Popular disc harrows for shallow stubble cultivation up to 13 cm.

SOFTER – mounted and trailed disc harrows for shallow stubble cultivation

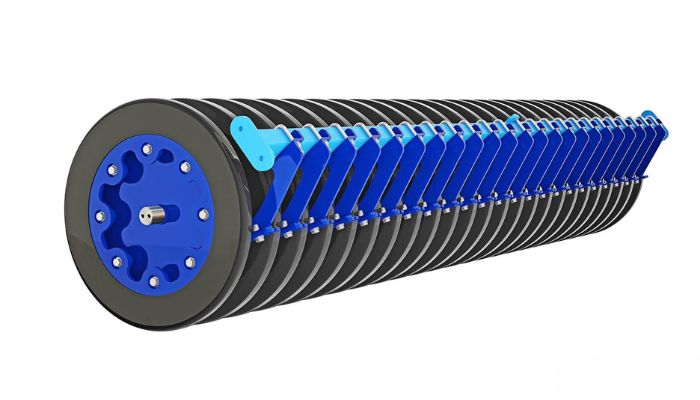

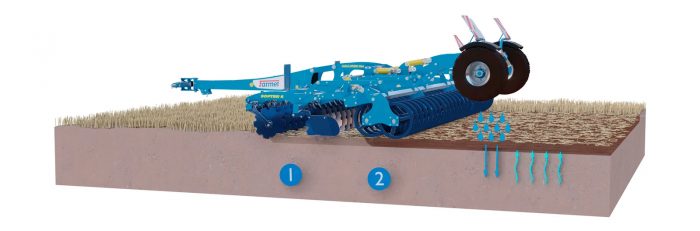

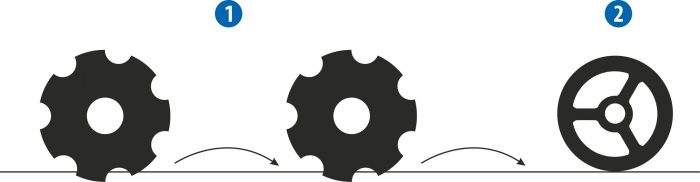

1. Full-area shaving zone. The double disc section with aggressive geometry ensures perfect shaving over the full area at a depth of 3.5 - 13 cm with intensive mixing of plant residues. The disc section also distributes plant residues well over the entire working area.

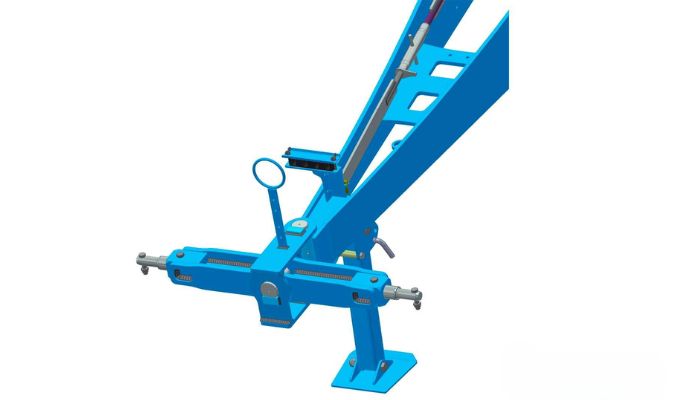

2. Clump breaking and soil compaction zone. Optimal soil compaction ensures good water infiltration and soil moisture retention.

High quality and efficient work

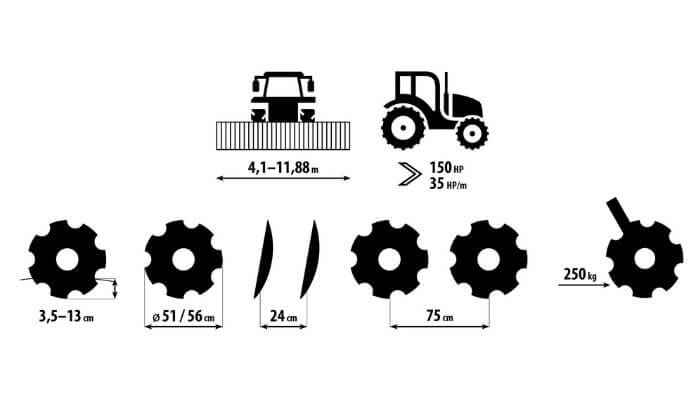

- Large working speed – up to 15 km/h.

- The cut discs easily penetrate the soil and mix it intensively.

- Disc angle, high pressure force for each disc, ensures uncompromising penetration even in the heaviest or most dry soil and excellent tillage of the soil.

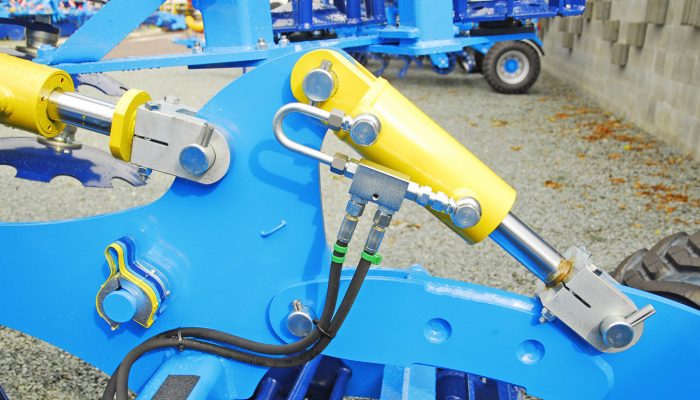

- High quality rubber couplings for optimal disc working angle to support.

- Precise depth support with optimal soil compaction.

1. 510 mm or 560 mm diameter discs arranged in two rows. Working depth 3.5 – 13 cm. Maintenance-free disc mounting points allows the cultivator to be operated without additional lubrication. The optimal geometry of the discs ensures extremely productive, high quality work, when incorporating large amounts of plant waste.

Maintenance-free disc mounting points Maintenance-free rubber joints

Individually height-adjustable side discs

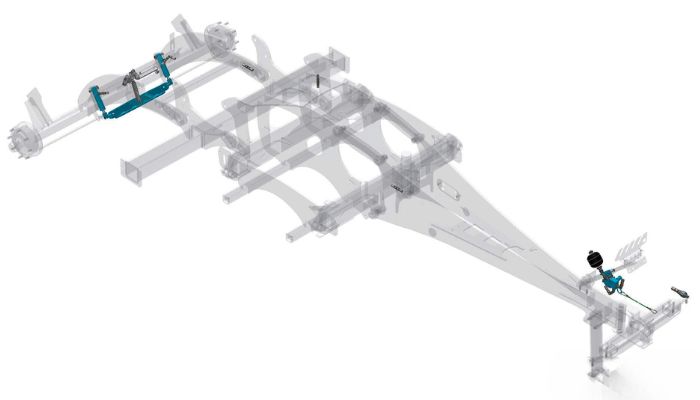

Setting the working depth

Permanent connection of passages

Optional equipment for Softer NS models.

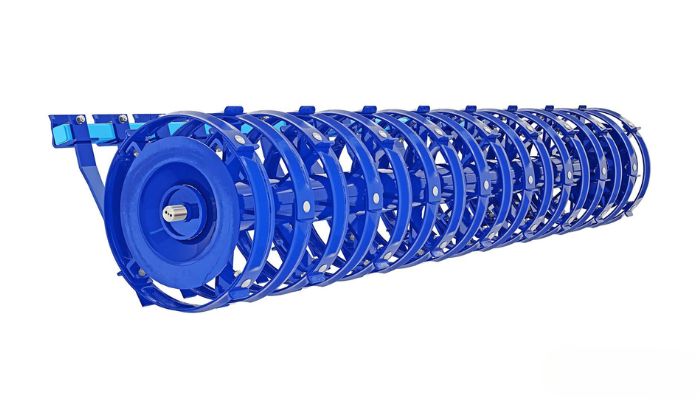

Softer NS mounted disc harrow

Trailed disc harrow Softer PS with Micro Drill

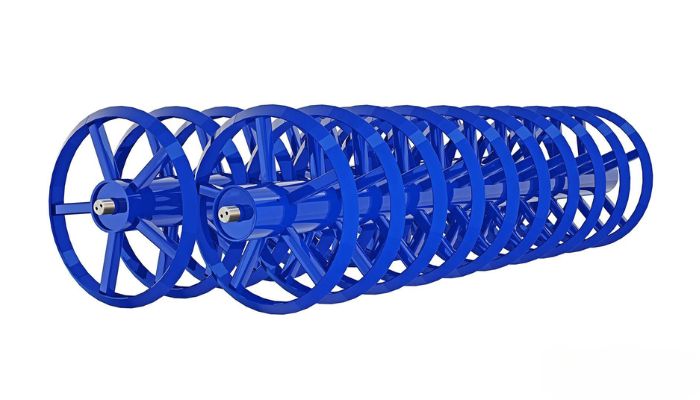

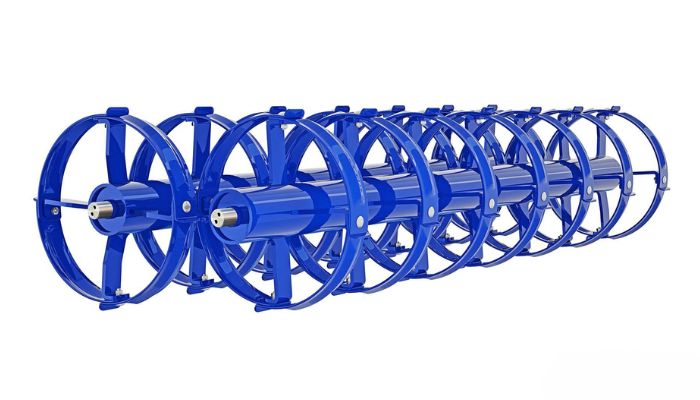

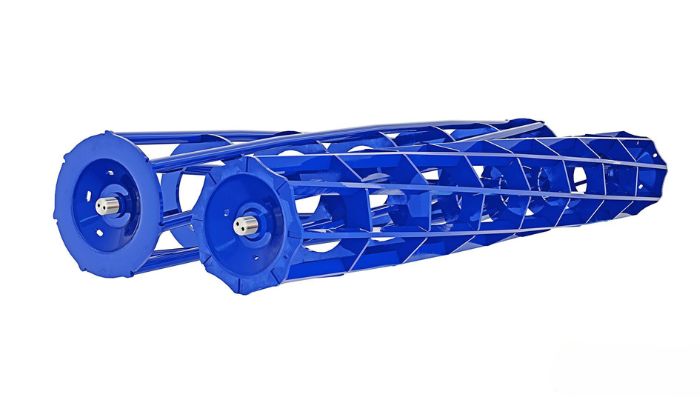

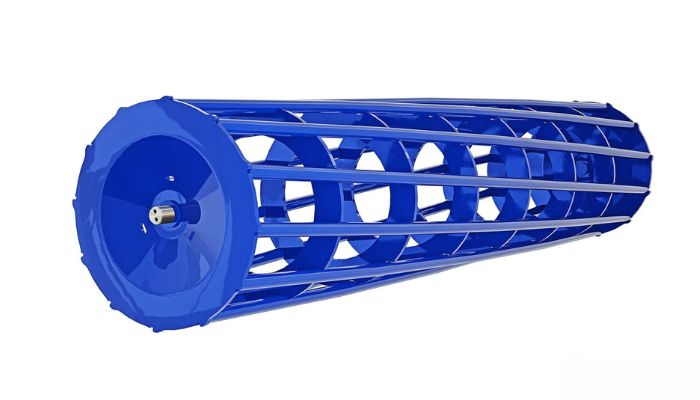

2. Rear roller for breaking up clumps.

3. Optional Micro Drill pneumatic small seed drill.Cut discs

Sturdy construction

Allows the trimmer to be operated without additional lubrication.

For excellent surface adaptation and protection against overloads.Easy to use

For the Softer 3 N hanging model

Individually height-adjustable deflector ensures smooth transition between passesA cleverly designed machine

Roller VR Weight – 175 kg/m

Weight – 160 kg/m

Weight – 220 kg/m

Tubular roller TRS

Disc Ø 560 mm Disc Ø 530 mm Disc Ø 510 mm Disc Ø 510 mm Disc Ø 510 mm

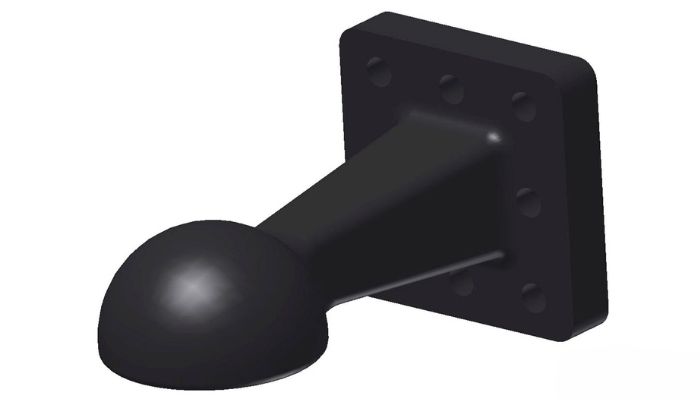

TPH category II and III TPH category III Towing TPH Category III Eyelet for lower hitch Ø 40 mm, Ø 50 mm, Ø 70 mm K80 Ø 80 mm

2 lines 1 circuit air brakes Hydraulic axle control Weight set – 340 kg Pneumatic seeder for sowing small seeds Support wheels. Double support wheels Hydraulic brakesRollers

Weight – 180 kg/m

Weight – 165 kg/m

Diameter – 600 mm

Weight – 100 kg/m

Features Tubular TRS Double DR Double ring DRR Double DFR

Soil crushing ●●○○ ●●●○ ●●●○ ●●●○

Soil pressure (compaction) ●●●○ ●●●○ ●●●● ●●●●

Depth control ●●●○ ●●●● ●●●● ●●●●

Resistance to clogging ●○○○ ●●●○ ●●●● ●●●●

Suitability for rocky soil ●●●○ ●●●○ ●●●○ ●●●○

Suitability for wet soil ●○○○ ●●○○ ●●●● ●●●●

Heavy soils ●●○○ ●●●● ●●●● ●●●●

Average soils ●●●○ ●●●● ●●●● ●●●●

Light soils ●●●● ●●●● ●●●● ●●●●

Features LTX Disk SDR VR Dual DVR

Soil crushing ●●○○ ●●●○ ●●●○ ●●●○

Soil pressure (compaction) ●●●● ●●●● ●●●● ●●●●

Depth control ●●●● ●●●● ●●●● ●●●●

Resistance to clogging ●●●○ ●●●○ ●●●● ●●●●

Suitability for rocky soil ●●●○ ●●●○ ●●●○ ●●●○

Suitability for wet soil ●●●● ●●●● ●●●● ●●●●

Heavy soils ●●●● ●●●● ●●●● ●●●●

Average soils ●●●● ●●●● ●●●● ●●●●

Light soils ●●●○ ●●●○ ●●●● ●●●●

Discs

Hanging/Hitching

(only for Softer 3N model)

(Softer 4.5 NS and Softer 6 NS.

(Optional pins for TPH category 4)Other optional equipment

For Softer 4.5 PS and Softer 6 PS models

Softer 8 PS and Softer 11 PS in standard configuration

Softer 3 for N model

Not available Softer 4.5 PS,

Softer 11 PS in standard configuration

| SOFTER 2.5 N | SOFTER 3 N | SOFTER 3.5 N FIX | SOFTER 4 N FIX | SOFTER 4.5 NS | SOFTER 5 NS | SOFTER 6 NS | SOFTER 8 NS | SOFTER 4 FIX PS | SOFTER 4 PS | SOFTER 4.5 PS | SOFTER 5 PS | SOFTER 6 PS | SOFTER 8 PS | SOFTER 9 PS W | SOFTER 11 PS | SOFTER 12 PS W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | hanging | hanging | hanging | hanging | hanging | hanging | hanging | hanging | trailed | trailed | trailed | trailed | trailed | trailed | trailed | trailed | trailed |

| Working width, mm | 2 550 | 3 000 | 3 500 | 3 990 | 4 470 | 4 950 | 5 910 | 7 400 | 3 990 | 3 990 | 4 470 | 4 950 | 5 910 | 7 360 | 8 320 | 10 690 | 11 670 |

| Transport width, mm | 2 550 | 3 000 | 3 500 | 4 390 | 3 000 | 3 000 | 3000 | 3 000 | 4 330 | 3 000 | 3 000 | 3 000 | 3 000 | 3 000 | 4 000 | 3 000 | 4 000 |

| Transport height, mm | 1 420 | 1 420 | 1 420 | 1 620 | 2 500 | 2 750 | 3 250 | 4 000 | 1 600 | 2 400 | 2 650 | 2 900 | 3 370 | 4 000 | 4 000 | 4 000 | 4 000 |

| Total length, mm | 2 750 | 2 750 | 2 750 | 2 800 | 2 750 | 2 750 | 2 750 | 2 750 | 6 675 | 6 675 | 6 675 | 6 675 | 6 675 | 6 850 | 6 850 | 6 850 | 6 850 |

| Working depth, mm | 35-130 | 35 - 130 | 35 - 130 | 35-130 | 35 - 130 | 35-130 | 35 - 130 | 35-130 | 35 - 130 | 35-130 | 35 - 130 | 35 - 130 | 35 - 130 | 35 - 130 | 35 - 130 | 35 - 130 | 35 - 130 |

| Total number of disks, pcs. | 20 | 24 | 28 | 33 | 37 | 41 | 49 | 61 | 33 | 33 | 37 | 41 | 49 | 61 | 69 | 89 | 97 |

| Disc diameter, mm | 510 / 560 | 510 / 560 | 510 / 560 | 510 / 560 | 510 / 560 | 510 / 560 | 510 / 560 | 510 / 560 | 510 / 560 | 510 / 560 | 510 / 560 | 510 / 560 | 510 / 560 | 510 / 560 | 510 / 560 | 510 / 560 | 510 / 560 |

| Productivity, ha/hour | 2,5-3,8 | 3 - 4,5 | 3,5 - 5,3 | 4-6 | 4,5 - 6,75 | 5-7,5 | 6 - 9 | 8-12 | 4 - 6 | 4-6 | 4,5 - 6,8 | 5 - 7,5 | 6 - 9 | 8 - 12 | 9-13,5 | 11 -16,5 | 12-18,1 |

| Working speed, km/h | 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 |

| Maximum possible slope (°) | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Tire measurements - for transportation | no | no | no | no | no | no | no | no | 400/60-15,5 | 400/60-15,5 | 400/60-15,5 | 400/60-15,5 | 400/60-15,5 | 500/50-17 | 520/50-17 | 500/50-17 | 520/50-17 |

| Brakes | no | no | no | no | no | no | no | no | no | air, 2 circuits | air, 2 circuits | air, 2 circuits | air, 2 circuits | air, 2 circuits | air, 2 circuits | air, 2 circuits | air, 2 circuits |

| Weight, min., kg | 1 800 | 1 980 | 1 980 | 2 700 | 3 200 | 3 450 | 3,900 | 4 770 | 3 600 | 3 900 | 4 000 | 4 350 | 4 990 | 6 700 | 7 600 | 9 200 | 10 920 |

| Tractor power, kW/HP | 65-100 / 90-140 | 80-120/110-165 | 90-140/120-190 | 110-160 / 150-215 | 120-180/160-240 | 150-225 / 200-300 | 150-225/200-300 | 200-300 / 270-405 | 110-160/150-215 | 110-160/150-215 | 120-180/160-240 | 130-190/175-255 | 150-225/200-300 | 200-300/270-405 | 220-320/295-430 | 245-370/330-495 | 280-410/380-550 |

FARMETH – the largest manufacturer of agricultural machinery for tillage and sowing in the Czech Republic. The company, founded in 1992, is growing rapidly and devotes much attention and investment to the development of new technologies.

FARMETH agricultural equipment manufactured by this manufacturer must meet the strictest standards of work quality, reliability and durability. All equipment of this manufacturer 36 months warranty provided.

Products and technologies are developed in close collaboration with customers, research institutes and universities. FARMETH The products feature unique technological solutions, some of which are patented. The company seeks not only to improve product quality and create added value, but also to improve production technologies, productivity, and improve occupational safety and environmental protection.

FARMETH The brand is focused on high-quality products and high value. Major investments in modern production management ensure further quality improvement and more efficient production. The goal is to increase the added value of products and strengthen their competitiveness in all markets.

You can rent this equipment!

We offer the possibility of this technique rent for a day, a week or any other time you want. For rental conditions or other land cultivation, sowing, fodder preparation, and fertilization equipment, please contact our technical department.