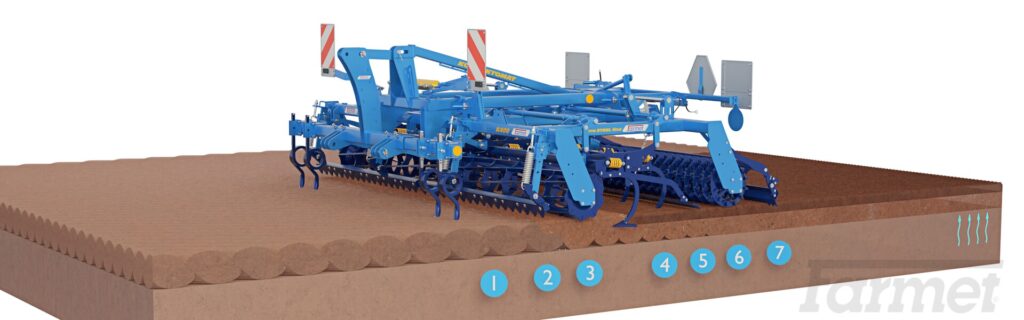

2.6–6 meter suspended germinators are designed to prepare the soil after plowing.

Kompaktomat N-NS germinators are time-tested machines designed for soil preparation after plowing. In one pass, the soil is ideally cultivated to a condition suitable for sowing.

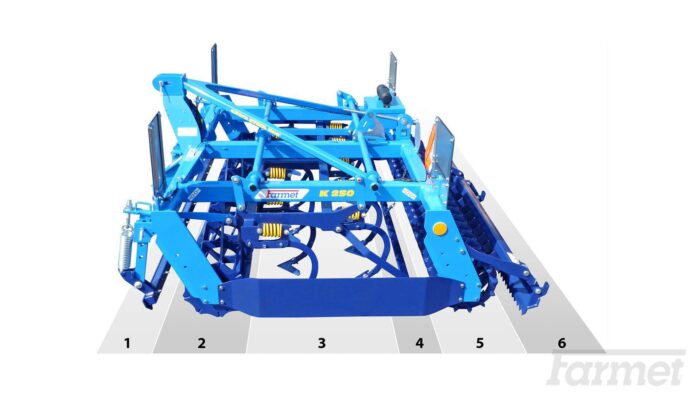

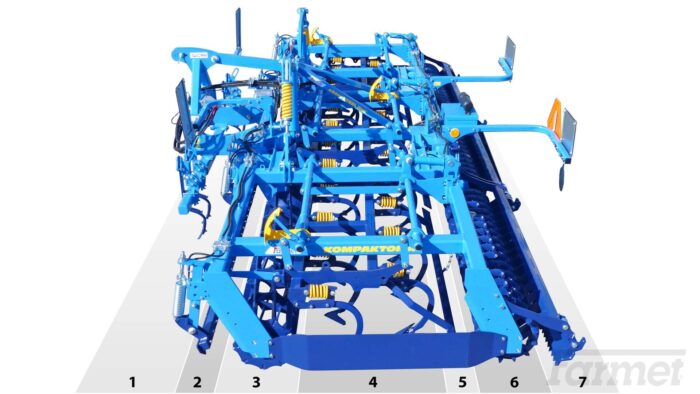

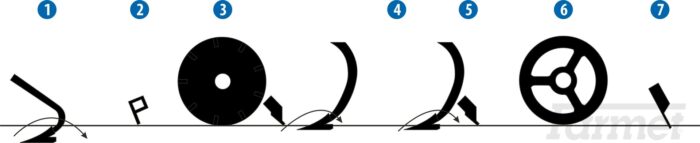

1. Tractor track loosening zone. Precise track cultivation ensures even crop germination.

2. Primary soil leveling zone. A thoroughly leveled soil surface ensures even further compaction and soil cultivation.

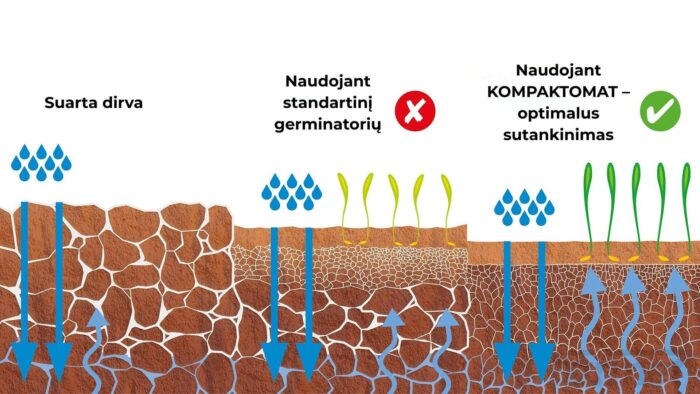

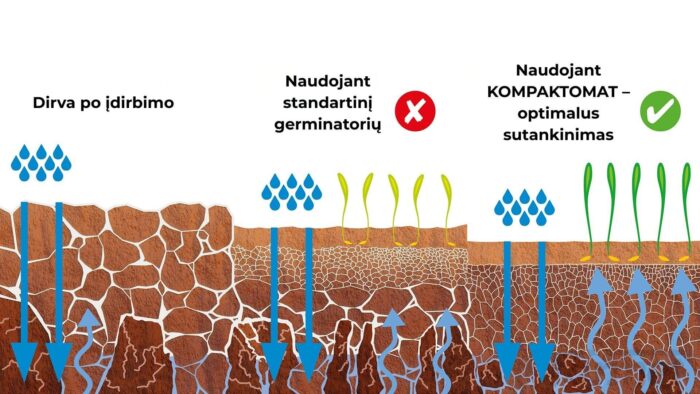

3. Soil compaction zone with the front roller. The front roller breaks up clods on the soil surface, at the same time compacting the soil and restoring its capillarity.

4. Seedbed formation zone. The tine section loosens the soil to a set depth. This depth should correspond to the depth of the future sowing. The tine with arrow tines ensures full surface shaving and weed control.

5. Furrow leveling area behind the tine section.

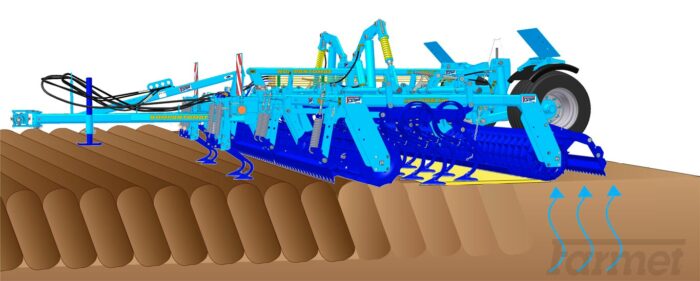

6. Soil compaction zone with rear roller. The roller finely crushes clods and ensures final soil compaction to fully restore its capillarity. Intensive capillary movement of water to the surface ensures good plant germination even in dry periods.

7. Final soil leveling zone. The rear leveling board ensures perfect soil leveling for subsequent sowing.

High quality and efficient work

- 7 operations are performed simultaneously.

- Large working speed – up to 14 km/h.

- Creates proper soil structure and compacts it, ensuring even cultivation.

- Precise setting of the working depth of the coulters ensures very good seedbed preparation.

- Automatic tine protection guarantees uninterrupted operation.

- Excellent levelling of uneven fields with optimal soil compaction.

6. The rear leveling section levels the surface. 7. The rear leveling section levels the surface.

High working speed allows you to achieve high work productivity even when working with the Kompaktomat unit with a smaller working width. Thanks to the extremely well-designed design and the optimal weight of the Kompaktomat, the soil is cultivated in one pass after ploughing. Several working operations are performed in one pass, during which the soil surface is leveled and compacted at the selected depth. The soil capillarity is restored and the sowing base is formed at the required depth. The clods are finely crushed. The germinator controls are designed to ensure maximum worker safety. Simple but high-quality construction with minimal maintenance requirements.

Quality cultivation

Used for production extremely high quality materials and applies eXtra STEEL line The technology guarantees long-term use even in the most difficult conditions.

Tine protection

Working depth

View the differences in each section Optional equipment Section AL Section CF Section APCompactor K 250 N

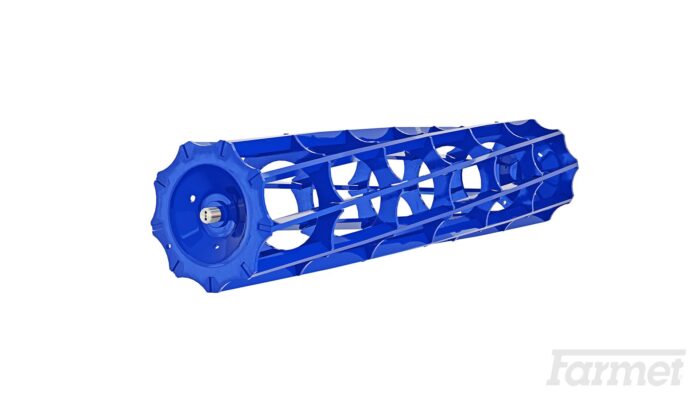

Compactor K 600 NS

Excellent surface smoothing, clod breaking

Prepares the soil for sowing in one pass

Minimum maintenance requirements

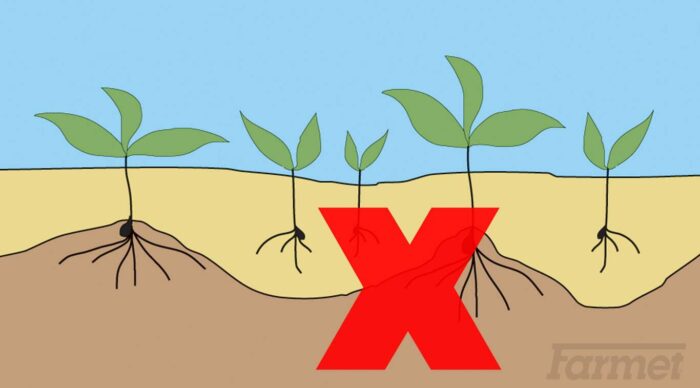

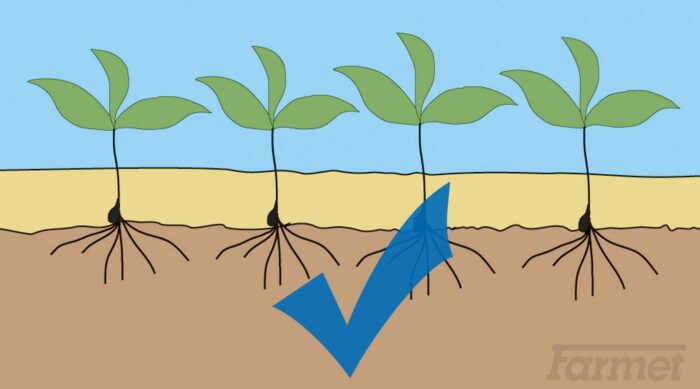

Uniform soil cultivation using the Kompaktomat germinator results in uniform plant germination.Excellent compaction → ensures water absorption and capillary rise of water to the surface

Sturdy construction

Automatic tine protection.Easy to use

Setting the working depth of the coultersTine sections

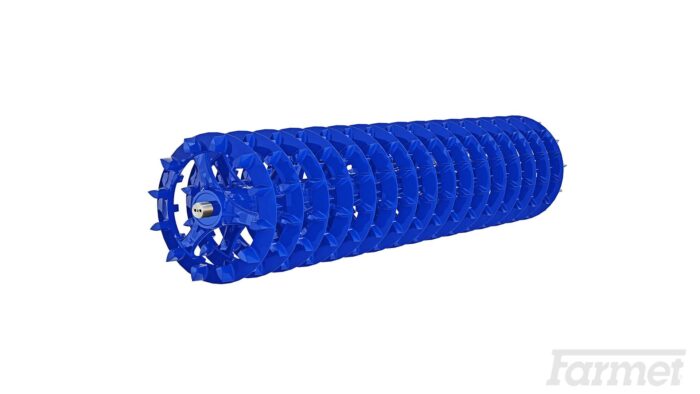

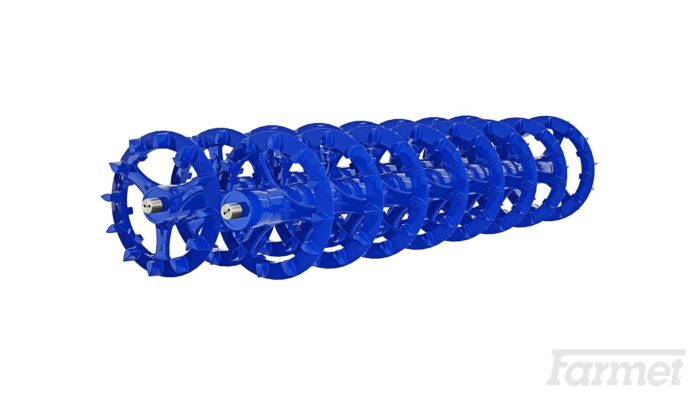

Ring roller RR Can be used as a front and rear roller.

Weight – 133 kg/m Can only be used as a rear roller.

Diameter – 400 mm Can only be used as a rear roller.

Diameter – 400 mm Can be used as a front and rear roller.

Diameter – 400 mm Can be used as a front and rear roller.

The correct selection of the rear roller type, which significantly contributes to the final quality of cultivation, is of utmost importance. The soil is repeatedly compacted by the roller, while at the same time breaking up clods and leveling the surface. The type of roller is selected taking into account the type of soil and the planned use of the machine.

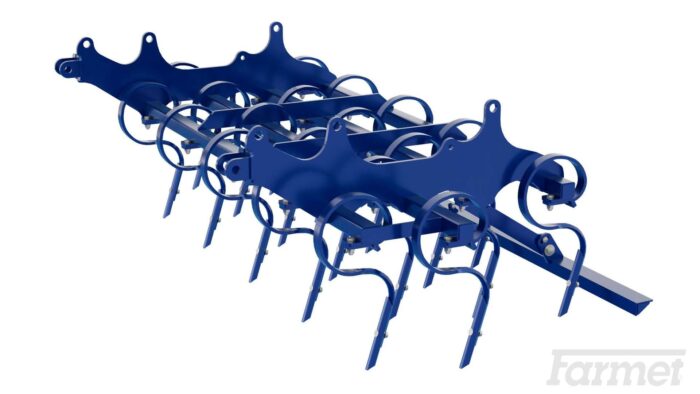

Kompaktomat boom tine DURA+ Designed for AL / AP sections and CA wheel mark eradicators. CARBIDE chisel For the CF section. Double-sided chisel For the CF section. Double-sided chisel Designed for CC track looseners.

AP section Universal tillage section with 27 cm wide tine arms arranged in two rows. The tines are mounted on tine holders with a geometry that improves the throughput of crop residues. This tine section is suitable for fields with a lot of chopped crop residues, as well as for heavy soils. Comes standard with a height-adjustable levelling beam behind the tines.

AL section The section consists of 27 cm wide tine arms arranged in two rows. This section is suitable for light soils without crop residues. Comes standard with a height-adjustable levelling beam behind the tines

CF section The section consists of 3.5 cm wide narrow tines arranged in four rows. Ideal for spring soil preparation or heavy soils where raising moist soil to the surface is undesirable. Standard equipped with a leveling beam behind the tines

Track cultivators CC Kompaktomat K 500 NS + K 600 NS The design of the mounted cultivator does not allow the direct mounting of the wheel mark eradicators on the cultivator itself. Therefore, it is possible to additionally install a frame with wheel mark eradicators between the tractor and the cultivator. The wheel mark eradicators design is connected to the machine using a three-point suspension system.

Track cultivators with double-sided tines CC Kompaktomat K 300 N + K 400 NS Automatic release tractor wheel mark eradicators with double-sided tines. Suitable for heavy soils where there is a risk of raising wet clods to the surface.

Fixed ironing section Automatically releasing levelling beam with toothed profile. Robust construction ensuring precise levelling of large clods. FL = fixed mechanical slide, FH = fixed hydraulic slide.

Flexi-board ironing board Automatically unprotected levelling beam, consisting of individual flexible segments. Better clod breaking. L = Flexi-board, FB = hydraulically operated Flexi-board.

The screed blades work as a single unit, providing better stability.

Rear leveling beam Passive soil levelling behind the rear roller. The aggressiveness of the levelling strip is adjusted by means of rotary stops. Can be used with all types of rear rollers. Rod roller RF Active crushing of remaining clods behind the rear roller. Crosskill roller RFC Active crushing of remaining clods behind the rear roller.Rollers

Diameter – 400 mm

Weight – 115 kg/m

It works well in all types of soils, maintains good working depth, and is suitable even for wetter soils.

Excellent work in light, medium and heavy soils, high-quality compaction and clod breaking.

Weight – 185 kg/m

Distance between roller rows – 274 mm

Excellent work in light, medium and heavy soils, high-quality compaction and clod breaking. Compared to the Crosskill roller, it ensures more intensive clod breaking.

Weight – 70 kg/m

High-quality clod breaking. Suitable for use in wet conditions.

Weight – 63 kg/m

Good clod breaking. Not very suitable for wet conditions.

Crosskill roller CR Double Crosskill roller DCR Beam roller BR Spiral beam roller SB Ring roller RR

Crushing ●●●● ●●●● ●●●○ ●●●○ ●●○○

Compaction ●●●● ●●●● ●●●○ ●●●○ ●●●●

Depth support ●○○○ ●●○○ ●●●○ ●●●○ ●●●●

Resistance to clogging ●●●○ ●●●● ●●○○ ●●●○ ●●●●

Suitability for rocky soils ●●○○ ●●○○ ●●●○ ●●●○ ●●●○

Suitability for wet soils ●●○○ ●●●○ ●○○○ ●●●○ ●●●●

Suitability for heavy soils ●●●○ ●●●● ●●○○ ●●○○ ●●●○

Suitability for medium soils ●●●● ●●●● ●●●○ ●●●○ ●●●○

Suitability for light soils ●●●● ●●●● ●●●● ●●●● ●●●○

Working tools

Tine sections

AL AL-L CF CF-L AP AP-L AL4

Number of tine rows, pcs. /

distance between rows, mm2 / 400 2 / 510 4 / 240 4 / 265 2 / 490 2 / 600 4 / 270

Leveling beam behind the tines ●●●● ●●●● ●●●● ●●●● ●●●● ●●●● ●●●●

Full surface cultivation ●●●● ●●●● ●●○○ ●●○○ ●●●● ●●●● ●●●●

Suitability for light soils ●●●● ●●●● ●●●● ●●●● ●●●● ●●●● ●●●●

Suitability for medium soils ●●●○ ●●●○ ●●●○ ●●●○ ●●●● ●●●● ●●●●

Suitability for heavy soils ●●●○ ●●●○ ●●●○ ●●●○ ●●●● ●●●● ●●●●

Suitability for rocky soils ●●●○ ●●●○ ●●●○ ●●●○ ●●●● ●●●● ●●●○

Suitability for wet soils ●●○○ ●●○○ ●●●● ●●●● ●●○○ ●●○○ ●●●○

Resistance to clogging ●●○○ ●●○○ ●●●○ ●●●○ ●●●○ ●●●○ ●●●○

Track looseners

Ironing sections

Rear sections

| Compact machine K 250 N | Compact machine K 300 N | Compact machine K 400 NS | Compact machine K 500 NS | Compact machine K 600 NS |

|

|---|---|---|---|---|---|

| Working width, mm | 2 580 | 3 000 | 4 000 | 5 000 | 6 000 |

| Transport width, mm | 2 580 | 3 000 | 3 000 | 3 000 | 3 000 |

| Total length, mm | 2 640 | 2 640 | 2 930 | 3 200 | 3 200 |

| Working depth, mm | 0-100 | 0-100 | 0–100 | 0-100 | 0-100 |

| Arrow tines – AL section, pcs. | 11 | 13 | 18 | 23 | 27 |

| Forged tines – CF section, pcs. | 26 | 30 | 39 | 49 | 59 |

| Arrow tines – AP section, pcs. | 11 | 12 | 16 | 23 | 24 |

| Productivity, ha/hour | 2–3 | 2.2–3.2 | 3–4 | 5–6 | 6–7.2 |

| Tractor power, kW/HP | 55/75 | 70/95 | 90/125 | 120/165 | 130/180 |

| Working speed, km/h | 10–14 | 10–14 | 10–14 | 10–14 | 10–14 |

| Maximum working slope, ° | 11 | 11 | 6 | 6 | 6 |

| Hydraulic connections/pressure, bar | 0 | 0 | 1–3 / 200 | 1–3 / 200 | 1–3 / 200 |

| Number/type of hydraulic connection pairs | 0 | 0 | 2-6 / ISO 12.5 | 2-6 / ISO 12.5 | 2-6 / ISO 12.5 |

| Towing | TPH Category 2 | TPH Category 2 | TPH Category 3 | TPH Category 3 | TPH Category 3 |

| Lower suspension link spacing (measured from link axis centers), mm | 870 ± 1.5 | 870 ± 1.5 | 1010 ± 1.5 | 1010 ± 1.5 | 1010 ± 1.5 |

| Diameter of holes in the lower suspension links for suspension pins, mm | 29 | 29 | 37,5 | 37,5 | 37,5 |

| Diameter of the upper suspension connection hole for the suspension pin, mm | 26 | 26 | 32,5 | 32,5 | 32,5 |

| Weight, kg | 1 155 | 1 510 | 2 670 | 3 150 | 3 500 |

FARMETH – the largest manufacturer of agricultural machinery for tillage and sowing in the Czech Republic. The company, founded in 1992, is growing rapidly and devotes much attention and investment to the development of new technologies.

FARMETH agricultural equipment manufactured by this manufacturer must meet the strictest standards of work quality, reliability and durability. All equipment of this manufacturer 36 months warranty provided.

Products and technologies are developed in close collaboration with customers, research institutes and universities. FARMETH The products feature unique technological solutions, some of which are patented. The company seeks not only to improve product quality and create added value, but also to improve production technologies, productivity, and improve occupational safety and environmental protection.

FARMETH The brand is focused on high-quality products and high value. Major investments in modern production management ensure further quality improvement and more efficient production. The goal is to increase the added value of products and strengthen their competitiveness in all markets.