3 ir 4 m darbinio pločio tiesioginės sėjamosios, galinčios sėti visomis sąlygomis

No-till direct seed drills In the fort – successful sowing in all conditions

eForte sėjamosios – patikima, universali sėjamoji užtikrinanti tikslią sėją visomis sąlygomis. Elektrinė pavara ir Isobus valdymo sistema suteikia galimybę tiksliai naudoti sąnaudas priklausomai nuo sąlygų ir automatiškai valdyti sėjos operaciją. Unikali sėjimo aparatų konstrukcija užtikrina tikslų sėklų pasėjimą visomis sąlygomis. Sėklos ir trąšos yra išsėjamos vienu metu tuo pačiu disku, skirtinguose gyliuose. eForte sėjamosiomis sėti galima taikant no-till technology, to minimally processed whether fully worked out soil.

- Direct (No-Till) Seeding

- Can be sown in minimally tilled or tilled soil

- Good seed development and rapid fertilizer uptake

- Large amounts of organic fertilizer can be applied per hectare

- eForte drills with electric drive

- Forte EVO drills with mechanical transmission

- Seeders are maintenance-free

- Low tractor power requirement

- The most versatile control options

The Multiva eForte seed drill's sowing axis is driven by electric motors. The ISOBUS connection provides power for a simple and reliable drive system. The electric motors respond instantly to changes in driving speed and seed rate. The electric drive allows for very high seed rates while driving at normal speed. Using the Multiva SeedPilot controller, the precision farming capabilities of e-seed drills are very broad. Standard equipment includes: variable rate seed, fertilizer and fine seed placement using map and GPS. Also, one of the eForte options is automatic headland management or half-plant shut-off using the section control function.

Multiva Forte seed drills are particularly suitable for farms that use various sowing technologies and deal with different soil conditions.

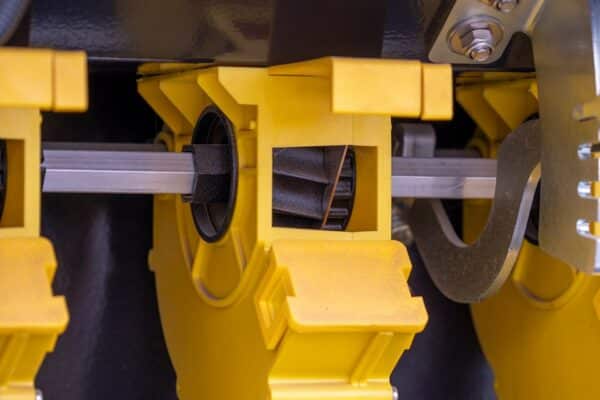

Multiva FX seed drills are designed to provide unprecedented seeding accuracy, durability and maintenance-free hectares. The double-disc discs are large in diameter, highly wear-resistant and maintenance-free. The seed drills have no areas that require lubrication.

Seeds and fertiliser are sown simultaneously, with the same disc, at different depths. The fertiliser is spread from the front of the disc to the bottom of the row. The seeds are spread from the rear of the disc, slightly higher than the fertiliser.

The exact sowing depth is ensured by a clamping wheel for each individual sowing unit. The pressure wheel is located right next to the double-disc sowing disc, allowing for extremely precise adjustment of the sowing depth. The depth always remains constant and unchanged, even on uneven fields. The individual adjustment of each sowing unit with the clamping wheel also has the advantage that changes in the hopper filling level or soil type do not affect the sowing depth. The maximum pressure of the seed drills is even when the hopper is empty. It is recommended to choose front coulters for seed drills intended for sowing in uncultivated soil. Front coulters clean and spread straw accumulations in front of the seeding discs. Placing fertilizer in the same row as the seeds ensures that the seeds will quickly absorb nutrients, resulting in fast, uniform, and strong germination.

The Forte FX seed drills are designed to be extremely durable and maintenance-free. The large-diameter double-disc seed drills are particularly wear-resistant. The seed drill frames are connected to the seed drill by rubber elements, thus protecting against impacts such as stones. The FX seed drills have no lubrication points.

The efficient double-disc coulters, the fact that they are fewer than in other traditional seed drills, and the large wheels result in low resistance, which results in low power requirements and fuel consumption.

Calibration is easy and simple in Multiva seed drills. Calibration in eForte seed drills is carried out using electric motors. All values are automatically presented in the controller, remote control and variable seed and fertilizer rates are standard features. Calibration of the Multiva Forte EVO is carried out simply by using a rotary handle. The stainless steel calibration trays are in two parts for ease of use. They are placed in separate seed and fertilizer tray holders on the left side of the machine. The trays are conveniently stored in the same tray holders for easy use and protection. In the new Multiva seed drills, the fine seed and starter hopper has been completely redesigned. The equipment is integrated into the main hopper, but a movable wall allows even the volume of the fine seed hopper (if not in use) to be used as part of the main hopper. Seeds or starter fertilizers can be placed from the fine seed hopper either into the seed row or behind the coulters at a shallow depth. The fine seed/starter hopper has two chambers. This equipment can be used to sow various seeds. For special light grass seeds, a pendulum hopper is available, which ensures a continuous flow of material. In Multiva eForte seed drills, speed data can be provided by a sensor on the rear axle of the seed drill or by the tractor's ISOBUS. Depending on the specific circumstances, the operator has full control over the appropriate source of speed data. As a result, the seed metering rates always adapt precisely and instantly to changes in forward speed.

Multiva seed drills have open and large-sized metering units, through which very large quantities of material pass. The fertilizer hopper is equipped with sieves, and the metering rollers have aggressive cuts to allow the use of large amounts of organic fertilizer per hectare. The seed drill can be equipped with a fertilizer metering axle, which ensures a uniform flow of material and a high dosing rate. Using Multiva seed drills, it is possible to sow different crops at different depths from different sowing coulters at the same time. For example, beans from the fertilizer hopper and small seeds from the seed hopper. This is possible due to the independent adjustment of the coulter depth. The coulter pressure is hydraulically adjustable from 50 to 250 kg. The coulter pressure is easy to monitor on the SeedPilot terminal. Each coulter has its own pressure cylinder, which ensures a stable sowing depth, regardless of the field surface. The hydraulic coulter pressure system ensures that the coulters operate evenly, resulting in very precise seed placement. Multiva Forte EVO seed drills use a unique drive for seed and fertilizer metering. The drive power is generated using a wheel transmission system. The system ensures precise and continuous power transmission in all conditions. The type of soil or different conditions do not affect the rotation speed of the seed meter. This simple system is reliable and durable. Multiva Forte seed drills have large hoppers, so even with full hoppers it is possible to drive at high speed. The seed drill is easy and uncomplicated to operate, and the operator can focus all his attention on controlling the machine. The middle wall of the hopper can be adjusted, and the tarpaulin rolls up automatically. In eForte seed drills, using electric metering motors, it is possible to remotely optimize the seed and fertilizer supply, depending on the type of soil or conditions. The amount of seed or fertilizer can be easily changed using the controller. SeedPilot ISOBUS remote control. Using GPS, the seed rate can be automatically adjusted based on pre-created maps.Electric drive – innovative features

The most versatile sowing technology on the market

The unique double-disc design and high seeding force of the seed drills allow for no-till sowing technology even in the heaviest soils. When sowing into tilled soil, the seeds are placed optimally precisely and evenly.No-till technology

Minimal tillage technology

Cultivated soil

Universal FX seed drill

Optimal sowing results

Precise adjustment of the sowing depth

Innovative clamping wheel

Maintenance-free seed drills

Quick and easy calibration

Fine seed/starter fertilizer equipment

Precise speed control

Organic fertilizers

Easy adjustment of the seed coulter pressure

Innovative drive

High seeding efficiency

Remote control of fertilizer or seeds

Multiva SeedPilot terminal Intuitive and easy-to-use terminal that increases work efficiency. Multiva SeedPilot ISOBUS terminal The intuitive SeedPilot control system with ISOBUS version, which further increases the control possibilities. The advantage of this SeedPilot control system terminal is the easy connection to all tractors that have ISOBUS. SeedPilot ISOBUS supports TC-BAC and TC-GEO features, which allow the drill to be controlled with pre-set tasks, as well as with pre-defined GPS-based fertilizing maps, for example. Remote dosing eForte In eForte seed drills, the seed and fertilizer supply can be optimized remotely using electric metering motors. The seed or fertilizer amount can be easily changed via the terminal. The SEEDPILOT ISOBUS terminal can automatically adjust the seed rate remotely based on pre-created maps using GPS.

Remote dosing Forte EVO The seed or fertilizer application rate can be adjusted while working. Adjustment is easy and practical from the seed drill control system. With the SeedPilot Isobus control system, remote seed or fertilizer control can be used to insert variable rates based on GPS and map. Pendulum dosing axis With the pendulum metering shaft, light grass seed varieties and light grains such as oats, as well as seeds with micronutrients, can be sown without flow interruptions.

Front compaction wheels The front compaction wheels level and compact the field surface between the tractor wheels, thus preparing the soil faster across the entire width of the machine. Also, the front compaction wheels, integrated into the drawbar, provide greater maneuverability when driving on slopes. Front disc cultivation section The front disc cultivator can be mounted on Forte and Cerex seed drills. The disc cultivator is ideal for preparing the seedbed just before the seeding coulters. The aggressive angle of the discs allows it to be used directly in stubble. Fine seed hopper In the new Multiva seed drills, the fine seed and starter fertilizer hopper is integrated into the main hopper, but a movable wall allows even the volume of the fine seed hopper (if not in use) to be used as part of the main hopper. From the fine seed hopper, seeds or starter fertilizers can be placed either in the seed row or behind the coulters at a shallow depth. Middle markers Rear axles Front ironing board Front straw bales Stone cleaners Track looseners Road lights Tramline markers Work lights and cameraForte drills equipment

The SeedPilot terminal has a high-quality, 7-inch touchscreen. All the necessary information is easily accessible on the main SeedPilot screen.

Easy and clear monitoring of the drill in the status bar. SeedPilot allows you to both monitor the adjustable coulter pressure directly,

both from memory, for example, fertilizer calibration values.

| In the fort | 300 | 400 |

|---|---|---|

| Working width, mm | 3,000 | 4,000 |

| Transport width, mm | 3,000 | 4,090 |

| Hopper loading height, mm | 2,150 | 2,150 |

| Hopper capacity, l | 3,800 | 5,300 |

| Fine seed hopper capacity, l | 370 | 510 |

| Seeding disc pressing force, kg | 50 - 250 | 50 - 250 |

| Seeding coulters, pcs. | 20 | 26 |

| Distance between rows, mm | 150 | 154 |

| Working speed, km/h | 8 - 12 | 8 - 12 |

| Power requirement, HP | 90 | 120 |

| Weight, kg | 4,200 | 5,500 |

| Tires | 250/80-18 | 250/80-18 |

Finnish Agricultural Machinery Factory Dometal Oy's, founded in 1997, produces high-quality, efficient cultivators MULTIVA, adapted to modern farms, paying special attention to product quality, productivity, durability and cost-effectiveness.

MULTIVA Cultivators are a highly advantageous cultivation technology when working in difficult conditions. High-quality cultivators create smooth seedbeds and field surfaces with as few passes as possible.

Even seedbeds are especially important when using standard seed drills. Uneven seedbeds cause problems when using minimal tillage and direct seed drills, as they create uneven seeding depths.

Cultivators are manufactured with the utmost attention to cultivation characteristics, penetration and user comfort.

High-strength steel is used for the production of cultivators – 600 -700 N/mm2.