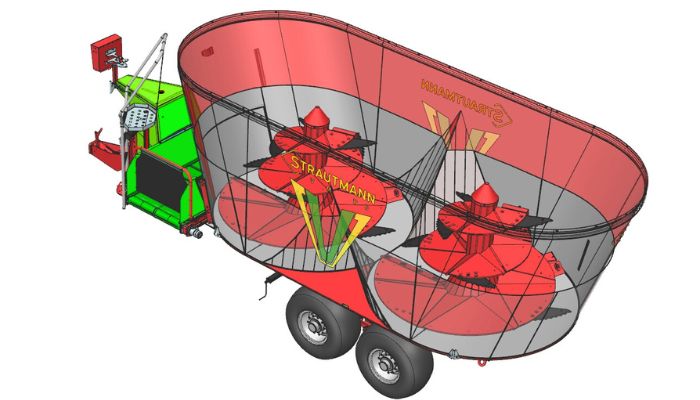

Self-propelled 17 – 22 m³ capacity feed mixer-distributors with a quick cutting system

Self-propelled feed mixer trailer Primus 600

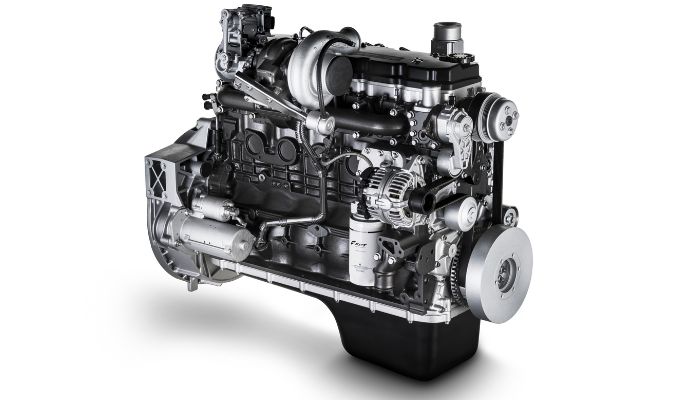

A complete solution with a powerful 6-cylinder engine, efficient milling unit and the new Smart Feed cab. Smart and reliable loading, mixing and unloading with one implement.

Since a separate loading device is no longer needed and all components work efficiently with each other, work is carried out comfortably and with fuel savings.

Integrated remote monitoring modem turns self-driving Strautmann model with smart, reliable and versatile technology.

Main advantages:

- 17–22 m³ mixing volume

- High-performance milling machine

- 2 IMS mixing screws

- 2 m milling width

- Various unloading options

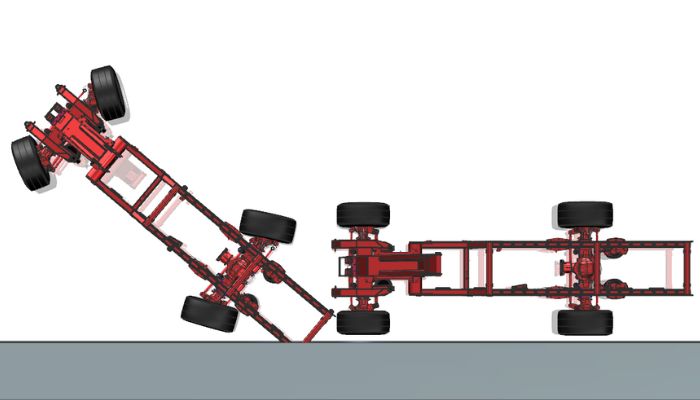

- Different chassis configurations

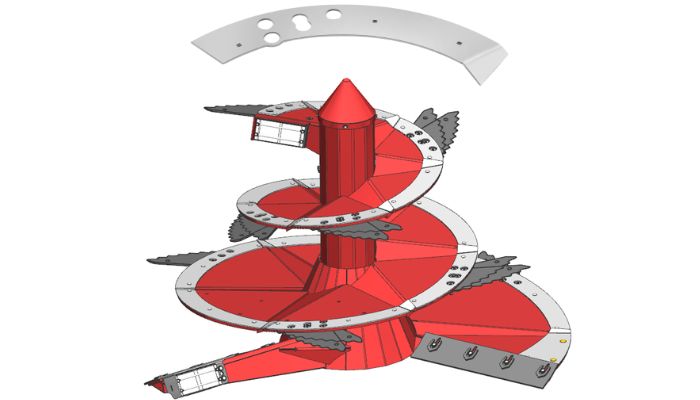

IMS mixing screw – versatility and robustness for any job. Strautmann Verti-Mix feed mixing trailers significantly contributes to the productivity of modern dairy farms increaseThe perfect geometry of the container and IMS mixing auger is complemented by a newly developed stair-step auger design with 60-degree elements. Excellent mixing quality and proven easy towing ensure maximum economy in all operating conditions.

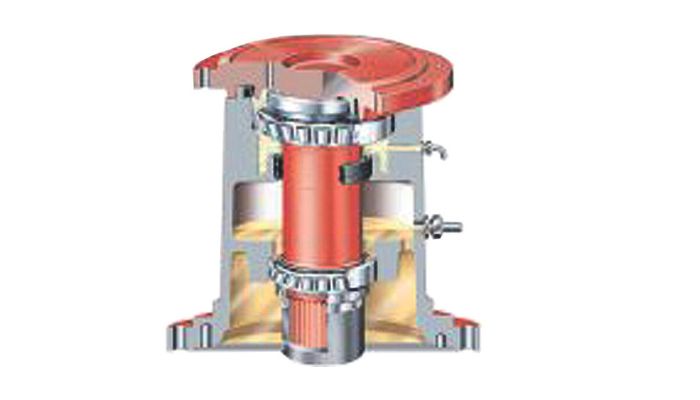

Adjustable front auger tip/scraper Thanks to the adjustable scraper belts, even the smallest ingredients are reliably collected from the ground and mixed evenly. Solid foundation The IMS mixing screw is based on a very robust and durable gearbox. Stability and long maintenance intervals are ensured by large tapered roller bearings, double sealing and a capacious oil chamber. Efficient mixing Ideally matched mixing screw geometry and distance to the tank wall – for fast and uniform mixing.

INNODUR elements made of highly resistant metal Optional INNODUR wear elements significantly extend the service life of the IMS mixing auger.

Stainless steel finish In diets with a high corn content (>75% of dry matter in the total diet), the amount of aggressive lactic acid increases significantly. This acid corrodes the tank material and promotes the formation of rust layers. The stainless steel finish effectively protects the tank from this damage.

Special equipment options help you to tailor your IMS mixing auger even better to your individual needs:

With the rear part lateral projection control

Without rear part lateral projection control

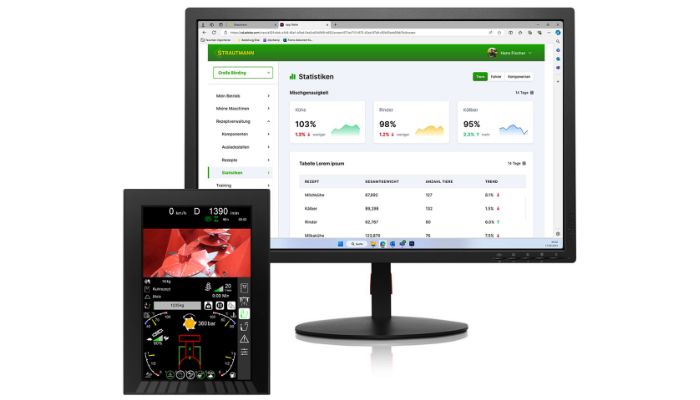

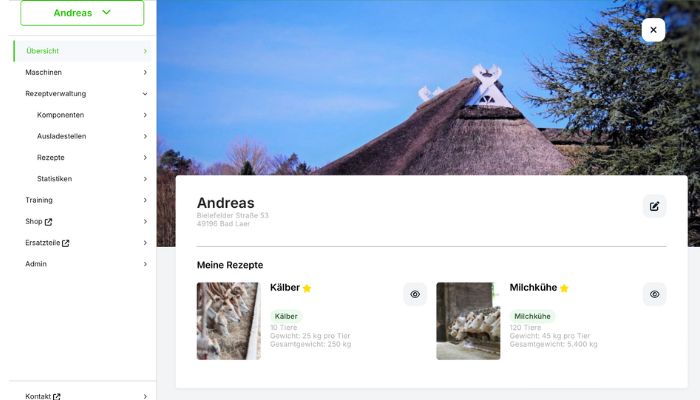

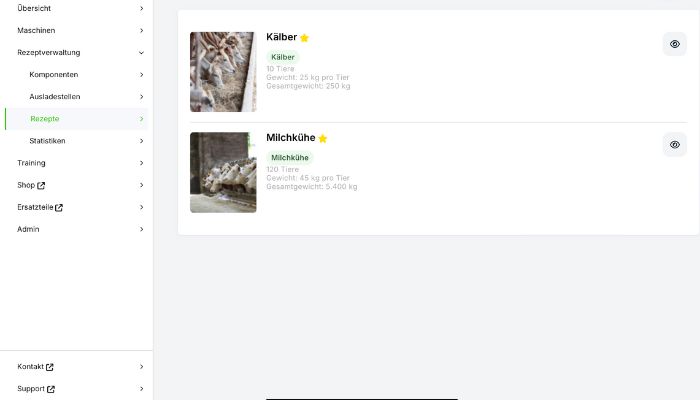

Strautmann Data System (SDS) – is a new platform for all data flows generated by machinery – with its help or within it. One of the main SDS modules for self-propelled feed mixers – feeding software. SDS allows you to create recipes and set unloading points. A clear and user-friendly component and recipe management system can be operated from both a computer and a mobile device. One or more users can access the recipes and perform feeding exactly as instructed. The system can be used by multiple users simultaneously to perform mixing and feeding according to specific requirements. First feed dispensers records all important technical and weighing data and synchronizes them with this system. This allows you to easily analyze, evaluate and adjust the feeding process. SDS is a valuable tool that helps optimize feeding, improve animal productivity and health, while reducing resource consumption.

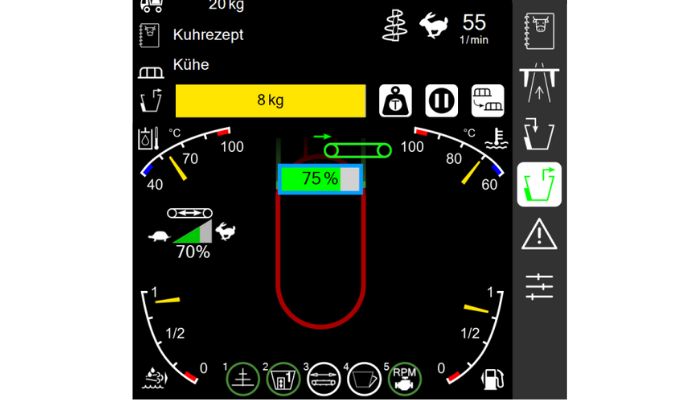

Feed Control system collection mode

Feed Control system travel mode

Feed Control system feed mode

A special advantage for farms with multiple locations is the SDS Premium version: This option allows you to create, manage and analyze data for multiple farms separately and use more recipes. It provides the ability to compare planned and actual indicators, as well as record the working time of each employee and each farm - which helps ensure clear documentation and more accurate billing. In the future, the functionality of SDS will be further expanded - it is planned to integrate maintenance interval management, as well as provide more transparency to customers, for example, in the area of warehouse management.

Universal helper – IMS (Intensive Mix System) mixing auger

Thanks to the patented blade adjustment system, the IMS mixing auger can be precisely adapted to the specific working conditions. The robust and low-maintenance angular gear ensures a long service life even under difficult working conditions.

Longer service life and lower costs

Equipment tailored to your individual needs

Increased safety – rear lateral projection control

Constantly monitor feeding with the Strautmann Data System (SDS)

Powerful milling cutter

Conical funnel behind the cutter

Elevator

Feed collection and transportation

Mineral feed feed valve

Cross conveyor

Cross conveyor with side shift

Cross conveyor with retractable PVC conveyor

Rear unloading behind the wheels on the left or right side

Central rear discharge

Protective cover between the mixing screw and the coaxial reducer

6-cylinder engine

Cabin

Driver's seat

Armrest

The functions can be individually adapted to each user and depending on the operating mode (driving, feeding, unloading).Radio and air conditioning

Feed Control System

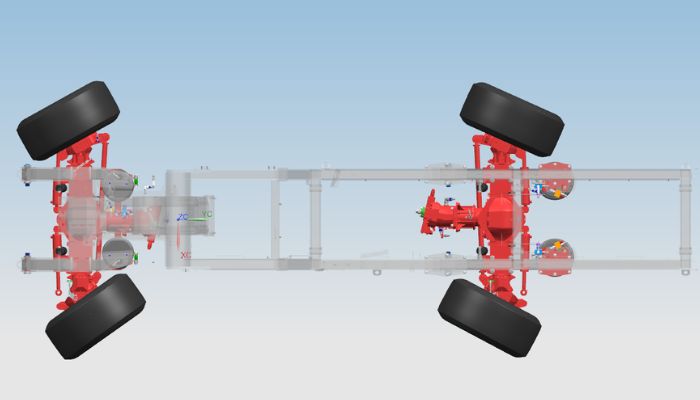

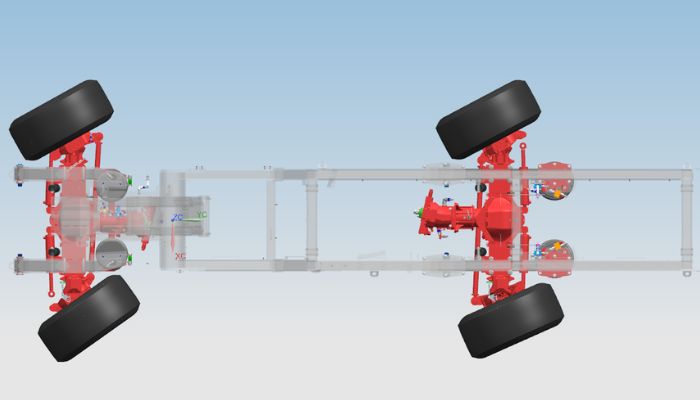

Chassis

Spring suspension

Air suspension

4-wheel drive

Crab-like driving

| Primus 617 | Primus 620 | |

|---|---|---|

| Width with cross conveyor, m | 2,36 | 2,36 |

| Front outer wheel width, m | 2,34 | 2,34 |

| Width with two unloading gates, m | 2,46 | 2,46 |

| Length with front cross conveyor, m | 9,67 | 9,74 |

| Length with rear cross conveyor, m | 9,78 | 9,78 |

| Elevator width, m | 0,58 | 0,58 |

| Cutter diameter, m | 0,61 | 0,61 |

| Collection width, m | 2,00 | 2,00 |

| Maximum collection height, m | 5,50 | 5,50 |

| Distance between the bottom plate and the ground, m | 1,02 | 1,02 |

| Total weight of the base machine from, kg | 14 700 | 15 000 |

| Mixing capacity, m³ | 17,0 | 20,0 |

| Mixing capacity with extension, m³ | 19,0 | 22,0 |

| Wheelbase, mm | 3 970 | 3 970 |

| Vehicle height according to tires | ||

| 435/50 R 19.5 m | 2,74 | – |

| 455/45 R 22.5 m | 2,78 | 3,04 |

A family-run company based in northern GermanyB. Strautmann & Söhne GmbH u. co. KG"has been around for over 85 years.

STRAUTHMANN The factory has developed a wide range of products, especially well suited for livestock farms. The company can offer silage handling equipment for various purposes: silage buckets, silage cutters and silage block cutters for easy silage removal.

STRAUTHMANN Silage block and feed transport trailers have been ensuring fast and easy feed supply for several decades. We also manufacture trailed and self-propelled feed mixers - perfect for preparing physiologically ideal animal feed.

For optimal feed quality, STRAUTHMANN presents grass silage handling equipment. In order to maintain the best quality of feed, the grass loaded into the self-loading trailer is gently but optimally chopped. Customers can purchase tri-axle trailers and dump trucks as well as trailers for convenient feed transportation. Also, manure and universal shakers are available in various sizes. Thus, by creating a high-quality and diverse product offering, STRAUTHMANN the company becomes a competent partner for the farmer.