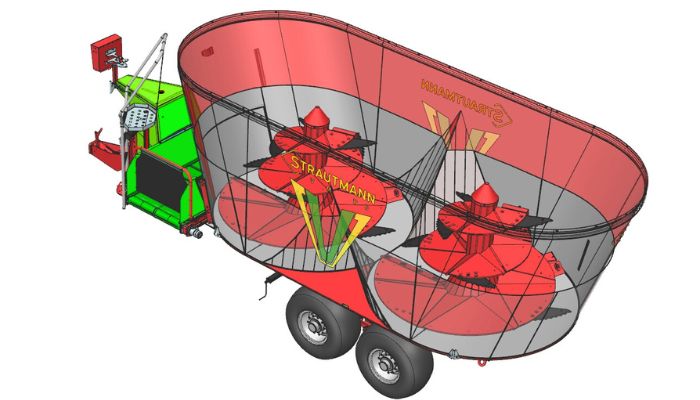

Self-propelled 14–20 m³ capacity feed mixer-distributors with a quick cutting system

Verti-Mix SF – the optimal and comprehensive solution for professional feeding

Loading, mixing and unloading are all done with one machine. Since an additional loading unit is no longer required and all components work together extremely efficiently, the work is done comfortably and with fuel savings. The integrated remote maintenance modem turns the self-propelled Strautmann model smart and reliable a comprehensive tool for feeding work.

The Verti Mix SF is unique due to its efficient tiller and new powerful 6-cylinder engine, compliant with emission level 5.. Self-propelled feed mixers significantly simplify the labor-intensive process of feeding dairy cows and help save time, money and labor. A uniformly mixed feed mixture prevents cows from selecting only certain feed components, so higher milk yield is achieved, all animals are fed exactly according to their physiological needs and are less likely to get sick.

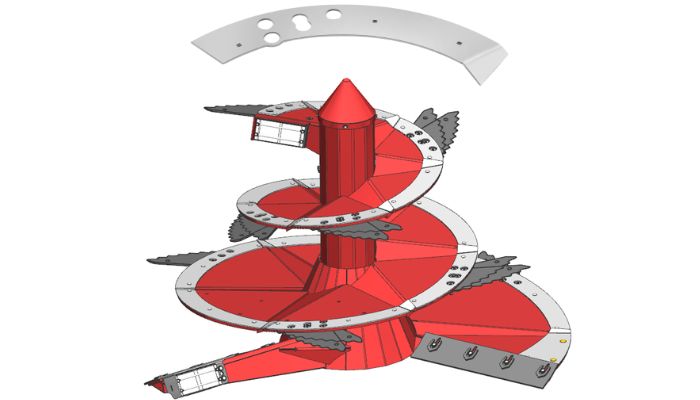

IMS mixing screw – versatility and robustness for any job. Strautmann Verti-Mix feed mixing trailers significantly contributes to the productivity of modern dairy farms increaseThe perfect geometry of the container and IMS mixing auger is complemented by a newly developed stair-step auger design with 60-degree elements. Excellent mixing quality and proven easy towing ensure maximum economy in all operating conditions.

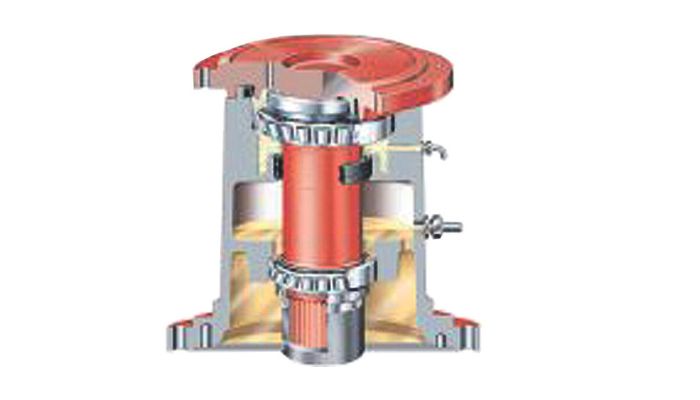

Adjustable front auger tip/scraper Thanks to the adjustable scraper belts, even the smallest ingredients are reliably collected from the ground and mixed evenly. Solid foundation The IMS mixing screw is based on a very robust and durable gearbox. Stability and long maintenance intervals are ensured by large tapered roller bearings, double sealing and a capacious oil chamber. Efficient mixing Ideally matched mixing screw geometry and distance to the tank wall – for fast and uniform mixing.

INNODUR elements made of highly resistant metal Optional INNODUR wear elements significantly extend the service life of the IMS mixing auger.

Stainless steel finish In diets with a high corn content (>75% of dry matter in the total diet), the amount of aggressive lactic acid increases significantly. This acid corrodes the tank material and promotes the formation of rust layers. The stainless steel finish effectively protects the tank from this damage.

Special equipment options help you to tailor your IMS mixing auger even better to your individual needs:

With the rear part lateral projection control

Without rear part lateral projection control

ICS system assembly mode

ICS system travel mode

ICS system unloading mode

Scale system is an integral part of the feed mixer. Precise determination of the quantity of individual ingredients allows you to maximize and economically utilize your feed mixer. In addition to the standard programmable weighing system integrated with ICS control, other options are available to meet the specific needs of your farm.

CowConnect Box system with weighing bars and holder

PTM advanced Super USB pprogrammable weighing system Comprehensive feeding control management, including time recording, is essential for optimizing costs on dairy farms.

PTM AV 40 screen

PTM AV 75 radio remote control system:

Universal helper – IMS (Intensive Mix System) mixing auger

Thanks to the patented blade adjustment system, the IMS mixing auger can be precisely adapted to the specific working conditions. The robust and low-maintenance angular gear ensures a long service life even under difficult working conditions.

Longer service life and lower costs

Equipment tailored to your individual needs

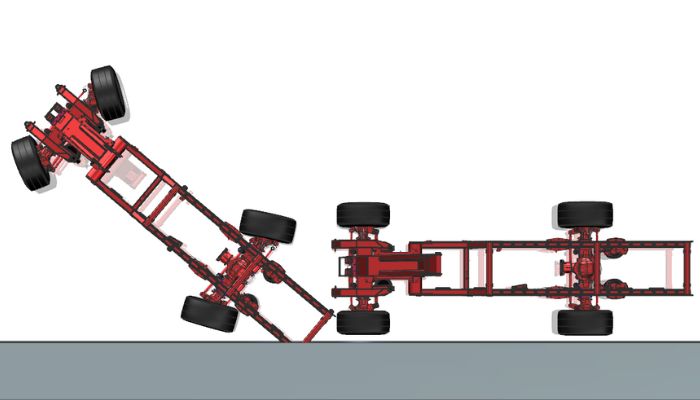

Increased safety – rear overhang control

ICS control system that controls everything

Precision Feeding – Other Scale Options

Milling cutter

Conical funnel behind the cutter

Elevator

Feed collection and transportation

Mineral feed feed valve

Front cross conveyor

Laterally pushed cross conveyor

Rear cross conveyor

Front cross conveyor with extension

Rear discharge on the right or left side

Rear central discharge with protective cover

Side discharge

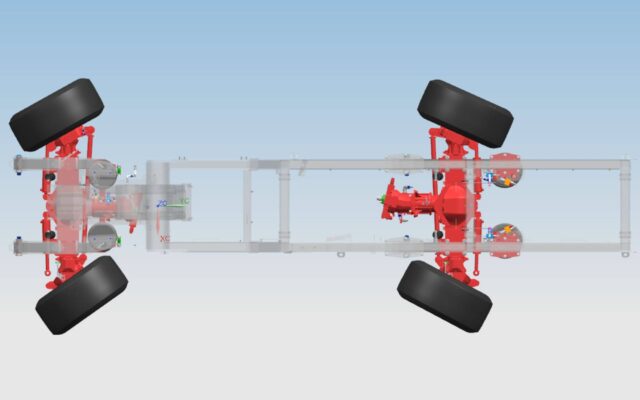

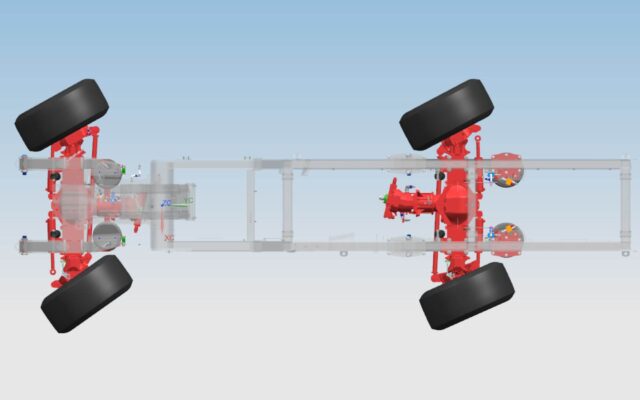

Drive system

Spring suspension

Air suspension

Intelligent steering system

Four-wheel drive system

Diagonal steering

Lighting

Mineral feed hopper

Counter knives

6-cylinder engine

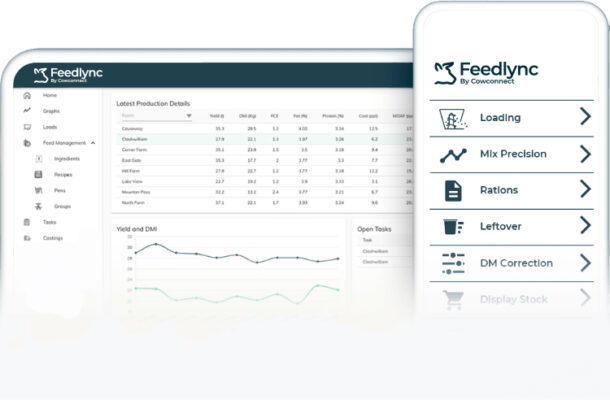

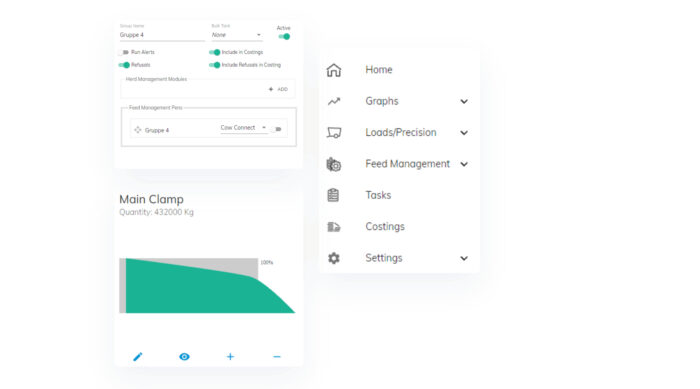

A unique cloud-based solution that will help you accurately track, manage, and otherwise streamline feeding operations.

Feedlync seamlessly integrates with your farm's external systems and automatically imports milk yields and cow numbers. Stay connected to your farms and feeding process, get automated, reliable data instantly, work proactively with multiple farms by viewing their data. Change rations, add or remove ingredients, manage pens and groups remotely. Feedlync integrates with several external systems to provide accurate and detailed costing. Feedlync has a lot of features that help you save time and work more efficiently

Active monitoring Track feed consumption, price per liter and more. Real-time data exchange Get data to your app in real time from anywhere in the world. Weather corrections Adjust the feeding plan to ensure that weather conditions do not affect milk yield. Low stock alerts You will be notified when the stock of silage or other feed reaches a defined minimum quantity. Farm data interfaces Feedlync integrates with other systems, saving you time and money. Saved reports Change saved recipe data to avoid feed waste and increase profits. Cloud backup Copies of your data are automatically saved, without the risk of losing anything. Charts and analysis The app helps you clearly see and understand the collected data and costs. Animal health Accurate feeding data provides the best understanding of your animals' health.Feedlync intelligent feeding management system

Router

Feedlync integrates with your existing systems

Data at your fingertips

Direct monitoring of farm expenses

But that's not all.

| Verti-Mix 140 Double SF | Verti-Mix 170 Double SF | Verti-Mix 200 Double SF | |

|---|---|---|---|

| Useful capacity, m3 | 14 | 17 | 20 |

| Useful capacity with extension, m3 | 16 | 19 | 22 |

| Width with cross conveyor, mm | 2 360 | 2 360 | 2 360 |

| Outer wheel width, front, mm | 2 320 | 2 320 | 2 320 |

| Length with cross conveyor at the front, mm | 8 970 | 9 030 | 9 340 |

| Length with cross conveyor at the end, mm | 9 180 | 9 180 | 9 460 |

| Elevator width, m | 0.58 | 0.58 | 0.58 |

| Cutter diameter, m | 0,61 | 0,61 | 0,61 |

| Working width, m | 2,00 | 2,00 | 2,00 |

| Reachable height, m | 5,00 | 5,10 | 5,10 |

| Weight of the base model from, kg | 12 800 | 13 100 | 13 400 |

| Wheelbase, mm | 3 760 | 3 760 | 3 940 |

| Height with 435/50 R 19.5 wheels, mm | 2 810 | 2 930 | - |

| Height with 455/45 R22.5 wheels, mm | 2 810 | 2 960 | 3 060 |

A family-run company based in northern GermanyB. Strautmann & Söhne GmbH u. co. KG"has been around for over 85 years.

STRAUTHMANN The factory has developed a wide range of products, especially well suited for livestock farms. The company can offer silage handling equipment for various purposes: silage buckets, silage cutters and silage block cutters for easy silage removal.

STRAUTHMANN Silage block and feed transport trailers have been ensuring fast and easy feed supply for several decades. We also manufacture trailed and self-propelled feed mixers - perfect for preparing physiologically ideal animal feed.

For optimal feed quality, STRAUTHMANN presents grass silage handling equipment. In order to maintain the best quality of feed, the grass loaded into the self-loading trailer is gently but optimally chopped. Customers can purchase tri-axle trailers and dump trucks as well as trailers for convenient feed transportation. Also, manure and universal shakers are available in various sizes. Thus, by creating a high-quality and diverse product offering, STRAUTHMANN the company becomes a competent partner for the farmer.