Heavy-duty tine cultivators for loosening up to 35 cm depth.

TERRIX – heavy tine harrows for full-surface cultivation up to 35 cm deep with intensive mixing

Terrix Quattro

1. Working zone. The working depth can be adjusted over a wide range – from 10 to 35 cm. The optimized four-row rows of working tines ensure very good soil cultivation and intensive mixing with plant residues.

2. Furrow levelling zone. The levelling discs also enhance the incorporation effect of crop residues.

3. Clump breaking and soil compaction zone. Optimal soil compaction ensures good water infiltration and capillary rise of water to the surface.

Terrix Dual

1. First working zone. The first and second rows of tines are arranged sequentially one after the other. The first row, with its optimized geometry, cultivates the soil to a depth of 10–15 cm. The second row of special tines forms deeper cultivated strips beyond the first row – up to a depth of 15–35 cm.

2. First furrow levelling zone. The levelling discs also enhance the incorporation effect of crop residues.

3. Second tillage zone. The third and fourth rows of tines are also arranged sequentially one after the other and cultivate the soil in the intermediate strips after the first tillage zone. The third row of tines cultivates the soil again to a depth of 10–15 cm. The fourth row again forms deeper cultivated strips beyond the third row – up to a depth of 15–35 cm.

4. Second furrow levelling zone. The levelling discs also enhance the incorporation effect of crop residues.

Terrix Quattro

Terrix Dual

High productivity and high quality of work

- An excellent solution for all types of soil, especially suitable for heavy soils.

- High permeability of soil and plant residues.

- High level of mixing and incorporation of crop residues.

- Deep full-surface (Terrix Quatro) or zone (Terrix Dual) cultivation with minimal clod formation.

Wear-resistant steel construction Spring protection

Due to the minimal number of adjustment and lubrication points, the machine's operation and maintenance are extremely simple and easy for every user.

Terrix Quatro PS and Terrix Dual PS heavy-duty tine harrows

Terrix Quatro PS

Terrix Dual PS

Sturdy construction

The time-tested tines are made of high-strength, wear-resistant steel and their tips are covered with carbide plates. The upper part of the tines can be additionally protected with carbide plates or a carbide layer, further extending their service life.

Durable and maintenance-free spring protection with high release force of 550 kg (optional).Easy to use

Easy disconnection and connection of the rear roller – the possibility of working without a rear roller.

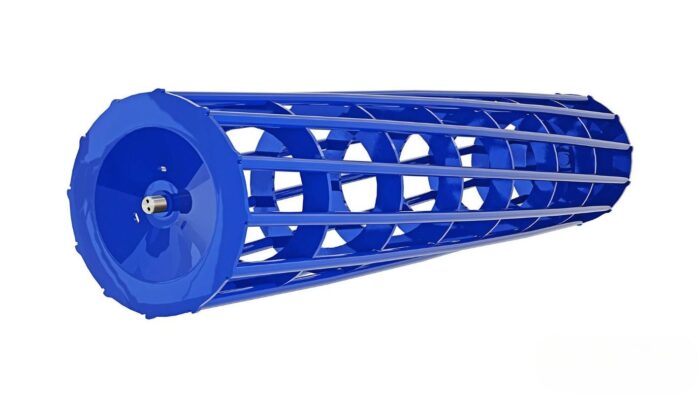

Tubular roller TRS

Diameter – 586 mm

Diameter – 600 mm

The correct selection of the rear roller type, which significantly contributes to the final quality of cultivation, is of utmost importance. The soil is repeatedly compacted by the roller, while at the same time breaking up clods and leveling the surface. The type of roller is selected taking into account the type of soil and the planned use of the machine.

75 MULTICARBIDE PRO Coulter width – 75 mm 75 MULTICARBIDE Coulter width – 75 mm CARBIDE Coulter width – 75 mm 40 CARBIDE Coulter width – 40 mm Left wing Right wing

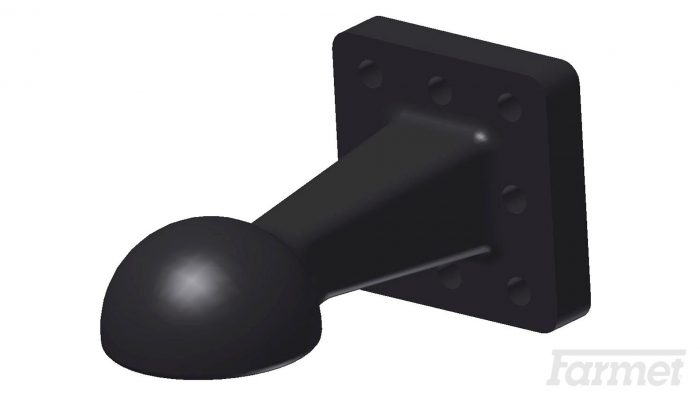

Dual-line single-circuit air brakes TPH categories 3 and 4 Eyelet for lower hitch Ø 50 mm, Ø 70 mm K80 Ø 80 mm.

Reinforced protection of working parts with two springs Electro-hydraulic flow distributor Hydraulic support leg Stiff tow Hydraulic towbar Micro Drill – a micro drill for sowing small seeds.Rollers

Diameter – 600 mm

Weight – 100 kg/m

Diameter – 680/680 mm

Weight – 200 kg/m

Weight – 220 kg/m

Weight – 175 kg/m

Weight – 290 kg/m

Tubular TRS roller Double ring DRR roller LTX roller SDR disc roller V-shaped VR roller Double roller DVR

Crushing ●●○○ ●●●○ ●●○○ ●●●○ ●●●○ ●●●○

Compaction ●●●○ ●●●● ●●●● ●●●● ●●●● ●●●●

Depth support ●●●○ ●●●● ●●●● ●●●● ●●●● ●●●●

Resistance to clogging ●○○○ ●●●● ●●●○ ●●●○ ●●●● ●●●●

Suitability for rocky soils ●●●○ ●●●○ ●●●○ ●●●○ ●●●○ ●●●○

Suitability for wet soils ●○○○ ●●●● ●●●● ●●●● ●●●● ●●●●

Suitability for heavy soils ●●○○ ●●●● ●●●● ●●●● ●●●● ●●●●

Suitability for medium soils ●●●○ ●●●● ●●●● ●●●● ●●●● ●●●●

Suitability for light soils ●●●● ●●●● ●●●○ ●●●○ ●●●● ●●●●

Working tools

Coulter body hardness – up to 55 HRC

Widia plate hardness – up to 92 HRA

Coulter service life – +200–50 %

Coulter body hardness – up to 55 HRC

Widia plate hardness – up to 92 HRA

Coulter service life – +150-400 %

Coulter thickness – 15 mm

Coulter body hardness – up to 55 HRC

Widia plate hardness – up to 92 HRA

Coulter service life – +100–200 %

Coulter thickness – 25 mm

Coulter body hardness – up to 55 HRC

Widia plate hardness – up to 92 HRA

Coulter service life – +100–200%

Diesel consumption – -10%Towing

Other optional equipment

Divides one tractor hydraulic circuit into three separate circuits.

1. A tractor is recommended for towing. Actual pulling force may vary significantly depending on working depth, soil conditions, terrain slope, wear of the working part and its adjustment. 2. Machine weight is stated with LTX roller. 3. Hydraulic brake system alternative / working pressure – 130 ± 5 bar. 4. Transport/Brake system: Observe the applicable national regulations governing the transport of machines on public roads. Check the legal provisions regarding the maximum permissible total weight, axle loads and requirements for the use of the brake system. PS – semi-mounted folding machine

Terrix Quatro 450 PS Terrix Dual 450 PS Terrix Quatro 600 PS Terrix Dual 600 PS

Working width (mm) 4500 4500 6000 6000

Transport width (mm) 3000 3000 3000 3000

Transport height (mm) 3340 3340 4000 4000

Total length (mm) 10500 10500 10500 10500

Working depth (mm) 100-350 100-350 100-350 100-350

Number of tines 23 22 29 30

Distance between tines (mm) 210 420 210 420

Rows of tines 4 4 4 4

Row spacing (mm) min. 940 min. 940 min. 940 min. 940

Tines pressure force (kg) 450/550 450/550 450/550 450/550

Frame clearance (mm) 870 870 870 870

Disc diameter (mm) 460 460 460 460

Productivity (ha/hour) 3,6-5,4 3,6-5,4 4,8-7,2 4,8-7,2

Tractor power (kW/HP) ¹ 225-350 / 300-450 225-350 / 300-450 350-460 / 450-600 350-460 / 450-600

Working speed (km/h) 8─12 8─12 8─12 8─12

Maximum working slope (°) 6 6 6 6

Tire dimensions – for transportation 550/45-22,5 19.0/45-17 550/45-22,5 19.0/45-17

Brake type/distribution ³ ⁴ none / pneumatic none / pneumatic none / pneumatic none / pneumatic

Required pressure (kPa) ³ 5,5 5,5 5,5 5,5

Number of hydraulic circuits / pressure (bar) 4+1 / 200 4+1 / 200 4+1 / 200 4+1 / 200

Number/type of hydraulic connections 8 / ISO 12.5 8 / ISO 12.5 8 / ISO 12.5 8 / ISO 12.5

Tractor hitch TPH cat. 3 and 4; bottom hitch K80; eyelet Ø 50, 70 mm TPH cat. 3 and 4; bottom hitch K80; eyelet Ø 50, 70 mm TPH cat. 3 and 4; bottom hitch K80; eyelet Ø 50, 70 mm TPH cat. 3 and 4; bottom hitch K80; eyelet Ø 50, 70 mm

Weight (kg)² 8400 7300 10200 8800

FARMETH – the largest manufacturer of agricultural machinery for tillage and sowing in the Czech Republic. The company, founded in 1992, is growing rapidly and devotes much attention and investment to the development of new technologies.

FARMETH agricultural equipment manufactured by this manufacturer must meet the strictest standards of work quality, reliability and durability. All equipment of this manufacturer 36 months warranty provided.

Products and technologies are developed in close collaboration with customers, research institutes and universities. FARMETH The products feature unique technological solutions, some of which are patented. The company seeks not only to improve product quality and create added value, but also to improve production technologies, productivity, and improve occupational safety and environmental protection.

FARMETH The brand is focused on high-quality products and high value. Major investments in modern production management ensure further quality improvement and more efficient production. The goal is to increase the added value of products and strengthen their competitiveness in all markets.