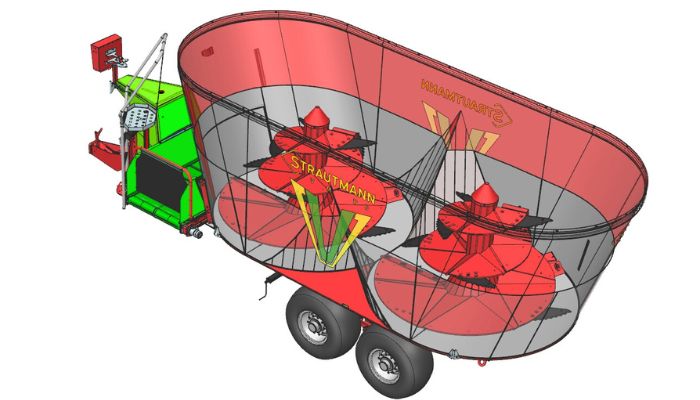

Self-propelled 12 – 14 m³ capacity feed mixer-distributors with a fast cutting system

Sherpa – Your way into the world of self-propelled feed mixers

New generation self-propelled Strautmann feed mixeri significantly simplifies the labor-intensive process of feeding dairy cattle - saving time, money and labor.

Mixing different ingredients until smooth prevents cows from choosing their feed. This affects higher milk yield by using higher quality and more nutritionally valuable feed.

All animals are fed optimally according to their physiological needs, so they are less likely to get sick. The result is healthy cows and high economic efficiency..

High quality and efficient work

- 12 – 14 m³ capacity

- One mixing screw

- Extremely easy to maneuver

- Low overall height

- Easy to operate

- Fast cut system

- Silage loading, mixing and feed distribution processes combined in one machine

- A great choice for starting to work with self-propelled feed mixers-distributors

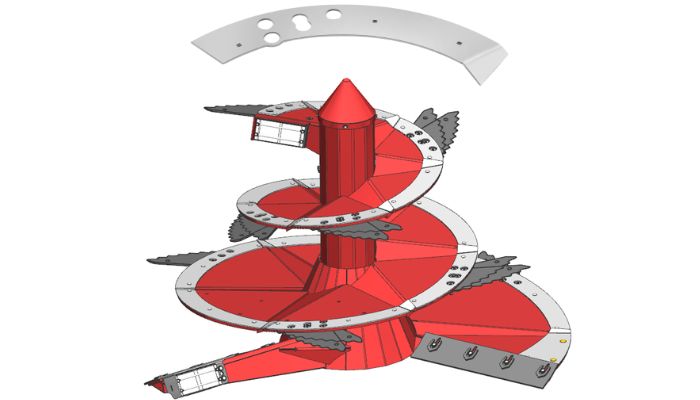

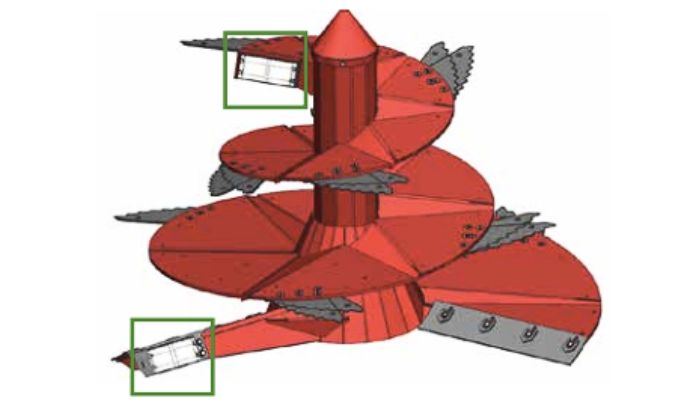

IMS mixing screw – versatility and robustness for any job. Strautmann Verti-Mix feed mixing trailers significantly contributes to the productivity of modern dairy farms increaseThe perfect geometry of the container and IMS mixing auger is complemented by a newly developed stair-step auger design with 60-degree elements. Excellent mixing quality and proven easy towing ensure maximum economy in all operating conditions.

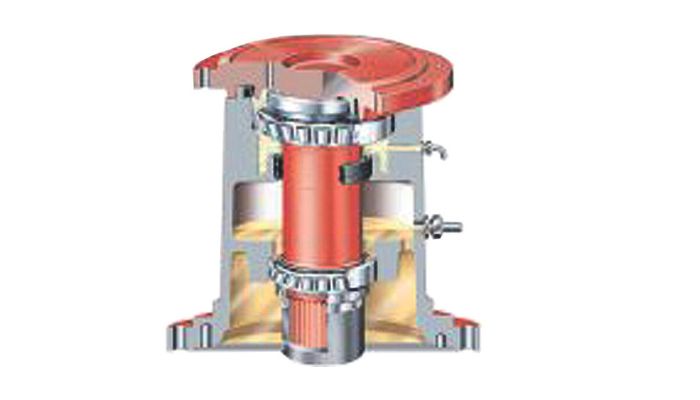

Adjustable front auger tip/scraper Thanks to the adjustable scraper belts, even the smallest ingredients are reliably collected from the ground and mixed evenly. Solid foundation The IMS mixing screw is based on a very robust and durable gearbox. Stability and long maintenance intervals are ensured by large tapered roller bearings, double sealing and a capacious oil chamber. Efficient mixing Ideally matched mixing screw geometry and distance to the tank wall – for fast and uniform mixing.

INNODUR elements made of highly resistant metal Optional INNODUR wear elements significantly extend the service life of the IMS mixing auger.

Stainless steel finish In diets with a high corn content (>75% of dry matter in the total diet), the amount of aggressive lactic acid increases significantly. This acid corrodes the tank material and promotes the formation of rust layers. The stainless steel finish effectively protects the tank from this damage.

Special equipment options help you to tailor your IMS mixing auger even better to your individual needs:

Magnetic system

After 14 days of using the magnetic system

Knife for unrolling round rolls

PTM Advanced Super USB Programmable Scale System Comprehensive feeding control, including time recording, is essential for optimizing costs on dairy farms.

CowConnect Box system with weighing bars and holder Alternative: Use your smartphone with WLAN as a terminal!

Universal helper – IMS (Intensive Mix System) mixing auger

Thanks to the patented blade adjustment system, the IMS mixing auger can be precisely adapted to the specific working conditions. The robust and low-maintenance angular gear ensures a long service life even under difficult working conditions.

Longer service life and lower costs

Equipment tailored to your individual needs

Wireless data transmission – WLAN-compatible weighing system

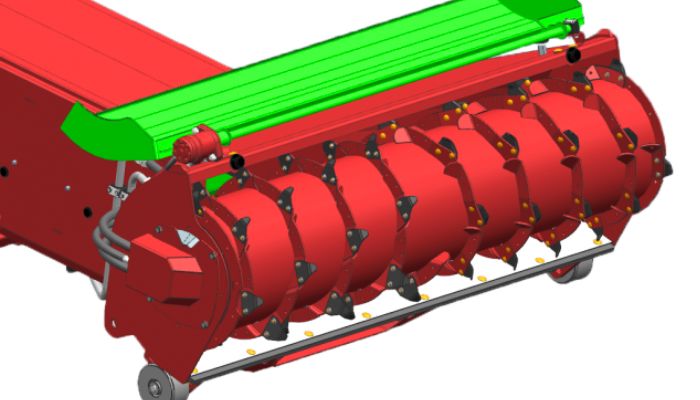

Milling cutter

Conical funnel behind the cutter

Elevator

Feed collection and transportation

Side discharge of feed

Optional conveyor

Protective cover between the mixing screw and the coaxial reducer

Axle and suspension

Feed hoppers and mixer drive

Counter knives

Lighting and cameras

Driver's cab

Management

PTM AV 75 Radio remote control

PTM HL 50 – programmable weighing system – the entry-level model of Strautmann weighing scales

4-cylinder turbodiesel engine

| Sherpa 120 | Sherpa 140 | |

|---|---|---|

| Useful capacity, m³ | 12 | 14 |

| Total length during transport, mm | 8,250 | 8,250 |

| Total width with one-sided unloading, mm | 2,520 | 2,520 |

| Total width with double-sided unloading, mm | 2,620 | 2,620 |

| Overall height (mechanical chassis suspension), mm | 2,540 | 2,790 |

| Wheelbase, mm | 3,860 | 3,860 |

| External width between wheels at the front, mm | 2,310 | 2,310 |

| External width between wheels at the rear, mm | 1,940 | 1,940 |

| Turning radius (external front), mm | 5,260 | 5,260 |

| Turning radius (external rear), mm | 5,730 | 5,730 |

| Turning radius (internal), mm | 1,430 | 1,430 |

| Working width of the cutter, mm | 2,000 | 2,000 |

| Reachable height, mm | 4 500 | 4 500 |

| Drum diameter, mm | 610 | 610 |

| Elevator width, mm | 580 | 580 |

| Net weight, kg | 10,200 | 10,300 |

A family-run company based in northern GermanyB. Strautmann & Söhne GmbH u. co. KG"has been around for over 85 years.

STRAUTHMANN The factory has developed a wide range of products, especially well suited for livestock farms. The company can offer silage handling equipment for various purposes: silage buckets, silage cutters and silage block cutters for easy silage removal.

STRAUTHMANN Silage block and feed transport trailers have been ensuring fast and easy feed supply for several decades. We also manufacture trailed and self-propelled feed mixers - perfect for preparing physiologically ideal animal feed.

For optimal feed quality, STRAUTHMANN presents grass silage handling equipment. In order to maintain the best quality of feed, the grass loaded into the self-loading trailer is gently but optimally chopped. Customers can purchase tri-axle trailers and dump trucks as well as trailers for convenient feed transportation. Also, manure and universal shakers are available in various sizes. Thus, by creating a high-quality and diverse product offering, STRAUTHMANN the company becomes a competent partner for the farmer.