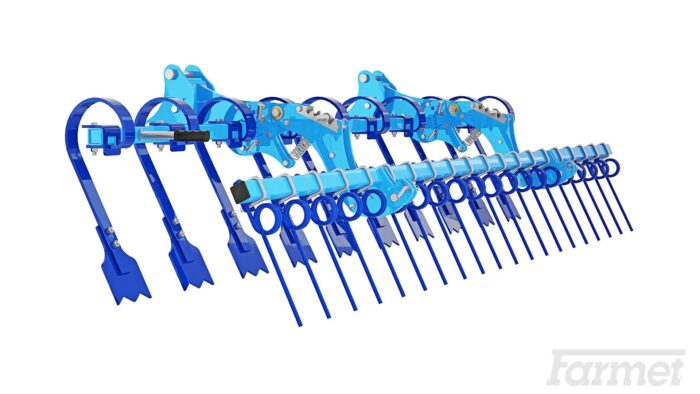

Universal implement for full-surface tillage and cultivation with intensive mixing up to a depth of 15 cm.

Universal implement for full-surface shaving and cultivation with intensive mixing up to 15 cm deep

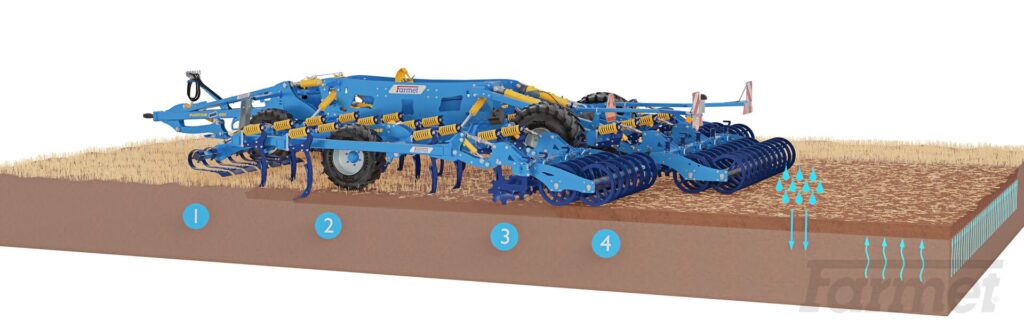

1. Soil surface leveling zone. Suitable for preparing the soil for sowing.

2. Working zone. Working depth 4–15 cm. Optimally shaped tines, arranged in five rows with a small final gap between the tines, ensure even cultivation of the entire surface and intensive mixing of soil and plant residues.

3. Furrow leveling zone. Leveling discs enhance the incorporation effect of crop residues.

4. Clump breaking and soil compaction zone. Optimal soil compaction ensures good water infiltration and soil moisture retention. The rollers are easily removable, so you can work without them.

Trailed 5-row cultivator Fantom PRO easily towed, adjustable working depth implement, suitable for spring, summer and autumn work. The design allows you to start spring work even in wet soil.

High quality and efficient work

- Large working speed – up to 12 km/h.

- Optimal tine setting design allows for easy towing, excellent soil mixing.

- Full-area shaving when using V-shaped coulters.

- Quick coulter attachment system (with a dowel or screw) saves time.

- Simple control and operation

- Quick turnaround using transport wheels.

- Working depth adjustment and convenient Flexi-board control from the tractor cab.

- Maintenance-free working elements with carbide bushings.

- Excellent tine penetration into the soil.

- Because of the depth wheels – precise working depth control even when working without rollers.

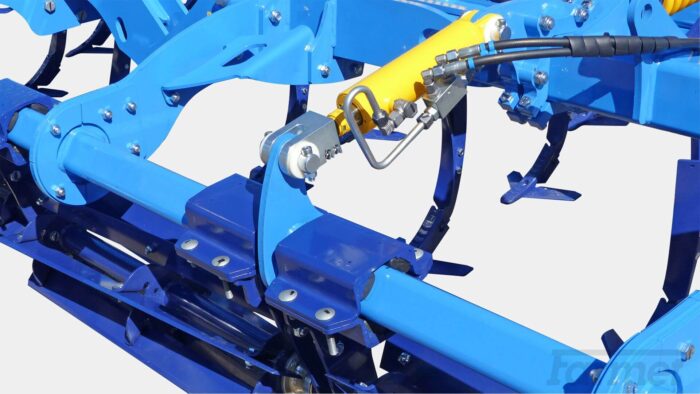

- Hydraulically adjustable roller pressure.

5 rows of tines spaced 190 mm apart on the axis. Optimal arrangement and high ground clearance of 655 mm ensures excellent throughput of crop residues, the cultivator does not clog. The V-shaped and forged coulter attachment system allows for easy and quick replacement. The Fantom PRO has an integrated chassis with transport wheels, making it can be used without rear rollers and rollers. Quick attachment system for rear attachments, so attaching or removing them takes just a few minutes. The rear attachments of the scraper are mounted on a parallelogram. This ensures perfect surface copying, and the modular system also allows replace or completely remove the rear rollers and other equipment. The integrated axle allows the cultivator to be used without rear equipment. The tines, located behind the wheels, cultivate the resulting tracks. Integrated The chassis also ensures maneuverability and quick turning during both work and transport. 655 mm frame clearance ensures optimal permeability and adaptation to outdoor conditions. High-quality soil cultivation and mixing and subsequent incorporation of crop residues with relatively low traction requirements are ensured by replaceable coulters or tines. Changing the tines is quick and easy thanks to the quick-release system. Coulters with carbide plates do not wear out quickly, and the optimal geometry of the tines extends the service life of the cultivator. Behind the tines is smoothing discs, which level the soil surface. In order to achieve an optimal surface structure and good soil compaction, a rear roller is additionally used. The roller pressure is selected - by roller weight or hydraulic pressure. When changing the working depth, the pressure force automatically adjusts so that the soil is always compressed with the same strength. Several types of rear rollers are offered, which ensure soil compaction, clod breaking and surface leveling. The quick-release system makes it easy to replace the rollers, for example with augers, or to completely remove the rear equipment. The rake can be adjusted hydraulically during operation.

Extremely durable materials Massive fastening Wear-resistant steel Spring protection Incorporation of crop residues

Quick tine attachment system

Working depth adjustment Roller pressure

Roller quick mounting system

Maneuverability in the fields Optimal tine arrangement High frame clearance

Folding

Tillage chisels Stubble shaving chisels

Phantom 650 PRO

Excellent crop residue permeability

Can be used even without a rear roller

Versatility

Sturdy construction

Extremely strong, high-quality materials are used for the production of working parts. The frame is precisely sized and made of high-strength steel.

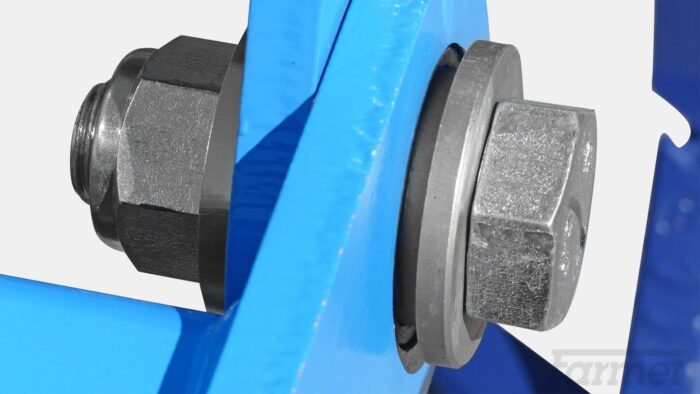

The massive fastening of all rotating parts extends the service life. In addition, this design is easy to update and repair.

The time-tested tips are made of high-strength wear-resistant steel and coated with carbide plates. The option with hard alloy inserts along the entire length of the tip extends their service life even further.

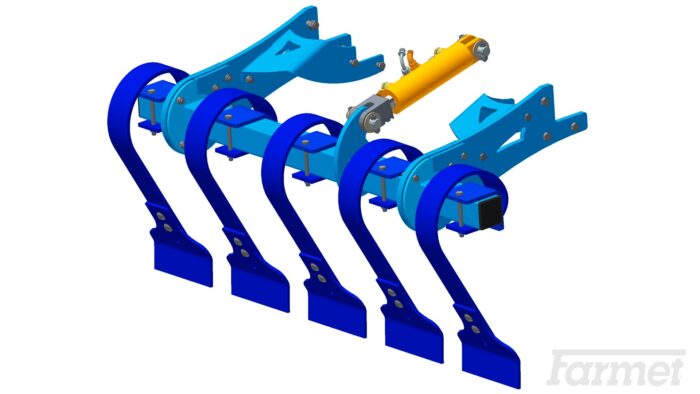

Durable and maintenance-free spring-loaded safety system with high release pressure – up to 310 kg at the tine tip.

Increased frame clearance and wider tine spacing allow the Fantom PRO to be used for full-area stubble shaving with intensive mixing. Plant residues are perfectly incorporated into the soil.

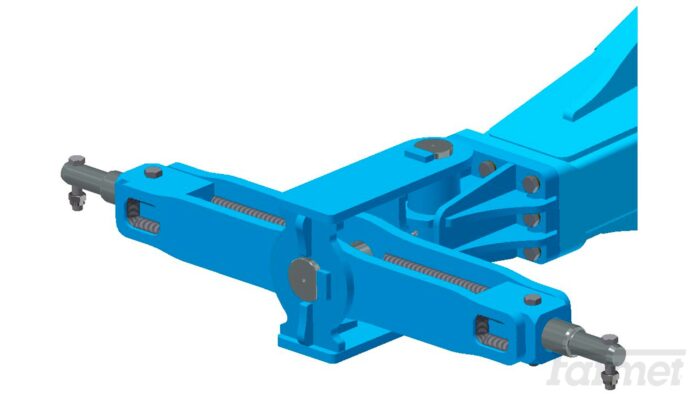

The quick-release tine attachment system (pin, screw) allows for very quick tine replacement.Easy to use

Easy hydraulic adjustment of working depth.

The pressure of the rollers is ensured by their own weight, but can be increased if necessary using a hydraulic system.

Easy disconnection and connection of the rear rollers – allows you to work without the rear rollers as needed.A cleverly designed machine

The tine harrow has an integrated axle, making turns on the headlands easy – transport wheels are used, ensuring smooth and fast maneuvering.

The extended frame allows for tine spacing of 190 mm.

The high frame clearance of 655 mm ensures very good throughput of crop residues.

Flexible attachment ensures perfect surface copying.

The unique folding system allows the 7.9 m working width cultivator to be folded into a transport position of 3 m wide and 4 m high. Fully meets the requirements for road transport.Pre-seeding bed preparation and stubble shaving

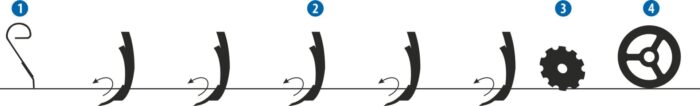

Sturdy tine with chisels for soil cultivation, maximum working depth – 15 cm.

Sturdy tine with chisels for shaving stubble, maximum working depth – 15 cm.

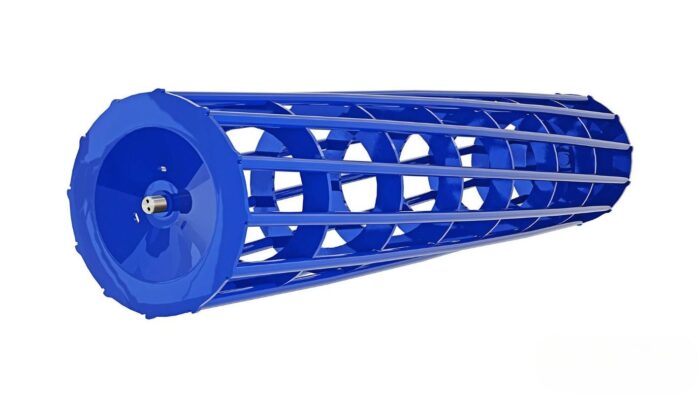

Tubular roller TR

Diameter – 520/520 mm

Diameter – 570/570 mm

The correct selection of the rear roller type, which significantly contributes to the final quality of cultivation, is of utmost importance. The soil is repeatedly compacted by the roller, while at the same time breaking up clods and leveling the surface. The type of roller is selected taking into account the type of soil and the planned use of the machine.

Flexi-board + harrow L-BH

50 MULTICARBIDE Coulter width – 50 mm 50 CARBIDE Coulter width – 50 mm 40 CARBIDE with interchangeable blades Coulter width – 280 mm Fork 230 mm Coulter width – 230 mm CARBIDE

Flexi-cut

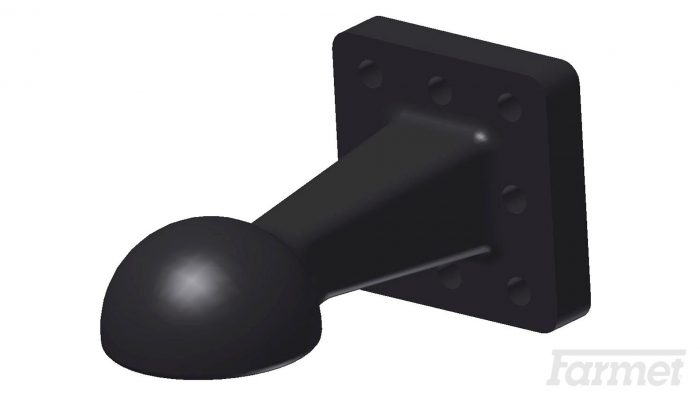

TPH category 3 Pin set for TPH hitch system, category 4 Swivel towing eye Ø 50 mm, Ø 70 mm K80 Ø 80 mm.

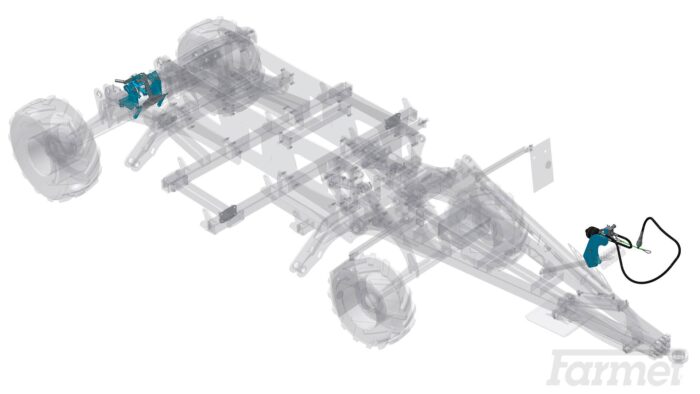

Electro-hydraulic flow distributor Hydraulic brakesRollers

Diameter – 500 mm

Weight – 90 kg/m

Diameter – 500/500 mm

Weight – 170 kg/m

Weight – 165 kg/m

Weight – 175 kg/m

Weight – 180 kg/m

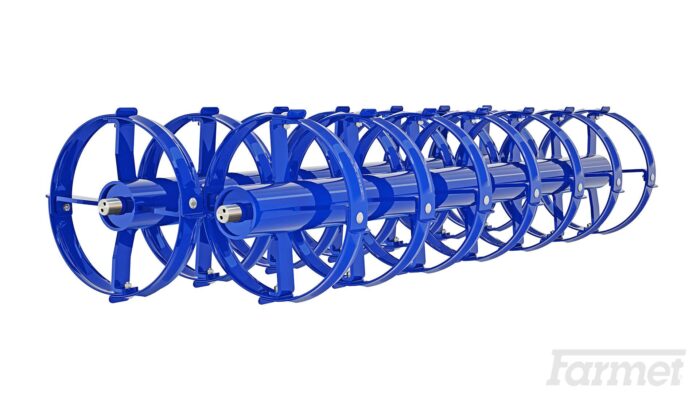

Double ring DRR roller Double smooth roller DFR Double studded roller DSR Tubular roller TR Disc roller SDR Double V-shaped annular roller DVR

Crushing ●●●○ ●●●○ ●●○○ ●●○○ ●●●○ ●●●○

Compaction ●●●● ●●●● ●●●○ ●●●○ ●●●● ●●●●

Depth support ●●●● ●●●● ●●●● ●●●○ ●●●● ●●●●

Resistance to clogging ●●●● ●●●● ●●●● ●○○○ ●●●○ ●●●●

Suitability for rocky soils ●●●○ ●●●○ ●●●○ ●●●○ ●●●○ ●●●○

Suitability for wet soils ●●●● ●●●● ●●●● ●○○○ ●●●● ●●●●

Suitability for heavy soils ●●●● ●●●● ●●●● ●●○○ ●●●● ●●●●

Suitability for medium soils ●●●● ●●●● ●●●● ●●●○ ●●●● ●●●●

Suitability for light soils ●●●● ●●●● ●●●○ ●●●● ●●●○ ●●●●

Harrows

Weight – 62.5 kg/m

Flexi-board + harrow Three-row harrow + rod roller

Crushing ●●○○ ●●●●

Compaction ●○○○ ●○○○

Resistance to clogging ●●●● ●●○○

Suitability for rocky soils ●●○○ ●●○○

Suitability for heavy soils ●●○○ ●●○○

Suitability for medium soils ●●●● ●●●○

Suitability for light soils ●●●● ●●●●

Working tools

Coulter body hardness – up to 55 HRC

Widia plate hardness – up to 92 HRA

Coulter service life – +400–600 %

Coulter thickness – up to 55 HRC

Coulter body hardness – up to 92 HRA

Hardness of the weld – up to 60 HRC

Coulter service life – +400-600 %

Coulter body width – 43 mm

Coulter thickness – 6 mm

Coulter body hardness – up to 55 HRC

Carbide plate hardness – up to 92 HRA

Coulter thickness – 8 mm

Coulter body hardness – up to 55 HRCFront screed sections

Towing

Other optional equipment

Divides one tractor hydraulic circuit into three separate circuits.

| Phantom 650 PRO | Phantom 800 PRO | Phantom 850 PRO | Phantom 1050 PRO | Fantom 1250 PRO | |

|---|---|---|---|---|---|

| Type | trailed | trailed | trailed | trailed | trailed |

| Working width, mm | 6,550 | 8,050 | 8,450 | 10,350 | 12,250 |

| Transport width, mm | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 |

| Transport height, mm | 3,550 | 4,000 | 4,275 | 3,700 | 4,000 |

| Total length, mm | 9,900 | 9,900 | 9,900 | 10,400 | 10,400 |

| Working depth, mm | 40–150 | 40–150 | 40–150 | 40–150 | 40–150 |

| Tines, pcs. | 35 | 43 | 45 | 57 | 67 |

| Distance between tines, mm | 190 | 190 | 190 | 190 | 190 |

| Number of tine rows, pcs. | 5 | 5 | 5 | 5 | 5 |

| Distance between rows, mm | 790 | 790 | 790 | 790 | 790 |

| Fork pressure force, kg | 310 | 310 | 310 | 310 | 310 |

| Support wheels, pcs. | 4 | 6 | 6 | 8 | 8 |

| Transport wheels, pcs. | 2 | 2 | 2 | 2 | 2 |

| Frame clearance, mm | 655 | 655 | 655 | 655 | 655 |

| Productivity, ha/hour | 5.2–7.8 | 6.4–9.6 | 6.8–10.2 | 8.4–12.6 | 10.0–15.0 |

| Tractor power, kW/HP | 200-300 / 270-405 | 230-350 / 310-475 | 245-370 / 330-495 | 295-400 / 400-550 | 400-440 / 550-675 |

| Working speed, km/h | 8–12 | 8–12 | 8–12 | 8–12 | 8–12 |

| Maximum working slope, ° | 6 | 6 | 6 | 6 | 6 |

| Hydraulic connections/pressure, bar | 5–6 / 200 | 5–6 / 200 | 5–6 / 200 | 5–6 / 200 | 5–6 / 200 |

| Number/type of quick-connect devices | 12 / ISO 12.5 | 12 / ISO 12.5 | 12 / ISO 12.5 | 12 / ISO 12.5 | 12 / ISO 12.5 |

| Towing | TPH category 3; pin Ø 50, 70 mm; ball joint K80 | TPH category 3; pin Ø 50, 70 mm; ball joint K80 | TPH category 3; pin Ø 50, 70 mm; ball joint K80 | pin Ø 50, 70 mm; ball joint K80 | pin Ø 50, 70 mm; ball joint K80 |

| Weight, kg | 8 300 | 9 300 | 9 500 | 12 700 | 13 800 |

FARMETH – the largest manufacturer of agricultural machinery for tillage and sowing in the Czech Republic. The company, founded in 1992, is growing rapidly and devotes much attention and investment to the development of new technologies.

FARMETH agricultural equipment manufactured by this manufacturer must meet the strictest standards of work quality, reliability and durability. All equipment of this manufacturer 36 months warranty provided.

Products and technologies are developed in close collaboration with customers, research institutes and universities. FARMETH The products feature unique technological solutions, some of which are patented. The company seeks not only to improve product quality and create added value, but also to improve production technologies, productivity, and improve occupational safety and environmental protection.

FARMETH The brand is focused on high-quality products and high value. Major investments in modern production management ensure further quality improvement and more efficient production. The goal is to increase the added value of products and strengthen their competitiveness in all markets.