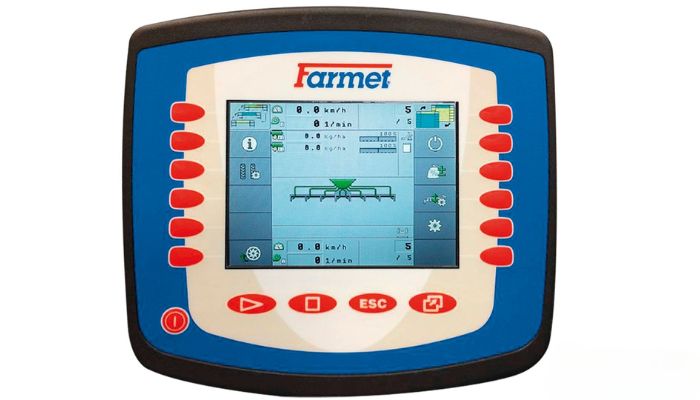

Original Farmet small seed drills are controlled via ISOBUS terminal. They are mounted on cultivators, stubble cultivators, harrows and other tillage implements.

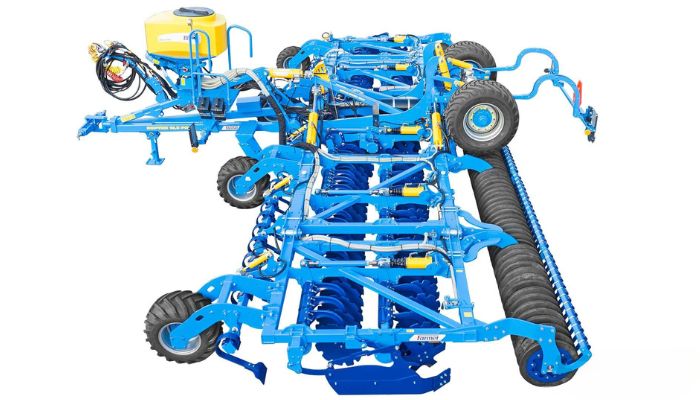

Pneumatic seed drill for implements Micro Drill

Sowing catch crops in one pass

Additional Micro Drill The seed drill can be used both with soil tillage implements and when mounted on seed drills. It allows sowing crops suitable for sowing on the soil surface or under the harrow in a single pass. It can be mounted on the following implements: Falcon PRO seeders, disc harrows Softer and Discomat, tine cultivators Phantom (NS), tine cultivators Triolent, Duolent, Terrix Dual, Terrix Quatro and combination shavers Triton, Triton Heavy.

- Combination of work operations

- Sowing catch crops and grasses

- Protects against soil erosion

- Increasing nitrogen content in the soil

- Limiting weed growth

- Precise seed placement in the transverse direction across the entire working width

- Area counter in hectares, automatic calibration function

- Seed rate can be changed during operation

Different versions of seed drills

Micro Drill drill

Micro Drill PRO seeder

Micro Drill drills can be mounted on the following implements:

- Seeders Falcon Pro

- Disc harrows Softer and Discomat

- Coulter cultivators Phantom (NS)

- Coulter shovels Triolent, Duolent, Terrix Dual, Terrix Quatro

- Combined shavers Triton, Triton Heavy

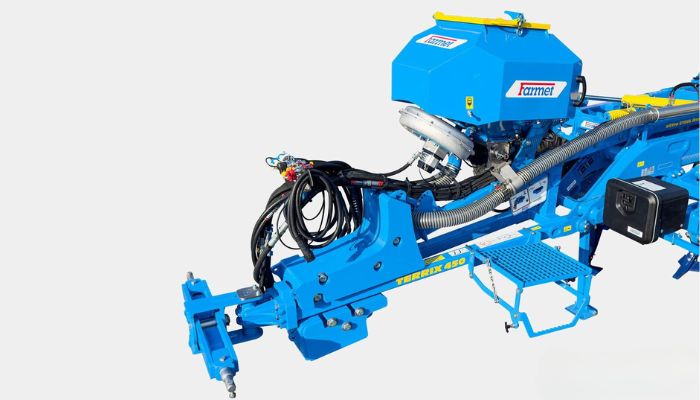

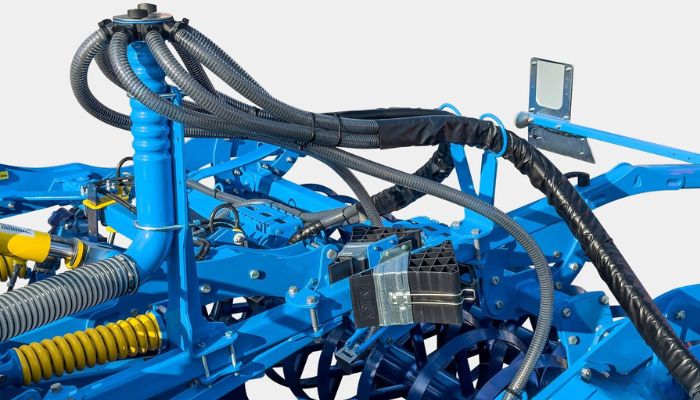

Disc shaver Softer + Micro Drill Hoe shaver Triolent /Duolent + Micro Drill Trench cutter Terrix Quatro + Micro Drill PRO Drill Falcon PRO + Micro Drill PRO The advantage of this device design is – simple adjustment, which ensures high work flexibility and universal application to various conditions. Access to the bunker Steps with a platform ensure convenient access to the bunker. Hydraulic fan The hydraulic fan is used on machines with a working width exceeding 7 meters. Seed distribution The pneumatic seed distribution system is adapted to the design of the machine.

Installation Easy installation for all types of machines.

Seed dispersal The seeds are spread precisely and evenly across the entire width of the machine, regardless of wind conditions.

The seeds are dosed by a seed metering roller, which is mounted under the seed hopper. Before filling the seed hopper with seeds, it is important to choose the correct seed metering roller (coarse or fine), taking into account the characteristics and quantities of the seeds. The standard equipment includes two types of seed metering rollers: for fine seeds (mustard, buckwheat) and for coarse seeds (bellflowers, grasses).

Smartly designed device

Fan selection

Implement width

Drill type

2.1 – 6 m

Double fan with electric drive, 8 seed tubes

2.1 – 7 m

Hydraulically driven fan, 8 seed tubes (optional)

7 – 12 years

Hydraulically driven fan, 16 seed tubes (optional)

Standard equipment

Roller dispensers for all types of seeds

Management

| Micro Drill 300 PRO | Micro Drill 500 PRO | Micro Drill 800 PRO | |

|---|---|---|---|

| Hopper type | pressure | pressure | pressure |

| Dispenser type | roller dispenser | roller dispenser | roller dispenser |

| Hopper capacity, l | 300 | 500 | 800 |

| Dosage range, kg/ha | 1–350 | 1–350 | 1–350 |

FARMETH – the largest manufacturer of agricultural machinery for tillage and sowing in the Czech Republic. The company, founded in 1992, is growing rapidly and devotes much attention and investment to the development of new technologies.

FARMETH agricultural equipment manufactured by this manufacturer must meet the strictest standards of work quality, reliability and durability. All equipment of this manufacturer 36 months warranty provided.

Products and technologies are developed in close collaboration with customers, research institutes and universities. FARMETH The products feature unique technological solutions, some of which are patented. The company seeks not only to improve product quality and create added value, but also to improve production technologies, productivity, and improve occupational safety and environmental protection.

FARMETH The brand is focused on high-quality products and high value. Major investments in modern production management ensure further quality improvement and more efficient production. The goal is to increase the added value of products and strengthen their competitiveness in all markets.