių presų technologijoje. Ši pasirenkama rišimo sistema leidžia vienu metu apvynioti ritinį dviem tinklais arba dviem plačiomis plėvelėmis. Rezultatas – rišimo laikas sutrumpėja perpus, taip pat dvigubai sumažėja laikas, reikalingas tinklo ar plėvelės keitimui. Toks sprendimas ženkliai sumažina operatoriaus darbo krūvį, o sutaupytas laikas ypač vertinamas intensyviausiu derliaus metu. Jei tą pačią dieną operatoriui reikia presuoti šienainio, šieno ar šiaudų ritinius, mašina leidžia dvigubą plėvelės rišimo sistemą naudoti kaip viengubą. Tokiu atveju vienas rišimo įrenginys įkeliamas tinklo ritiniu, o kitas – plėvelės ritiniu. Operatorius per valdymo terminalą paprastai nustato, kurį įrenginį naudoti tinklo rišimui, o kurį – plėvelės rišimui. Plėvelės ar tinklo keitimas atliekamas be jokių prastovų. Kaip papildoma įranga, varančioji ašis suteikia didelį pranašumą, ypač dirbant stačiuose šlaituose. Ji užtikrina galingą, bet dirvožemį tausojantį pastūmimą į įkalnę ir padeda stabdymo metu važiuojant nuokalnėn. Tai leidžia operatoriui visiškai susitelkti į darbą. Į jungiamąją svirtį (vilkties rėmą) integruota jutiklių sistema visiškai autonomiškai valdo važiavimo, laisvos eigos ir stabdymo režimus. Operatorius gali pasikliauti, kad sistema užtikrins maksimalią trauką kartu su dirvožemio apsauga, todėl jis gali visiškai susitelkti į darbo procesą. Aiškiai išdėstytame ekrane nuolat pateikiama visa svarbiausia informacija apie darbo parametrus. Pavara hidrauliškai varoma dviem radialiniais stūmokliniais / ratų stebulių varikliais. Pavaros kryptis (pirmyn arba atgal) keičiama automatiškai pagal signalą iš traktoriaus. Varančiosios jėgos pasiskirstymas pirmame ir antrame pavaros režimuose valdomas per terminalą. Kai mašina važiuoja į įkalnę – tiek pirmyn, tiek atbuline eiga – pavara automatiškai persijungia iš važiavimo režimo į hidrostatinio stabdymo režimą. Važiuojant keliu, radialiniai stūmokliniai varikliai automatiškai atjungiami mechaniškai ir sukasi laisvai, be mechaninio pasipriešinimo. GÖWEIL padalytos pavaros koncepcija užtikrina, kad Automatinis srauto valdymas (ASV) veiktų sklandžiai ir garantuotų itin didelį našumą. Per darbinio veleno (PTO) pavarą į pagrindinę pavarų dėžę perduodama galia tolygiai paskirstoma tarp rotoriaus, rinktuvo ir presavimo kameros pavaros grandinių, kurios kiekviena yra atskirai apsaugota dviem kumštelinėmis sankabomis. Šių sankabų veikimą stebi ISOBUS programinė valdymo sistema. Kai rotoriaus kumštelinė sankaba suveikia dėl per didelio pašaro kiekio padavimo kanale, hidraulinis atverčiamas dugnas automatiškai atsidaro. Kai presavimo kameros kumštelinė sankaba suveikia, galinis dangtis automatiškai prasiveria keliais centimetrais, leidžiant ritiniui pradėti formuotis ir būti surištam be trikdžių. Maksimalus našumas dėl ypač tvirtų grandinių Aukštos kokybės komponentai yra būtina sąlyga, kad pavaros sistema veiktų sklandžiai ir patikimai. Naujausios kartos mašinose naudojamos padidinto dydžio grandinės, skirtos pagrindinei pavarai, taip pat rinktuvo ir rotoriaus pavarai – tai dar labiau padidina visos sistemos našumą. Toks sprendimas ženkliai prailgina mašinos tarnavimo laiką ir sumažina eksploatacines išlaidas iki minimumo. Tvirtos ritininių guolių konstrukcijos Visi preso voleliai sumontuoti ant patvarių, dvieilių švytuoklinių ritininių guolių, kurių skersmuo – 60 mm. Be to, du varantieji voleliai aprūpinti dar didesniais– 65 mm guoliais, užtikrinančiais ypatingą tvirtumą ir ilgaamžiškumą. GÖWEIL šios kartos presus pateikia su ISOBUS sistema kaip standartine įranga. Valdymo sąsaja yra aiškiai išdėstyta ir lengvai valdoma, o spalvotas ekranas pateikia daugiau informacijos vienu metu. Be to, kamerų sistema suteikia operatoriui puikų matomumą darbo eigos ir mašinos veikimo metu. Papildomai galima pasirinkti ISOBUS terminalą G7 (7,0″) – su 10 valdymo mygtukų ir kodavimo ratuku. Šios mašinos, žinoma, yra suderinamos su visais kitais ISOBUS palaikančiais terminalais. Traktoriams, neturintiems ISOBUS sistemos, galima įsigyti papildomą ISOBUS maitinimo laidų komplektą. ISOBUS sistema visiškai automatiškai stebi ir valdo visą darbo procesą. G-1 F125 Kombi modelyje naudojamas mygtukinis valdymo blokas yra itin naudingas atliekant vyniotuvo priežiūros ar techninės apžiūros darbus, nes leidžia valdyti svarbiausias funkcijas tiesiogiai prie mašinos. Standartinėje komplektacijoje įrengta automatinė centrinio tepimo sistema užtikrina paprastą techninę priežiūrą ir itin ilgą mašinos tarnavimo laiką.

Tvirta ir patikima rėmo konstrukcija bei kokybiškas surinkimas užtikrina itin ilgą preso–vyniotuvo tarnavimo laiką. G-1 F125 Kombi pasižymi išskirtiniu manevringumu ir dirvožemį tausojančiu veikimu, kurį lemia kompaktiška konstrukcija ir nedidelis ašių atstumas. Be to, žemas svorio centras suteikia neprilygstamą valdomumą, net ir dirbant šlaituose. „Load Sensing“ sistema Standartinė hidraulinė „Load Sensing“ valdymo sistema automatiškai pritaiko alyvos srautą pagal faktinį poreikį. Tokia valdymo sistema leidžia vienu metu atlikti kelias funkcijas, kartu mažinant degalų sąnaudas. Rezultatas – didesnis ritinių kiekis per valandą. Be to, mašina gali būti naudojama ir su traktoriais, neturinčiais „Load Sensing“ siurblio. Chassis Dviejų ašių važiuoklė išsiskiria didesnias ratais – standartinėje komplektacijoje montuojamos Vredestein Flotation Trac 560/45-R22.5 padangos. Tolygi svorio paskirstymo sistema ir nedidelis atstumas tarp ašių užtikrina, kad presas–vyniotuvas būtų stabilus ir lengvai valdomas. Be to, apkrova dirvožemiui yra ženkliai sumažinta, todėl „Kombi“ gali sklandžiai važiuoti iki 40 km/val. greičiu, tiek minkštoje dirvoje, tiek kelyje. Nepaisant platesnių padangų, bendras mašinos plotis išlieka 3,00 m. Sudėtingesnėms darbo sąlygoms galima pasirinkti Nokian 710/35-R22.5 padangas, kurios padidina mašinos plotį iki 3,30 m. Be to, G-1 F125 Kombi gali būti komplektuojamas su dviejų linijų pneumatine stabdžių sistema arba hidrauline dviejų kontūrų stabdžių sistema. Mygtukinis valdymo blokas Valdymo blokas yra ypač naudingas atliekant mašinos techninę priežiūrą ar aptarnavimą. Jis leidžia operatoriui valdyti visas pagrindines funkcijas tiesiogiai prie vyniotuvo, todėl tokie darbai kaip plėvelės keitimas atliekami greitai ir paprastai. Dviguba vyniojimo svirtis su plėvelės tempimo įrenginiais Dviguba vyniojimo svirtis aprūpinta dviem 750 mm pločio plėvelės tempimo įrenginiais. Trys patentuoti plastikiniai voleliai užtikrina tolygų plėvelės tempimą, o jų konstrukcija yra atspari temperatūros pokyčiams. Dėl šios savybės sumažėja plėvelės sąnaudos, o ritiniai yra tvirtai ir hermetiškai apvyniojami. Tempimo įrenginiai yra reguliuojamo aukščio, todėl ritiniai visuomet apvyniojami tiksliai per jų centrą. Greito atleidimo sistema leidžia tuščius plėvelės ritinius pakeisti greitai ir be pastangų. Plėvelės stebėjimo sistema sustabdo vyniojimo procesą, jei plėvelė baigiasi arba nutrūksta. Kai vienas plėvelės ritinys išsenka, mašina automatiškai persijungia į vienos plėvelės režimą. Šiuo metu vyniojimo stalo padavimo greitis sumažinamas, kad būtų užtikrintas 50 % plėvelės persidengimas. Besisukanti vyniojimo svirtis su stacionariu vyniojimo stalu Ši sistema patikimai apsaugo ritinį nuo nukritimo, nes jo neveikia išcentrinės jėgos. Transporterinės juostos ir keturi besisukantys ritinio kreipiamieji volai užtikrina, kad ritinys nuolat judėtų į priekį, o tai leidžia tolygiai persidengti plėvelės sluoksniams. Kai ateina metas padėti ritinį ant žemės, mobilus vyniojimo stalas nuleidžiamas iki pat žemės, todėl ritinys švelniai padedamas, nepažeidžiant jo formos ir plėvelės. Uždara plėvelės saugykla Naujos konstrukcijos plėvelės saugykla pasižymi patobulintu dizainu ir funkcionalumu. Uždara, hidrauliškai atveriama plėvelės saugykla talpina 14 vyniojimo plėvelės ritinių and 2 plačios plėvelės arba tinklo ritinius, tuo pačiu apsaugodama juos nuo oro sąlygų ir pažeidimų. Pakreipimo mechanizmas leidžia operatoriui patogiai įkelti arba išimti plėvelę, išlaikant patogų darbo aukštį. Toks sprendimas leidžia apvynioti maždaug nuo 300 iki 400 ritinių, priklausomai nuo naudojamų plėvelės sluoksnių skaičiaus. Automatic film cutting and holding system Nerūdijančio plieno peiliai lygiai ir tiksliai nupjauna vyniojimo plėvelę. Tuo pat metu pjoviklio svirtis prilaiko plėvelę vietoje. Tik prasidėjus vyniojimo procesui standartinė padėtis leidžia lengvai išvynioti plėvelę.Collector

Padavimo sistema

Automatinis srauto valdymas (AVS)

Įprastai mechaniniu būdu varomas padavimo volas tuomet trumpam perjungiamas į hidraulinį valdymą, kad galėtų toliau tiekti medžiagą. Tuo pačiu metu atverčiamas dugnas pasislenka aukštyn, leisdamas pašarui tiesiogiai patekti į presavimo kamerą.Baling chamber

Priklausomai nuo pasirinktos programos nustatymo, šis procesas gali būti atliekamas automatiškai arba rankiniu būdu.Plėvelės ir tinklo rišimas

Varančioji ašis

Kad ratai neužsiblokuotų, abiejų varančiųjų ratų greitis nuolat stebimas ir automatiškai reguliuojamas, todėl važiuojant į įkalnę ratai visada išlieka judantys (ABS funkcija).Gear

Kai rotorius vėl paleidžiamas, perteklinis pašaras be kliūčių nukreipiamas į presavimo kamerą, o dugnas automatiškai užsidaro, leidžiant presavimo procesui tęstis be pertraukų.ISOBUS control

Aiškiai struktūruotas ekranas nuolat pateikia operatoriui visą informaciją apie atliekamus darbo etapus. Taip pat galima rankiniu būdu per terminalą greitai ir patogiai valdyti pagrindinius darbo žingsnius.Maintenance

Wrapping process

Hidraulinė sistema

- „Load Sensing“ (gali būti naudojama ir su traktoriais be „Load Sensing“ siurblio)

Collector

- Besisukantis švytuoklinis rinktuvas be kreipiančiojo disko

- Darbinis (grėbimo) plotis pagal DIN standartą: 2,20 m

- Pirštų eilučių skaičius: 6

- Pirštų tarpai: 51 mm

- Plastikiniai skyrikliai

- Prispaudžiamasis volas su padavimo šukomis

- Atraminiai ratai su pneumatinėmis padangomis

- Pasukami atraminiai ratai (pasirenkama įranga)

Padavimo sistema

- Šešių žvaigždžių rotorius

- Hidraulinis atverčiamas dugnas

- Pjaustymo sistema su 30 dvipusių reversinių peilių

- Pjaustymo ilgis: 35 mm

- Hidraulinė apsaugos juosta nuo pašalinių objektų

Baling chamber

- 18 plieninių volelių (4 mm), sustiprintų iš vidaus (įskaitant valymo ir starterio volus)

- Dvieiliai švytuokliniai ritininiai guoliai

- Siloso priedų dozavimo sistema (pasirenkama įranga)

Rišimo sistema

- Plėvelės ir tinklo rišimas

- Hidrauliškai reguliuojamas stabdžio volas

- Automatinė stebėjimo sistema

- Dvigubo rišimo įrenginys (pasirenkama įranga)

Jungiamoji svirtis

- Fiksuota jungiamoji svirtis

- Hidrauliškai valdoma lanksti jungiamoji svirtis (pasirenkama įranga)

- Hidrauliškai valdoma lanksti jungiamoji svirtis su amortizacija (pasirenkama įranga)

Važiuoklė ir padangos

- Tandem chassis

- Padangos: 560/45-R22.5 Flotation Trac

- Stabdžių sistema: dviejų linijų pneumatinių stabdžių sistema

- Padangos 650/40-R22.5 Vredestein Flotation Trac: bendras plotis – 3 150 mm (pasirenkama įranga)

- Padangos 710/35-R22.5 Nokian Country King Flotation Trac: bendras plotis – 3 290 mm (pasirenkama įranga)

- Pilna varančioji ašis (pasirenkama įranga)

- Hidraulinė dviejų linijų stabdžių sistema (pasirenkama įranga)

Gear

- Darbinio veleno (PTO) greitis: 1 000 aps./min

- ASV (Automatinis srauto valdymas): padalytos pavaros koncepcija

- Apsauga nuo perkrovos: 2 kumštelinės sankabos

- Grandinės:

- Pagrindinė pavara – presavimo kamera: 24 BH

- Antrinė presavimo kameros pavara: 100 HSP

- Rotorius: 80 HSP Triplex

- Rinktuvas: 80 HSP

Maintenance

- Pilnai automatinė centrinio tepimo sistema – skirta tepalui ir alyvai

Valdymo sistema

- Pilnai automatinis ISOBUS programinis valdymas (be terminalo)

- Kamerų sistema (2 kameros – rišimo ir ritinio padėjimo stebėjimui, įskaitant spalvotą monitorių)

- ISOBUS terminalas S (4,3″) – su 8 valdymo mygtukais ir kodavimo ratuku (pasirenkama įranga)

- ISOBUS terminalas S (7,0″) – su 12 valdymo mygtukų ir kodavimo ratuku (pasirenkama įranga)

- ISOBUS maitinimo jungtis traktoriui (pasirenkama įranga)

- Valymo įranga su suslėgto oro žarna ir oro pūstuvu (galima tik su dviejų linijų pneumatine stabdžių sistema) (pasirenkama įranga)

- 4 jungiamosios vilkties kilpų pasirinkimai (pasirenkama įranga)

- Įspėjamasis švyturėlis (pasirenkama įranga)

Winder

- Dviguba vyniojimo svirtis

- Hidrauliškai valdoma mobili vyniojimo platforma

- 4 ritinio transporterio juostos su kreipiančiuoju mechanizmu

- 4 ritinio kreipiamieji volai

- Plėvelės tempimo įrenginys, skirtas 750 mm pločio plėvelei

- Plėvelės pjovimo mechanizmas – tikslaus pjovimo sistema

- Vienos plėvelės darbo režimas

- Uždara, hidrauliškai nuleidžiama plėvelės saugykla, talpinanti 14 vyniojimo plėvelės ritinių ir 2 plačios plėvelės arba tinklo ritinius

- LED darbo žibintai

- Papildomas volas vyniojimo stalui

- Kombinuotas plėvelės tempimo įrenginys (tinka 500 ir 750 mm pločio plėvelei) (pasirenkama įranga)

- Papildomas ritinio pasukimo įtaisas (pasirenkama įranga)

- Apsauginis smūgių kilimėlis (pasirenkama įranga)

- Ritinių vertikalaus padėjimo įtaisas (ritinio vertikliuvas) (pasirenkama įranga)

- Ritinio stabdiklis vertikliuvei (naudojamas tik kartu su ritinio vertikliu ir ISOBUS sistema) (pasirenkama įranga)

- Ritinio gaudyklė (naudojama tik kartu su ISOBUS sistema) (pasirenkama įranga)

| G1 F125 COMBI | |

|---|---|

| Bendras viengubo ir dvigubo rišimo aukštis be / su įspėjamuoju švyturėliu, mm | 2 820 / 2 980 |

| Total length, mm | 7 420 |

| Overall width (with standard 560/45-R22.5 tires), mm | 3 000 |

| Bendras plotis (su pasirenkamomis 650/40-R22,5, padangomis), mm | 3 300 |

| Overall width (with optional 710/35-R22.5 tires), mm | 3 300 |

| Total weight, kg | 8 980 |

| Power shaft speed, rpm | 1 000 |

| Roll diameter, m | 1,25 |

| Alyvos poreikis esant 200 bar slėgiui, nuo l/min | 80 |

| Optimalus alyvos poreikis esant 200 bar slėgiui, nuo l/min | 105 |

| Minimum power requirement, HP | 120 |

Over the past few decades, since 1988, GOWEIL has established itself in the market as a specialist in the production of hay bale wrappers. Since the company GOWEIL Maschinenbau GmbH exports the majority of its production – the 86% – and the machines are known and widely used all over the world. All machines and equipment are designed, developed and manufactured exclusively at the company's headquarters in Kirchschlag (Upper Austria).

All GOWEIL The products reflect the latest technologies and are designed to meet the individual needs of farms.