High-quality trailed sprayers with a capacity of 4000 - 6500 liters.

Mammoth Sprayer with a 4000 - 6500 liter tank capacity, which can achieve high daily productivity

One of the most popular sprayers in the AGRIO range, which can achieve high daily productivity. These sprayers are used in large farms and agricultural companies. During the off-season, you can do with just the MAMUT sprayer, without additional water delivery to the fields by tankers, thus saving one worker.

High quality and efficient work

- 4000 – 6500 liter capacity.

- Stable working beams in the transverse and longitudinal directions reduce spraying unevenness to a minimum.

- Thanks to their excellent balancing and independent suspension, the booms meet the highest requirements for spraying even on uneven fields.

- The folding ends of the beams allow you to overcome obstacles without driving over them.

- The spacious storage compartment will accommodate all the tools needed for work.

- Safer filling of plant protection products into sprayers with easyFlow system.

- All sprayers are made to order.

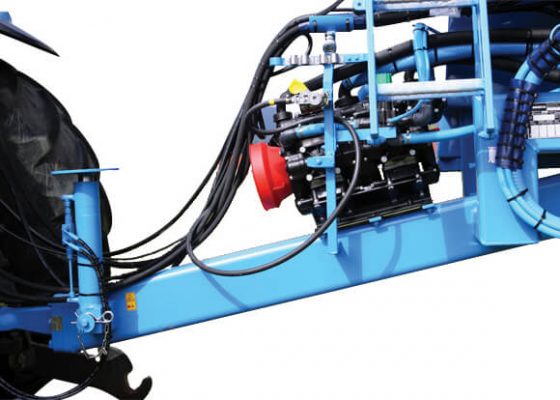

Pneumatic control equipment has the advantage of a simple design – the main control valve also acts as an overpressure protection. This allows the number of hoses to be reduced to a minimum. Simple hose connections are an advantage for flushing and emptying the sprayer, there is no need to use antifreeze, and water can be easily removed from all lines.

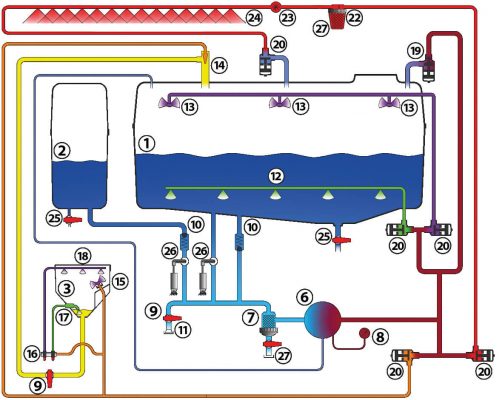

1 – Main tank 16 – 2-lever valve

Adapter for canister Adapter for eco-mixer lid

The round shape of the eco-mixer ensures better wall flushing and, together with the easyFlow quick connection, allows for quick filling with concentrated agents from canisters into the sprayer tank and rinsing the canisters with clean water without the service personnel coming into contact with chemicals. Filling chemicals with the easyFlow quick connection is simple, fast and, most importantly, safe.

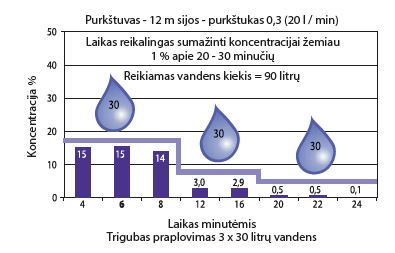

Comparison of conventional flushing with triple flushing and sequential flushing A typical flush takes 20-25 minutes and 90 liters of clean water. Continuous flushing – time 5 minutes and 40 liters of clean water.

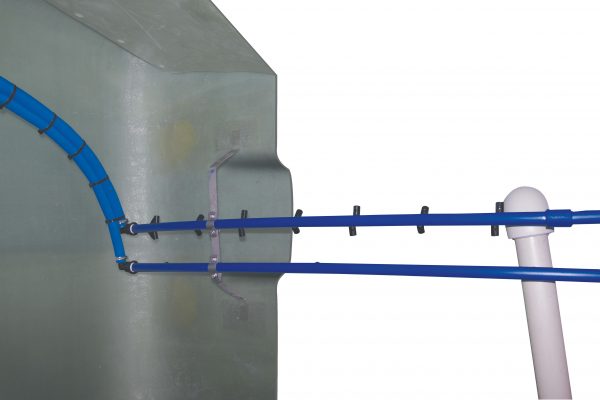

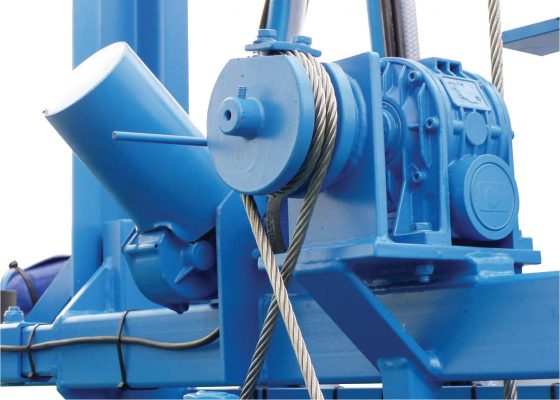

Polyethylene tank. Smooth inner surface, modern design, can be supplemented with partitions upon request. The laminated fiberglass tank has baffles inside that reduce liquid leakage. The inner coating seals the pores in the fiberglass and makes it easier to flush the tank. Eco-faucet Comfort Fill. Made of polyethylene, volume – 60 l, quick coupling can be installed easyFlow for filling protective equipment into the sprayer without contact with the environment. The centrifugal filling pump, with a capacity of 600 l/min, shortens the filling time of the main tank and thus can increase the daily working efficiency of the sprayer. Piston-diaphragm spray pump Annovi Reverberi, with a capacity of 160-500 l/min. Capable of operating for a long time at higher pressure. Stainless steel flushing nozzles, do not get sanded. Central filtration ensures equal pressure in all nozzles. Blue strainer 50 M, green strainer 100 M. Injection mixing with nozzles allows mixing of settled products even after a longer break in work. High-pressure circulation in the booms fills the spray tubes so that the chemicals from the tank reach the nozzles before spraying begins. Simple holder with anti-drip membrane valve. Triple holder with anti-drip membrane valve. The Dual Selejet switches the spray between 2 different sized nozzles while driving, maintaining constant nozzle pressure at different speeds. The Quad Selejet switches the spray between 2, 3 or 4 nozzle sizes on the go. Suction line filter with red 32 M mesh protects the spray pump from damage by larger impurities.Water system features

Water scheme (standard)

Water scheme Topline (standard)

2 – Clean water tank

3 – Eco-mixer

4 – 5-way valve – suction

5 – 5-way tap – pressure

6 – Spray pump

7 – Suction filter

8 – Pressure gauge

9 – 2-way tap

10 – Check valve

11 – Nozzle

12 – Basic mixing

13 – Flushing nozzle

14 – Injector

15 – Canister flushing nozzle

17 – Eco-mixer mixing

18 – Eco-mixer flushing

19 – Control valve

20 – Main valve

21 – Sectional valve

22 – Pressure filter

23 – Flow meter

24 – Beams

25 – Tank Drain

26 – 2-way valve, operated by pneumatic cylinder

27 – Drain tap with Geka connectionSafer filling of plant protection products into sprayers

Eco-mixer Comfort Fill

Consistent internal flushing

• When the pressure drops, air starts to flow from the nozzles.

• The flushing pump is switched on, while the spray pump continues to operate.

• Finish spraying the full concentration preparation on the unsprayed field area.

• After using half of the clean water, turn the sections on and off, the main valve, and briefly open all other lines that still contain the product (filters, mixing flushing).

• The flushing process is complete when all clean water is used.

Including getting on and off the tractor and/or driving over sprayed plants.

The entire process can be controlled only from the tractor.Technological features

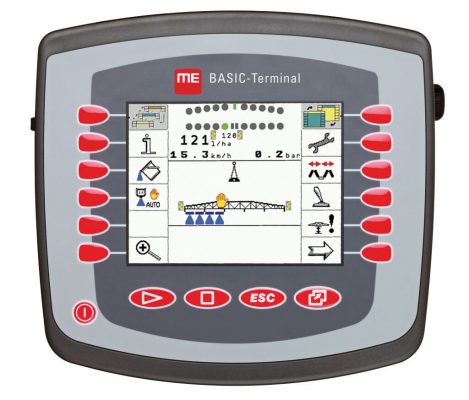

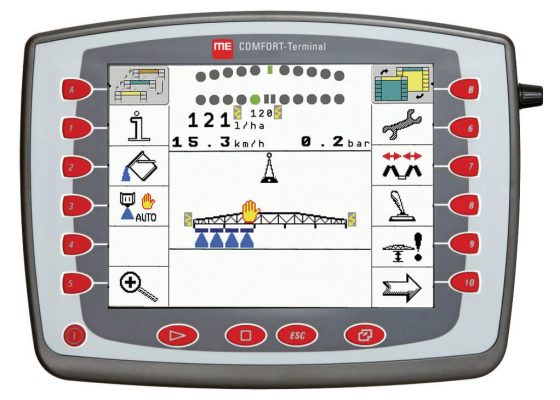

Electronics selection

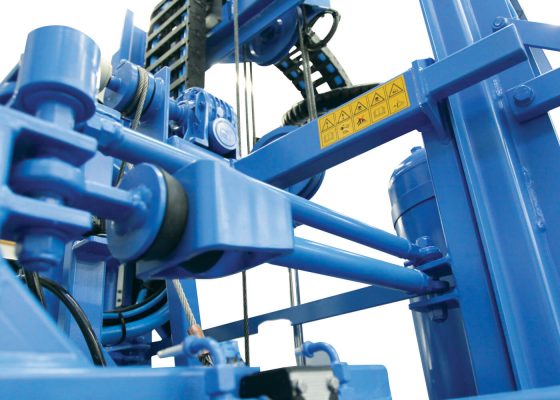

Electrical beam tilt adjustment with a potentiometer makes it easier for the operator to correctly set the beam parallelism and allows for precise travel adjustments. Hydraulic tilt adjustment. Hydraulic shock absorbers dampen the movement of the beams in both directions. Stabilizers reduce forward/backward vibration of the beams. The bar height indicators allow you to automatically level the beams without a computer. Soft vertical shock absorption of the beams is provided by a coiled spring. The beams suspended on the rope are not rigidly connected to the chassis and react minimally to the chassis tilt. Ultrasonic sensors send and receive a signal reflection from the ground (plants). The information is processed by a computer and gives a signal to the beams to level themselves.

The DC Top Super Vario system provides perfect field surface tracking – it allows the boom wings to follow the surface not only when rising but also when falling, independently of each other. This will ensure more precise spraying in difficult field terrain conditions.

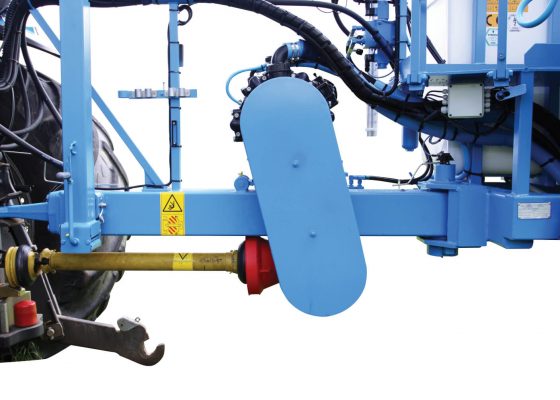

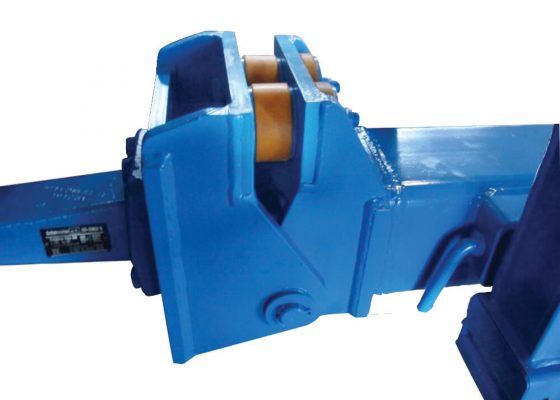

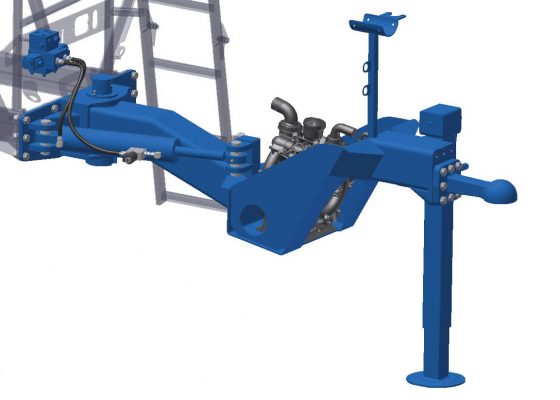

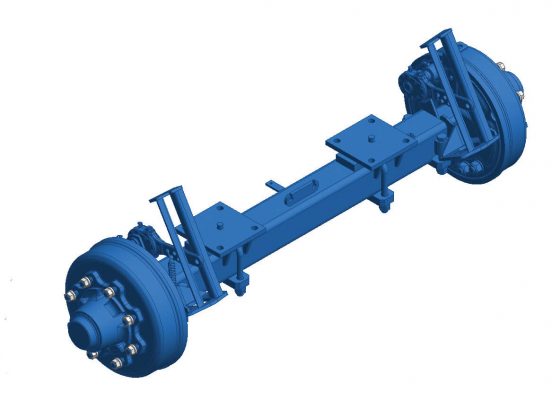

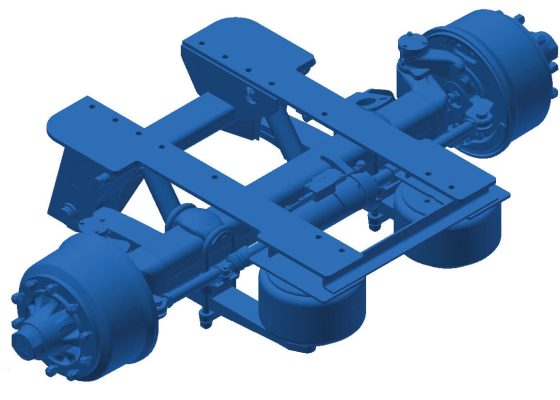

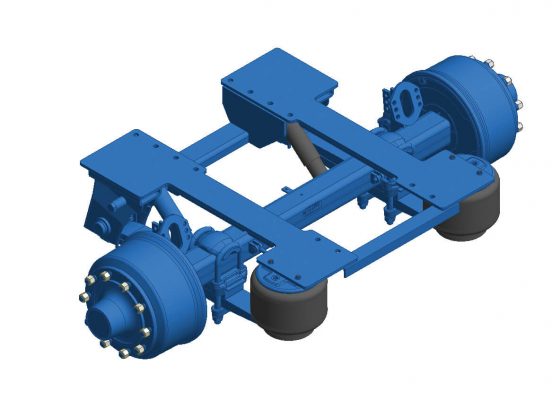

Top mounting creates greater sprayer clearance. The hitch on the K80 sprayer is very useful - the hitch has no play and thus does not increase the forward/backward vibration of the booms. Towbar, pump with mechanical drive. Shock-absorbing drawbar. The lower hitch has a high lifting capacity and allows you to hitch a sprayer up to 8000 l with one axle. The hitch on the K80 sprayer is very useful - the hitch has no play and thus does not increase the forward/backward vibration of the booms. BPW non-suspension axle, adjustable track, up to 7 t. Non-suspension axle ADR, adjustable track, up to 5 t. Non-shock-absorbing, steered axle, BPW up to 10 t. Shock-absorbing, steered axle BPW with air suspension up to 10 t. BPW shock-absorbing axle with air suspension: Three-point hitch attachment.Beams

DC Top Super Copper System

LED beam lighting

Chassis

I var. – up to 6.5 t;

II var. – up to 9 t;

III var. – up to 10 t

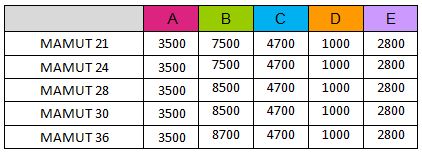

•top hitch •without a computerDimensions

Weight

Beams and tank

Standard equipment

•rigid drawbar

•adjustable track 10 t ADR axle and drawbar suspension

•air and parking brakes

•pump AR 280 for beams up to 30 m

•2 pumps AR 185 for beams over 30 m, driven by cardan gear

•fiberglass laminated tank with baffles and internal flushing, pressure mixing and excess mixing

•manually lowered PE 60 l chemical mixing tank with 4-function control, internal

flushing, level gauge, canister flushing nozzle and mixing nozzle

•15 l capacity for hand washing

•500 l clean water tank with storage compartment and level gauge, central 5-way pressure tap, central 5-way suction tap, external 2ʺ filling and suction, 1 suction + 2 pressure filters

•pneumatic control

•6 working sections up to 30 m

•8 working sections from 30 m

•removable control panel

•beams with active tilt adjustment and potentiometer

•full set of shock absorbers on beams and arms

•stainless steel Ø20 mm pipes in beams with simple nozzle holders every 50 cm

•lights for road traffic

•hydraulics controlled by 2 hydraulic circuits from the tractor

• cardan shaft with large swing joint

EARLY The company, founded in 1993, began its activities with the reconstruction of used sprayers. To date, the factory has expanded significantly, taking a big step forward. Gradually developed EARLY Sprayer group – top quality trailed and self-propelled sprayers, designed with spray booms reaching 36 m, tanks with a capacity of up to 10,000 liters. Advanced solutions based on practice and economic logic are used in production.

The company's development was greatly influenced by cooperation with the German sprayer manufacturer GSB, when in 1993 AGRIO acquired a license for the production of booms, at the same time gaining a lot of valuable information on how to produce a quality sprayer. The company has been improving sprayers for 20 years.

EARLY The uniqueness of the sprayers is the pneumatic control and the spatial booms on the pendulum suspension. The pneumatic control responds quickly, maintenance is very simple and even with intensive use of aggressive liquid fertilizers has an unlimited service life. The booms, thanks to their excellent balancing and independent suspension, meet the highest requirements for spraying even on uneven fields.

The company pays great attention to after-sales service, striving to ensure that the sprayers operate reliably not only during the warranty period, but also throughout their entire service life. The machines are designed to withstand maximum load under intensive use conditions.

Currently EARLY is the largest manufacturer of outdoor sprayers In the Czech Republic, their products are among the best in the world. The 60% sprayers manufactured by this company are sold in the German market, which is characterized by special demands, strict requirements and laws.